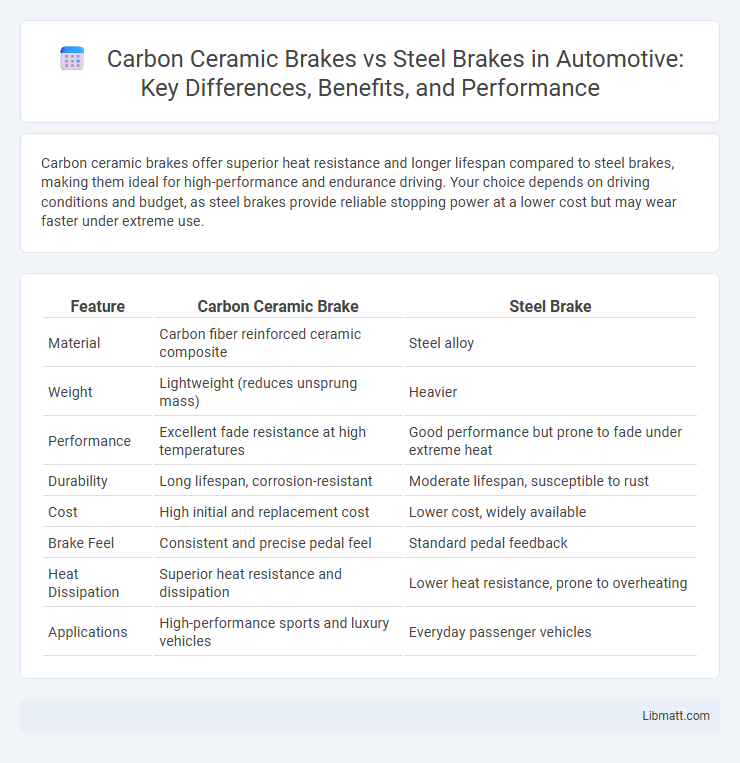

Carbon ceramic brakes offer superior heat resistance and longer lifespan compared to steel brakes, making them ideal for high-performance and endurance driving. Your choice depends on driving conditions and budget, as steel brakes provide reliable stopping power at a lower cost but may wear faster under extreme use.

Table of Comparison

| Feature | Carbon Ceramic Brake | Steel Brake |

|---|---|---|

| Material | Carbon fiber reinforced ceramic composite | Steel alloy |

| Weight | Lightweight (reduces unsprung mass) | Heavier |

| Performance | Excellent fade resistance at high temperatures | Good performance but prone to fade under extreme heat |

| Durability | Long lifespan, corrosion-resistant | Moderate lifespan, susceptible to rust |

| Cost | High initial and replacement cost | Lower cost, widely available |

| Brake Feel | Consistent and precise pedal feel | Standard pedal feedback |

| Heat Dissipation | Superior heat resistance and dissipation | Lower heat resistance, prone to overheating |

| Applications | High-performance sports and luxury vehicles | Everyday passenger vehicles |

Introduction to Carbon Ceramic and Steel Brakes

Carbon ceramic brakes consist of a composite material made from carbon fiber reinforced with ceramic matrix, offering exceptional heat resistance and reduced weight compared to traditional steel brakes. Steel brakes utilize cast iron or steel rotors known for durability, cost-effectiveness, and efficient heat dissipation under normal driving conditions. Carbon ceramic brakes excel in high-performance and endurance applications due to their superior thermal stability, while steel brakes remain widely used for everyday vehicles owing to their affordability and ease of maintenance.

Composition and Material Differences

Carbon ceramic brakes consist of carbon fiber reinforced with ceramic matrix composites, providing lightweight properties and exceptional heat resistance ideal for high-performance applications. Steel brakes, typically made from cast iron or steel alloys, offer durability and affordability but are heavier and less effective at dissipating heat compared to carbon ceramic components. The advanced composite structure of carbon ceramic brakes results in lower thermal expansion and improved wear resistance, essential for extreme braking conditions.

Performance and Stopping Power

Carbon ceramic brakes offer superior performance and stopping power compared to steel brakes, with enhanced heat resistance that prevents brake fade during intense driving conditions. Their lightweight construction reduces rotational mass, improving acceleration and handling responsiveness. Your vehicle benefits from consistently strong and reliable braking performance, especially in high-performance or demanding environments.

Heat Resistance and Fade

Carbon ceramic brakes exhibit superior heat resistance compared to steel brakes, allowing them to maintain optimal performance under extreme temperatures. Their advanced material composition minimizes brake fade during prolonged or aggressive braking, ensuring consistent stopping power. You benefit from enhanced reliability and safety, especially in high-performance or demanding driving conditions.

Weight and Handling Impact

Carbon ceramic brakes weigh significantly less than traditional steel brakes, reducing unsprung mass and improving vehicle responsiveness. The lighter weight enhances handling precision by allowing quicker suspension movements and better tire contact with the road surface. This weight reduction translates to sharper cornering and improved overall driving dynamics, especially in high-performance and racing applications.

Durability and Longevity

Carbon ceramic brakes offer exceptional durability and longevity, often lasting up to 100,000 miles or more under normal driving conditions, significantly outperforming traditional steel brakes. Their resistance to heat and wear reduces the frequency of replacements and maintenance, making them ideal for high-performance vehicles and heavy-duty use. Your investment in carbon ceramic brakes ensures enhanced performance over time while minimizing brake fade and wear-related issues.

Maintenance and Repair

Carbon ceramic brakes require less frequent maintenance compared to steel brakes due to their superior heat resistance and durability, which reduces wear and tear. Repair costs for carbon ceramic brakes are typically higher because of specialized materials and complex manufacturing processes, but they offer longer service life and better performance under extreme conditions. Your choice should consider long-term maintenance savings versus upfront repair expenses based on your driving demands.

Cost Comparison

Carbon ceramic brakes typically cost three to four times more than steel brakes due to advanced materials and manufacturing processes. While steel brakes offer affordability and ease of replacement, carbon ceramic brakes provide longer lifespan and superior performance, potentially reducing long-term maintenance expenses. Evaluating your driving needs will help determine if the upfront investment in carbon ceramic brakes aligns with your cost expectations.

Application: Street vs. Track Use

Carbon ceramic brakes excel in high-performance track applications due to superior heat dissipation, reduced fade, and lightweight construction, ensuring consistent stopping power under extreme conditions. Steel brakes are preferred for street use because they offer reliable performance at lower costs and are less sensitive to temperature variations encountered in daily driving. Choosing between the two depends on specific use cases: carbon ceramics deliver optimal performance on race tracks, while steel brakes suffice for everyday road conditions.

Conclusion: Which Brake is Right for You?

Carbon ceramic brakes offer superior heat resistance, reduced weight, and longer lifespan, making them ideal for high-performance vehicles and enthusiasts seeking enhanced braking efficiency. Steel brakes provide reliable performance at a significantly lower cost, ideal for everyday driving and budget-conscious users. Choosing the right brake depends on driving style, vehicle usage, and budget constraints, with carbon ceramics excelling in extreme conditions and steel brakes proving practical and economical for standard applications.

Carbon ceramic brake vs Steel brake Infographic

libmatt.com

libmatt.com