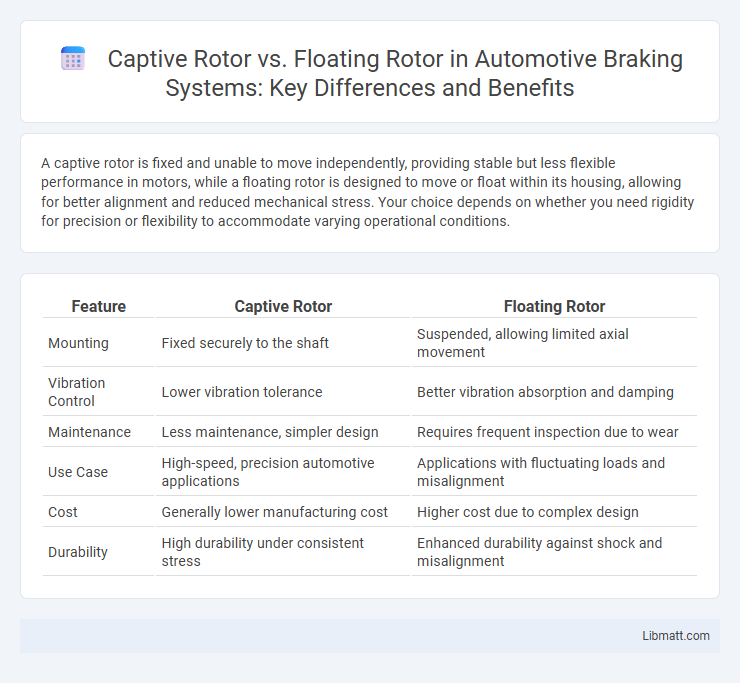

A captive rotor is fixed and unable to move independently, providing stable but less flexible performance in motors, while a floating rotor is designed to move or float within its housing, allowing for better alignment and reduced mechanical stress. Your choice depends on whether you need rigidity for precision or flexibility to accommodate varying operational conditions.

Table of Comparison

| Feature | Captive Rotor | Floating Rotor |

|---|---|---|

| Mounting | Fixed securely to the shaft | Suspended, allowing limited axial movement |

| Vibration Control | Lower vibration tolerance | Better vibration absorption and damping |

| Maintenance | Less maintenance, simpler design | Requires frequent inspection due to wear |

| Use Case | High-speed, precision automotive applications | Applications with fluctuating loads and misalignment |

| Cost | Generally lower manufacturing cost | Higher cost due to complex design |

| Durability | High durability under consistent stress | Enhanced durability against shock and misalignment |

Introduction to Captive and Floating Rotors

Captive rotors are fixed in place within a device, providing stability and precise control by limiting their movement to a predetermined axis. Floating rotors, in contrast, are designed to move freely within a magnetic or fluid field, enhancing responsiveness and reducing mechanical friction. This distinction impacts the efficiency and application of rotors in electric motors, generators, and gyroscopic instruments.

Overview of Rotor Types in Braking Systems

Captive rotors are fixed securely within the braking assembly, providing consistent friction and reliable stopping power essential for industrial machinery and automotive applications. Floating rotors, designed to move slightly within their mounting points, enhance heat dissipation and reduce warping under heavy braking conditions, improving brake longevity. Your choice between captive and floating rotors depends on performance needs, with floating rotors favored in high-performance or heavy-duty systems for superior thermal management.

Captive Rotor: Definition and Design

A captive rotor is a component designed to remain securely fixed within the stator while allowing rotational motion, commonly used in axial flux motors to ensure stability and precise alignment. Its design features include robust mounting structures and bearings that restrict axial or radial movement, enhancing the motor's reliability and performance. This configuration facilitates efficient torque transfer by maintaining consistent magnetic flux interaction between rotor and stator.

Floating Rotor: Definition and Structure

A floating rotor is an innovative electromechanical component designed to move freely on a shaft within a motor or generator, supported by magnetic or mechanical bearings for minimal friction. This rotor structure allows for reduced wear and enhanced dynamic balance, enabling higher operational speeds and improved efficiency in applications such as flywheel energy storage and precision machinery. Its floating design contrasts with captive rotors, which are rigidly fixed and constrained, leading to different performance and maintenance characteristics.

Key Differences Between Captive and Floating Rotors

Captive rotors are fixed within the stator housing, providing stable alignment and reduced mechanical wear, while floating rotors operate freely, allowing for axial or radial movement to accommodate load variations and misalignment. The captive rotor design enhances durability and precision in applications requiring consistent torque transmission, whereas floating rotors offer improved shock absorption and adaptability in dynamic environments. Key differences include the degree of mechanical freedom, alignment stability, and the rotor's ability to compensate for mechanical stress or thermal expansion.

Performance Implications: Captive vs Floating Rotors

Performance implications of captive rotors show increased stability and durability due to their fixed position, minimizing mechanical wear and enhancing precision in high-speed applications. Floating rotors offer improved dynamic response and reduced vibration by allowing limited movement to absorb shocks, which is beneficial in variable load conditions and fluctuating speeds. Your choice depends on whether consistent performance under steady conditions (captive) or adaptability to dynamic environments (floating) is prioritized.

Durability and Maintenance Considerations

Captive rotors offer increased durability due to their fixed position, minimizing wear and reducing the frequency of maintenance requirements, making them ideal for applications with consistent load conditions. Floating rotors, while providing superior shock absorption and flexibility, demand more regular inspection and maintenance to address potential misalignment and wear caused by their variable positioning. The choice between captive and floating rotors significantly impacts lifecycle costs, with captive rotors favoring low-maintenance environments and floating rotors benefiting dynamic systems requiring enhanced shock resilience.

Heat Dissipation and Warping Resistance

Captive rotors excel in heat dissipation due to their rigid mounting, allowing efficient heat transfer and minimizing thermal buildup during operation. Floating rotors, while offering superior warping resistance thanks to flexible mounting that accommodates shaft misalignment and thermal expansion, may experience less effective heat dissipation. Your choice between these rotor designs should consider the specific thermal management and structural durability requirements of your application.

Application Suitability: Choosing the Right Rotor

Captive rotors are ideal for applications requiring precise alignment and stability, commonly used in industrial machinery and precision instruments. Floating rotors offer superior flexibility and vibration damping, making them suitable for high-speed turbines and dynamic systems. Your choice depends on the application's need for rigidity versus adaptability to operational stresses.

Cost Comparison and Value Analysis

Captive rotors typically offer lower initial costs due to simplified manufacturing and installation, making them budget-friendly for standard applications. Floating rotors, while more expensive upfront because of advanced design and materials, provide superior efficiency and longevity, resulting in better value over time. Your choice should balance immediate expenses against long-term performance benefits and maintenance savings.

captive rotor vs floating rotor Infographic

libmatt.com

libmatt.com