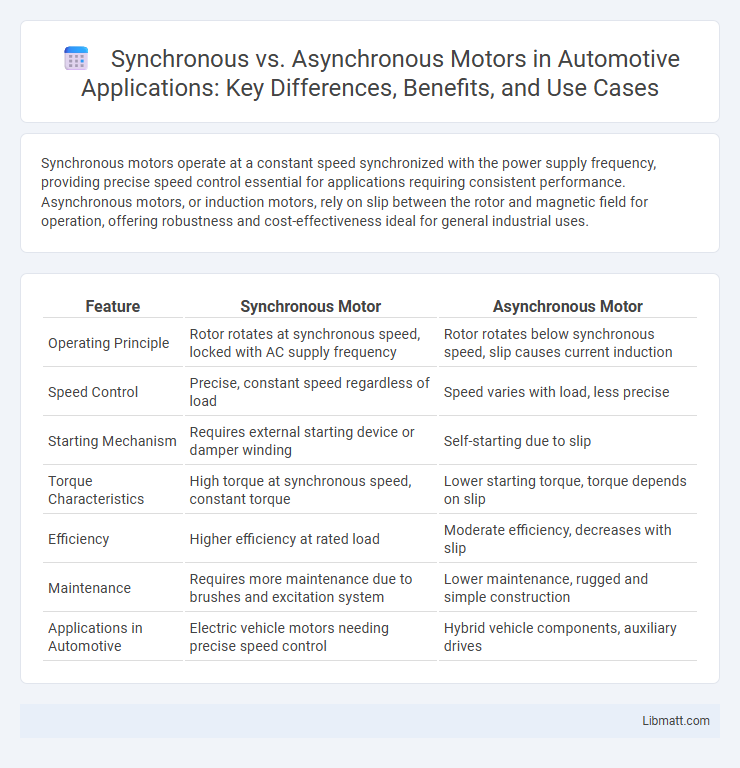

Synchronous motors operate at a constant speed synchronized with the power supply frequency, providing precise speed control essential for applications requiring consistent performance. Asynchronous motors, or induction motors, rely on slip between the rotor and magnetic field for operation, offering robustness and cost-effectiveness ideal for general industrial uses.

Table of Comparison

| Feature | Synchronous Motor | Asynchronous Motor |

|---|---|---|

| Operating Principle | Rotor rotates at synchronous speed, locked with AC supply frequency | Rotor rotates below synchronous speed, slip causes current induction |

| Speed Control | Precise, constant speed regardless of load | Speed varies with load, less precise |

| Starting Mechanism | Requires external starting device or damper winding | Self-starting due to slip |

| Torque Characteristics | High torque at synchronous speed, constant torque | Lower starting torque, torque depends on slip |

| Efficiency | Higher efficiency at rated load | Moderate efficiency, decreases with slip |

| Maintenance | Requires more maintenance due to brushes and excitation system | Lower maintenance, rugged and simple construction |

| Applications in Automotive | Electric vehicle motors needing precise speed control | Hybrid vehicle components, auxiliary drives |

Introduction to Electric Motors

Electric motors convert electrical energy into mechanical energy, essential in various industrial and household applications. Synchronous motors operate at a constant speed synchronized with the supply frequency, making them ideal for precision tasks. Asynchronous motors, also known as induction motors, run at speeds slightly less than the supply frequency, offering simplicity and robustness for general-purpose use.

What is a Synchronous Motor?

A synchronous motor operates at a constant speed determined by the supply frequency and the number of poles, maintaining synchronization with the rotating magnetic field of the stator. It uses a rotor with a permanent magnet or DC-excited winding, producing a magnetic field that locks in step with the stator field, resulting in zero slip during operation. Synchronous motors are widely used in applications requiring precise speed control and constant speed under varying loads, such as in power generation and industrial processes.

What is an Asynchronous Motor?

An asynchronous motor, also known as an induction motor, operates on the principle of electromagnetic induction where the rotor rotates at a speed slightly less than the synchronous speed of the stator's magnetic field. This slip between rotor speed and synchronous speed enables the motor to generate torque without direct electrical connection to the rotor. If you require reliable and durable motor solutions for industrial applications, understanding the characteristics of asynchronous motors is essential for selecting the right equipment.

Key Differences between Synchronous and Asynchronous Motors

Synchronous motors operate at a constant speed synchronized with the supply frequency, while asynchronous motors run at a speed slightly less than the supply frequency, known as slip. Synchronous motors require a DC excitation for the rotor, enabling precise speed control and high efficiency, whereas asynchronous motors rely on electromagnetic induction with no external rotor excitation. The construction complexity and cost of synchronous motors are higher compared to the simpler and more rugged asynchronous motors commonly used in industrial applications.

Working Principle: Synchronous vs Asynchronous Motors

Synchronous motors operate by rotating at a constant speed directly proportional to the supply frequency, with the rotor's magnetic field locked in sync with the stator's rotating magnetic field. Asynchronous motors, also known as induction motors, run at a speed slightly less than the supply frequency, relying on electromagnetic induction to induce current in the rotor and create torque. Understanding the working principle differences between synchronous and asynchronous motors helps you select the most suitable motor type for precise speed control or varying load conditions.

Applications of Synchronous Motors

Synchronous motors are widely used in applications requiring constant speed under varying loads, such as in robotics, conveyor systems, and industrial drives. Their precise speed control and high efficiency make them ideal for power factor correction in large electrical grids and manufacturing plants. If your project demands stable operation and synchronized motion, synchronous motors provide reliable performance in sectors like aerospace and automation.

Applications of Asynchronous Motors

Asynchronous motors, commonly known as induction motors, are widely used in industrial applications such as pumps, fans, conveyors, and compressors due to their robust construction and simple maintenance. Their ability to operate efficiently in variable load conditions makes them ideal for HVAC systems, machine tools, and household appliances. You can rely on asynchronous motors for cost-effective and durable performance in environments requiring continuous duty and high starting torque.

Efficiency and Performance Comparison

Synchronous motors offer higher efficiency due to constant speed operation and reduced rotor losses, making them ideal for applications requiring precise speed control and power factor correction. Asynchronous motors, also known as induction motors, typically have lower initial costs and robust construction but exhibit slightly lower efficiency because of slip and rotor resistance losses. Performance-wise, synchronous motors maintain consistent speed under varying loads, while asynchronous motors experience speed variations proportional to load changes.

Pros and Cons: Synchronous vs Asynchronous Motors

Synchronous motors offer precise speed control and high efficiency with a constant speed operation, making them ideal for applications requiring exact timing, but they are more complex and costly due to the need for a DC excitation system. Asynchronous motors, also known as induction motors, are robust, cost-effective, and easy to maintain, but they suffer from slip and less precise speed control compared to synchronous motors. The choice depends on application requirements such as efficiency, control precision, maintenance costs, and initial investment.

Choosing the Right Motor for Your Application

Selecting the right motor depends on application requirements such as speed control, load type, and efficiency. Synchronous motors excel in precision speed control and constant speed applications, making them ideal for robotics and conveyors. Asynchronous motors, also known as induction motors, offer robustness and cost-effectiveness for variable speed loads like industrial fans and pumps.

Synchronous vs Asynchronous Motor Infographic

libmatt.com

libmatt.com