An idler pulley guides and maintains the routing of a belt without applying tension, ensuring smooth operation of engine components. Your tensioner pulley, however, actively applies pressure to the belt to maintain proper tension, preventing slippage and extending belt life.

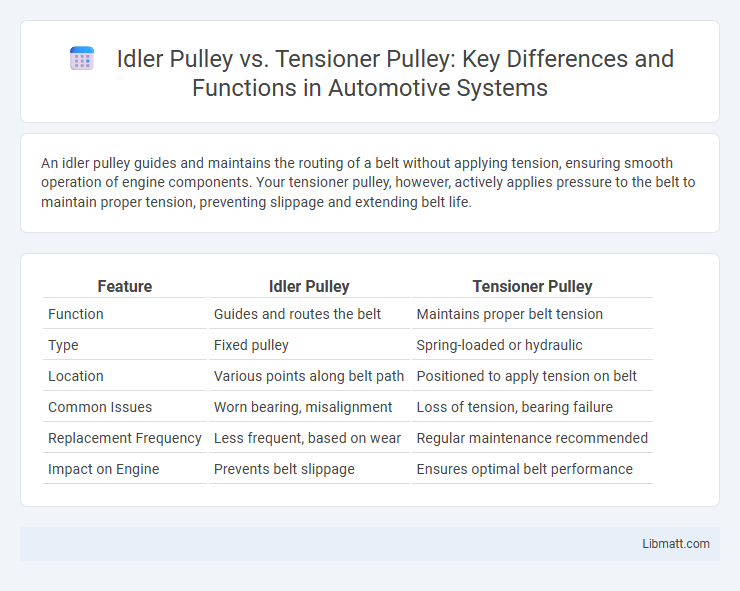

Table of Comparison

| Feature | Idler Pulley | Tensioner Pulley |

|---|---|---|

| Function | Guides and routes the belt | Maintains proper belt tension |

| Type | Fixed pulley | Spring-loaded or hydraulic |

| Location | Various points along belt path | Positioned to apply tension on belt |

| Common Issues | Worn bearing, misalignment | Loss of tension, bearing failure |

| Replacement Frequency | Less frequent, based on wear | Regular maintenance recommended |

| Impact on Engine | Prevents belt slippage | Ensures optimal belt performance |

Introduction to Idler Pulley and Tensioner Pulley

Idler pulleys and tensioner pulleys play critical roles in vehicle belt systems by guiding and maintaining proper tension on the serpentine or timing belts. An idler pulley serves as a simple guide pulley that redirects or routes the belt without applying tension, while a tensioner pulley includes a spring mechanism that automatically adjusts belt tension to prevent slippage and ensure optimal performance. Both components contribute to engine efficiency and longevity by maintaining proper belt alignment and tension.

Key Functions of Idler Pulley

Idler pulleys guide and maintain proper tension on the engine's serpentine or timing belt, ensuring smooth operation and preventing slippage. Unlike tensioner pulleys, idler pulleys do not adjust belt tension but provide a stable route to optimize belt alignment. Your vehicle relies on idler pulleys to reduce wear on belts and other engine components, promoting longevity and efficient performance.

Key Functions of Tensioner Pulley

The tensioner pulley maintains optimal belt tension to prevent slippage and ensure smooth operation of the engine's accessory drive system. It compensates for belt stretch and wear by automatically adjusting tension, enhancing belt longevity and engine performance. Proper function of the tensioner pulley is critical for transmitting power efficiently to components such as the alternator, water pump, and air conditioning compressor.

Structural Differences: Idler vs Tensioner Pulley

Idler pulleys feature a fixed bracket design that maintains belt routing and tension without adjustment capability, while tensioner pulleys incorporate a spring-loaded or hydraulic mechanism that automatically adjusts belt tension for optimal performance. The structural difference lies in the tensioner pulley's ability to adapt to belt stretch and wear, enhancing engine efficiency and longevity, whereas idler pulleys primarily serve to guide or redirect the belt. Understanding these differences helps you identify the right component for proper belt system maintenance and prevents premature wear or failure.

Materials and Design Considerations

Idler pulleys and tensioner pulleys are typically made from high-strength steel or aluminum alloy to withstand pressure and reduce wear, with some incorporating durable nylon or plastic coatings for noise reduction and corrosion resistance. Idler pulleys primarily serve to guide and maintain belt alignment, often designed with smooth surfaces and sealed bearings, while tensioner pulleys include spring-loaded mechanisms to adjust belt tension dynamically, requiring robust construction for consistent performance. Your choice between the two should consider the material durability and specific design features that match the operational demands of your vehicle's belt system.

Common Failures and Symptoms

Idler pulleys commonly fail due to worn-out bearings, resulting in squealing or grinding noises and visible wobbling during operation. Tensioner pulleys often experience spring fatigue or bearing wear, causing belt misalignment, excessive vibration, or belt slippage that reduces engine performance. You should inspect these components promptly if your vehicle exhibits unusual belt noise, loss of power steering, or irregular accessory function.

Installation and Maintenance Requirements

Idler pulleys typically require simpler installation processes, involving straightforward bracket mounting and minimal adjustment, whereas tensioner pulleys demand precise alignment and spring tension calibration to maintain optimal belt tension. Maintenance for idler pulleys mainly involves periodic inspection for bearing wear and belt alignment, while tensioner pulleys require regular checks of spring tension, pulley wear, and proper belt tracking to prevent slippage. Both components benefit from lubrication and timely replacement, but tensioner pulleys usually have a shorter service interval due to their active role in belt tension regulation.

Effects on Belt System Performance

Idler pulleys primarily guide and maintain the routing of the belt without applying tension, ensuring smooth belt operation and preventing misalignment that can cause premature wear. Tensioner pulleys actively apply the correct amount of tension to the belt, optimizing grip and minimizing slippage, which enhances overall system efficiency and longevity. Improper function of either pulley type can lead to belt noise, reduced performance, and potential system failures in automotive or industrial drive systems.

Cost Comparison and Replacement Frequency

Idler pulleys generally cost less than tensioner pulleys, with prices ranging from $20 to $50 compared to $50 to $120 for tensioners due to their simpler design and fewer components. Replacement frequency varies as idler pulleys often last 60,000 to 90,000 miles, while tensioner pulleys, which endure more stress from maintaining belt tension, typically require replacement every 50,000 to 70,000 miles. Maintenance costs for tensioner pulleys tend to be higher, factoring in both parts and labor, since they are critical to belt system performance and may involve additional adjustments during replacement.

Choosing the Right Pulley for Your Vehicle

Selecting the right pulley for your vehicle involves understanding the distinct roles of idler pulleys and tensioner pulleys in the engine's belt system. The idler pulley primarily guides and maintains proper routing of the serpentine belt, ensuring smooth operation without belt slack. The tensioner pulley applies dynamic tension to the belt, compensating for wear and elongation to prevent slipping and maintain optimal engine performance.

Idler Pulley vs Tensioner Pulley Infographic

libmatt.com

libmatt.com