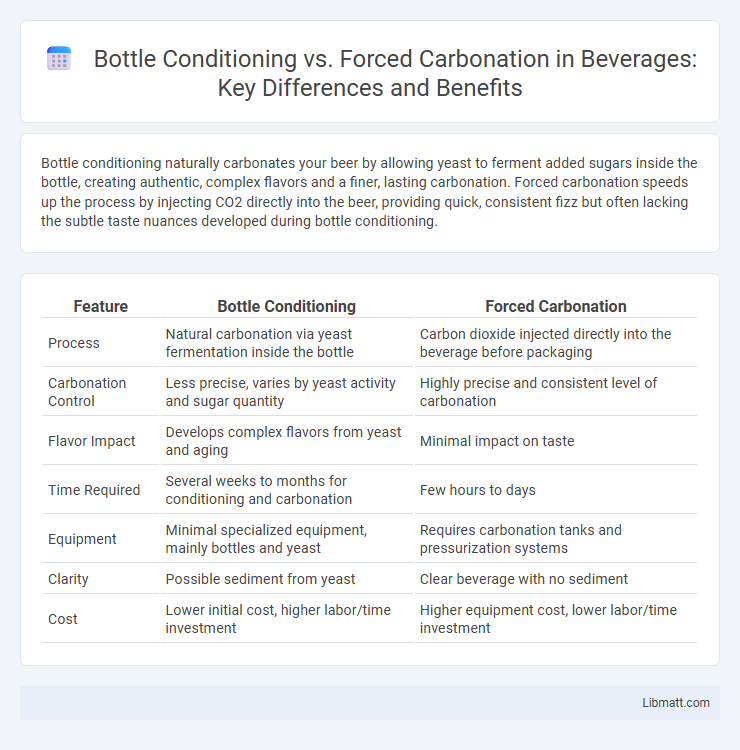

Bottle conditioning naturally carbonates your beer by allowing yeast to ferment added sugars inside the bottle, creating authentic, complex flavors and a finer, lasting carbonation. Forced carbonation speeds up the process by injecting CO2 directly into the beer, providing quick, consistent fizz but often lacking the subtle taste nuances developed during bottle conditioning.

Table of Comparison

| Feature | Bottle Conditioning | Forced Carbonation |

|---|---|---|

| Process | Natural carbonation via yeast fermentation inside the bottle | Carbon dioxide injected directly into the beverage before packaging |

| Carbonation Control | Less precise, varies by yeast activity and sugar quantity | Highly precise and consistent level of carbonation |

| Flavor Impact | Develops complex flavors from yeast and aging | Minimal impact on taste |

| Time Required | Several weeks to months for conditioning and carbonation | Few hours to days |

| Equipment | Minimal specialized equipment, mainly bottles and yeast | Requires carbonation tanks and pressurization systems |

| Clarity | Possible sediment from yeast | Clear beverage with no sediment |

| Cost | Lower initial cost, higher labor/time investment | Higher equipment cost, lower labor/time investment |

Introduction to Carbonation Methods

Bottle conditioning involves natural carbonation by adding yeast and sugar to bottles, allowing CO2 to develop over time during fermentation, resulting in complex flavors and a slight sediment. Forced carbonation uses pressurized CO2 injected directly into the beer in kegs, providing faster and more controllable carbonation levels without additional fermentation. Both methods affect the beer's mouthfeel and carbonation profile, with bottle conditioning favored for traditional styles and forced carbonation preferred for speed and consistency.

What is Bottle Conditioning?

Bottle conditioning is a natural carbonation process in brewing where yeast and sugar are added to beer before sealing it in bottles, allowing fermentation to produce carbon dioxide inside the bottle. This method enhances flavor complexity and carbonation retention as the yeast continues to interact with the beer. Understanding bottle conditioning helps you achieve desired effervescence and taste without relying on external carbonation systems.

Understanding Forced Carbonation

Forced carbonation involves injecting carbon dioxide directly into beer under pressure, allowing brewers to control carbonation levels precisely and rapidly. This method reduces the risk of bottle explosions and sediment from yeast compared to bottle conditioning, making it ideal for commercial production. The CO2 pressure is regulated using kegs or carbonating tanks, ensuring consistent carbonation and faster turnaround times.

Key Differences Between the Two Methods

Bottle conditioning involves natural carbonation by adding yeast and sugar to beer before sealing, resulting in a gradual buildup of CO2 and enhanced flavor complexity. Forced carbonation uses pressurized CO2 injected directly into the beer, allowing for immediate carbonation control and consistent results. Your choice affects flavor profile, carbonation speed, and equipment needs, with bottle conditioning being more traditional and time-intensive, while forced carbonation offers precision and efficiency.

Advantages of Bottle Conditioning

Bottle conditioning offers natural carbonation by allowing yeast to ferment sugars inside the bottle, enhancing beer flavor complexity and mouthfeel. This method provides a longer shelf life through continued yeast activity, which can improve taste stability over time. By choosing bottle conditioning, you benefit from an artisanal, traditional process that creates unique, naturally carbonated beverages without the need for external CO2 sources.

Benefits of Forced Carbonation

Forced carbonation offers precise control over carbonation levels, ensuring consistent bubbles and mouthfeel in every batch. It significantly reduces the time needed to carbonate your beer compared to traditional bottle conditioning, allowing faster distribution and consumption. Your brewing process becomes more efficient and predictable, especially when aiming for a professional and consistent product.

Flavor Impact: Bottle Conditioning vs Forced Carbonation

Bottle conditioning enhances flavor complexity by allowing natural yeast fermentation to develop subtle esters and carbonation nuances, resulting in a richer, more authentic taste profile. Forced carbonation introduces CO2 directly, producing a cleaner, more consistent carbonation but with a less complex flavor compared to bottle-conditioned beer. Your choice between the two affects the depth and character of the beer's flavor, with bottle conditioning offering a more dynamic sensory experience.

Equipment and Time Requirements

Bottle conditioning requires minimal equipment, utilizing fermentation-capable bottles and priming sugar, but demands a longer aging period of 2 to 4 weeks for natural carbonation to develop. Forced carbonation involves specialized tools such as a CO2 tank, regulator, and keg system, enabling carbonation within 1 to 3 days by pressurizing beer directly. The trade-off between the two methods hinges on equipment availability and desired turnaround time for carbonation.

Common Mistakes and Troubleshooting

Bottle conditioning often leads to inconsistent carbonation due to uneven yeast distribution or incorrect priming sugar amounts, causing over- or under-carbonation. Forced carbonation issues typically stem from improper CO2 pressure settings or insufficient purging of oxygen, resulting in off-flavors or flat beer. Regular monitoring of carbonation levels, precise measurement of priming sugar, and maintaining proper CO2 pressure can effectively prevent these common mistakes.

Which Carbonation Method is Right for You?

Choosing between bottle conditioning and forced carbonation depends on your brewing goals and equipment availability. Bottle conditioning offers natural carbonation through yeast fermentation, adding complex flavors but requiring longer aging time and careful monitoring. Forced carbonation provides precise control over CO2 levels and faster carbonation, ideal for brewers prioritizing consistency and efficiency in their production process.

Bottle conditioning vs forced carbonation Infographic

libmatt.com

libmatt.com