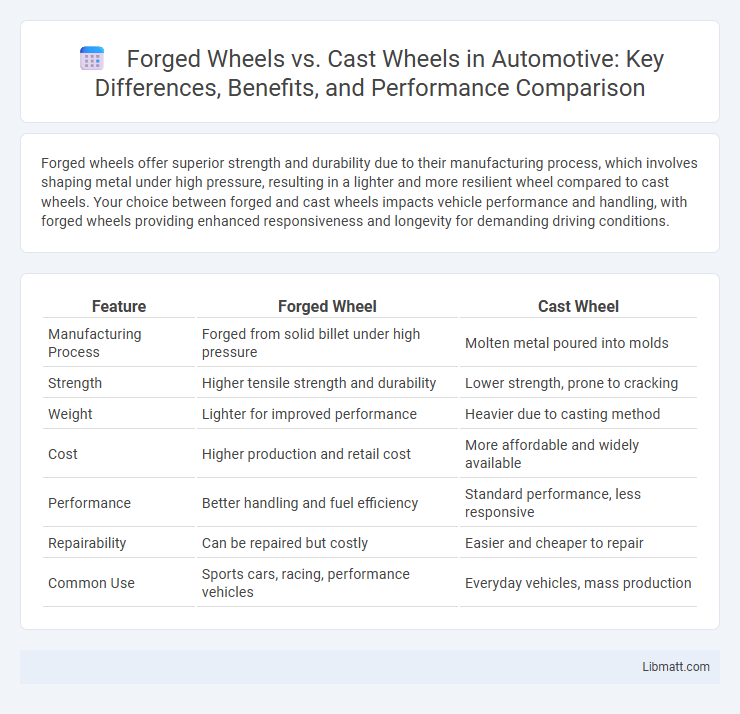

Forged wheels offer superior strength and durability due to their manufacturing process, which involves shaping metal under high pressure, resulting in a lighter and more resilient wheel compared to cast wheels. Your choice between forged and cast wheels impacts vehicle performance and handling, with forged wheels providing enhanced responsiveness and longevity for demanding driving conditions.

Table of Comparison

| Feature | Forged Wheel | Cast Wheel |

|---|---|---|

| Manufacturing Process | Forged from solid billet under high pressure | Molten metal poured into molds |

| Strength | Higher tensile strength and durability | Lower strength, prone to cracking |

| Weight | Lighter for improved performance | Heavier due to casting method |

| Cost | Higher production and retail cost | More affordable and widely available |

| Performance | Better handling and fuel efficiency | Standard performance, less responsive |

| Repairability | Can be repaired but costly | Easier and cheaper to repair |

| Common Use | Sports cars, racing, performance vehicles | Everyday vehicles, mass production |

Introduction to Forged and Cast Wheels

Forged wheels are crafted by compressing a solid block of aluminum under high pressure, resulting in a lightweight, high-strength wheel ideal for performance and durability. Cast wheels are produced by pouring molten aluminum into molds, allowing for more complex designs but typically heavier and less resilient than forged counterparts. Understanding the fundamental differences in manufacturing helps you make an informed choice based on your vehicle's requirements and driving style.

Understanding the Manufacturing Process

Forged wheels are crafted by applying intense pressure to a solid billet of aluminum, resulting in a denser, stronger structure with improved durability and performance. Cast wheels are made by pouring molten aluminum into molds, which allows for more complex designs but can introduce inconsistencies and lower strength compared to forging. Understanding these manufacturing differences helps you make an informed decision based on your priority for strength, weight, and customization options.

Key Differences: Forged vs Cast Wheels

Forged wheels are created by compressing metal under extreme pressure, resulting in a stronger, lighter, and more durable wheel compared to cast wheels, which are made by pouring molten metal into molds. Cast wheels tend to be more affordable but typically have lower tensile strength and are heavier, impacting overall vehicle performance and fuel efficiency. Choosing forged wheels can enhance your driving experience by offering superior strength, weight reduction, and better resistance to impact and stress.

Strength and Durability Comparison

Forged wheels offer superior strength and durability compared to cast wheels due to their manufacturing process, which involves compressing a solid billet of aluminum under high pressure, resulting in a denser and stronger material. Cast wheels, produced by pouring molten aluminum into molds, tend to have micro-porosity and are more prone to cracking under extreme stress. Choosing forged wheels enhances Your vehicle's performance and longevity, especially in demanding driving conditions.

Weight Considerations and Performance Impact

Forged wheels are significantly lighter than cast wheels due to the dense aluminum alloy compression during the forging process, which enhances their strength-to-weight ratio. This weight reduction directly improves vehicle acceleration, braking, and handling by decreasing unsprung mass and rotational inertia. In contrast, cast wheels tend to be heavier and less rigid, potentially compromising performance in high-demand driving scenarios.

Cost Analysis: Forged vs Cast Wheels

Forged wheels typically cost more due to their labor-intensive manufacturing process and higher-quality materials, resulting in superior strength and lighter weight. Cast wheels, produced through a more automated and economical process, offer a budget-friendly alternative with adequate performance for everyday driving. You should weigh upfront expenses against long-term benefits like durability and performance when deciding between forged and cast wheels.

Aesthetics and Customization Options

Forged wheels offer superior aesthetics and customization options due to their precise manufacturing process, allowing for intricate designs and unique finishes that appeal to enthusiasts seeking a personalized look. Cast wheels, while more affordable, generally feature simpler designs and fewer finish choices, making them less customizable. The density and strength of forged wheels enable slimmer spokes and complex shapes, enhancing both visual appeal and performance.

Real-World Applications and Use Cases

Forged wheels are widely used in high-performance and racing vehicles due to their superior strength-to-weight ratio and ability to withstand extreme stress. Cast wheels are common in everyday passenger cars and trucks, offering cost-effective production and a variety of design options suitable for standard driving conditions. Industrial and off-road applications often favor forged wheels for durability under heavy loads and harsh environments.

Maintenance and Lifespan Factors

Forged wheels exhibit superior durability and resistance to cracks, requiring less frequent maintenance compared to cast wheels, which are more prone to corrosion and structural fatigue over time. The dense aluminum alloy and precision manufacturing process of forged wheels enhance their lifespan, often lasting significantly longer under similar driving conditions than cast wheels. Regular inspection and proper care can mitigate wear on both types, but forged wheels generally offer a longer functional lifespan with reduced maintenance needs.

Which Is Best for Your Vehicle?

Forged wheels offer superior strength, reduced weight, and enhanced durability, making them ideal for high-performance vehicles and aggressive driving conditions. Cast wheels are more affordable and provide a wider range of styles, suitable for everyday use or budget-conscious drivers. Choosing the best wheel depends on your vehicle's performance needs, budget, and driving style.

Forged Wheel vs Cast Wheel Infographic

libmatt.com

libmatt.com