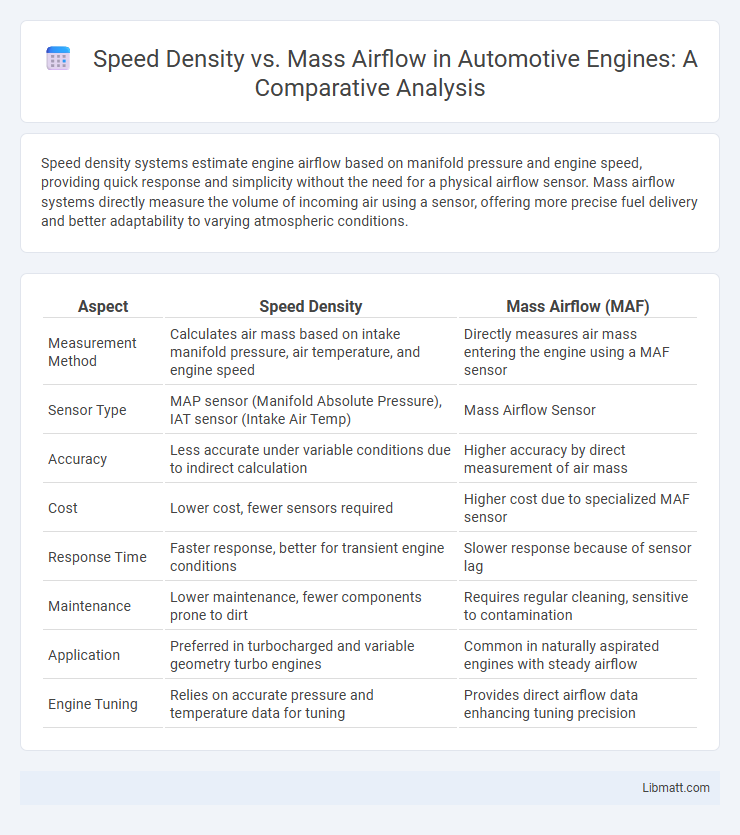

Speed density systems estimate engine airflow based on manifold pressure and engine speed, providing quick response and simplicity without the need for a physical airflow sensor. Mass airflow systems directly measure the volume of incoming air using a sensor, offering more precise fuel delivery and better adaptability to varying atmospheric conditions.

Table of Comparison

| Aspect | Speed Density | Mass Airflow (MAF) |

|---|---|---|

| Measurement Method | Calculates air mass based on intake manifold pressure, air temperature, and engine speed | Directly measures air mass entering the engine using a MAF sensor |

| Sensor Type | MAP sensor (Manifold Absolute Pressure), IAT sensor (Intake Air Temp) | Mass Airflow Sensor |

| Accuracy | Less accurate under variable conditions due to indirect calculation | Higher accuracy by direct measurement of air mass |

| Cost | Lower cost, fewer sensors required | Higher cost due to specialized MAF sensor |

| Response Time | Faster response, better for transient engine conditions | Slower response because of sensor lag |

| Maintenance | Lower maintenance, fewer components prone to dirt | Requires regular cleaning, sensitive to contamination |

| Application | Preferred in turbocharged and variable geometry turbo engines | Common in naturally aspirated engines with steady airflow |

| Engine Tuning | Relies on accurate pressure and temperature data for tuning | Provides direct airflow data enhancing tuning precision |

Introduction to Speed Density and Mass Airflow Systems

Speed density and mass airflow systems are two primary methods used to measure engine air intake for fuel delivery optimization. Speed density calculates airflow using engine speed and manifold pressure sensors, relying on air density estimations, while mass airflow systems directly measure the volume and density of incoming air using a mass airflow sensor, providing precise real-time data. Understanding these differences helps you optimize engine performance and fuel efficiency based on your vehicle's specific setup.

Core Principles: How Speed Density Works

Speed density calculates engine airflow using intake manifold pressure and air temperature instead of a physical sensor, relying on the ideal gas law to estimate air mass entering the engine. This method uses engine speed (RPM) and manifold absolute pressure (MAP) data combined with a volumetric efficiency table to derive precise fuel delivery. Understanding how speed density works helps you optimize tuning, especially when a mass airflow sensor is not practical or fails under certain conditions.

Core Principles: How Mass Airflow Works

Mass airflow sensors measure the volume and density of air entering the engine by detecting the mass flow rate using a heated wire or film element, which changes resistance based on temperature variations caused by the incoming air. This real-time data enables precise fuel delivery adjustments for optimal combustion and engine performance. Your engine management system relies on this accurate measurement to maintain efficient air-fuel ratios compared to speed density systems, which estimate airflow from manifold pressure and engine speed.

Key Sensors: MAP vs MAF Explained

The speed density system uses a Manifold Absolute Pressure (MAP) sensor along with Intake Air Temperature (IAT) and engine RPM to calculate air mass entering the engine by estimating air density. In contrast, the mass airflow (MAF) system directly measures the volume and density of incoming air using a MAF sensor, resulting in more precise fuel metering for varying engine conditions. MAP sensors provide cost-effective and simpler setups ideal for forced induction engines, while MAF sensors offer improved accuracy in naturally aspirated engines by directly assessing airflow.

Performance Impact: Power and Response

Speed density systems rely on manifold pressure and engine speed to estimate airflow, resulting in a more immediate throttle response and consistent power delivery under varying conditions. Mass airflow sensors measure actual air entering the engine, allowing for precise fuel metering that enhances peak power and overall efficiency. Performance tuning often balances the responsiveness of speed density with the accuracy of mass airflow to optimize both power output and throttle responsiveness.

Tuning Flexibility and Adaptability

Speed density systems provide greater tuning flexibility by relying on manifold absolute pressure (MAP) and intake air temperature to calculate air mass, allowing precise adjustments for varying engine conditions without hardware changes. Mass airflow (MAF) sensors offer accurate real-time measurement of incoming air, which simplifies tuning but can limit adaptability when modifying engine components or forced induction setups. Speed density setups adapt better to significant engine modifications and extreme conditions, making them preferred in high-performance tuning scenarios, while MAF systems excel in ease of use for stock or mildly tuned engines.

Reliability and Maintenance Considerations

Speed density systems rely on engine sensors like manifold absolute pressure (MAP) and intake air temperature (IAT) to calculate airflow, making them less susceptible to sensor contamination but highly dependent on sensor accuracy and calibration. Mass airflow (MAF) sensors directly measure incoming air volume, providing more precise fuel delivery but requiring regular cleaning or replacement to maintain reliability, as dirt and debris can degrade sensor performance. Your choice between these systems should consider the trade-off between the lower maintenance of speed density and the high accuracy but upkeep needs of MAF sensors.

Cost and Installation Complexity

Speed density systems tend to be more cost-effective and simpler to install because they rely on existing engine sensors like the manifold absolute pressure (MAP) and intake air temperature sensors, eliminating the need for additional hardware. Mass airflow (MAF) systems require a specialized sensor positioned in the intake tract, increasing both the initial cost and installation complexity due to the need for precise placement and calibration. This makes speed density preferred for budget-conscious or custom tuning setups where minimizing hardware and installation time is critical.

Best Applications for Each System

Speed density systems excel in applications with limited engine modifications, offering reliable fuel delivery using manifold absolute pressure (MAP) and intake air temperature sensors, making them ideal for stock or mildly tuned engines. Mass airflow (MAF) systems provide precise air measurement directly through the sensor, which enhances performance in highly modified or turbocharged engines where airflow characteristics fluctuate significantly. For racing or high-performance vehicles with variable boost and airflow, MAF systems deliver better adaptability, while speed density remains cost-effective and simpler for consistent, lower-demand environments.

Choosing the Right System for Your Build

Speed density systems rely on manifold pressure and engine RPM to calculate air intake, offering precise fuel delivery and better response in high-performance naturally aspirated engines. Mass airflow systems directly measure the actual volume of incoming air, providing accurate fueling for diverse conditions and easier tuning in forced induction setups. Selecting the right system depends on your build's characteristics: speed density excels in tightly controlled, naturally aspirated engines, while mass airflow is preferable for turbocharged or supercharged builds requiring real-time airflow measurement.

Speed density vs Mass airflow Infographic

libmatt.com

libmatt.com