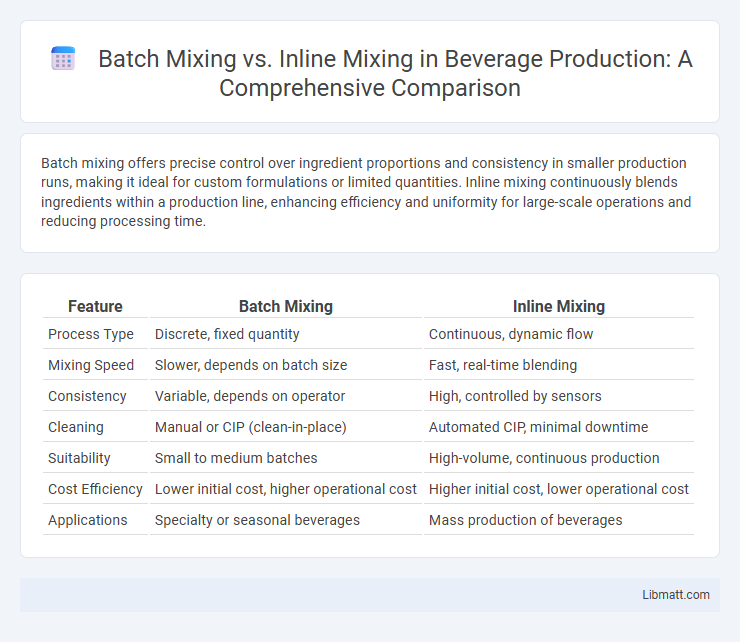

Batch mixing offers precise control over ingredient proportions and consistency in smaller production runs, making it ideal for custom formulations or limited quantities. Inline mixing continuously blends ingredients within a production line, enhancing efficiency and uniformity for large-scale operations and reducing processing time.

Table of Comparison

| Feature | Batch Mixing | Inline Mixing |

|---|---|---|

| Process Type | Discrete, fixed quantity | Continuous, dynamic flow |

| Mixing Speed | Slower, depends on batch size | Fast, real-time blending |

| Consistency | Variable, depends on operator | High, controlled by sensors |

| Cleaning | Manual or CIP (clean-in-place) | Automated CIP, minimal downtime |

| Suitability | Small to medium batches | High-volume, continuous production |

| Cost Efficiency | Lower initial cost, higher operational cost | Higher initial cost, lower operational cost |

| Applications | Specialty or seasonal beverages | Mass production of beverages |

Introduction to Mixing Technologies

Batch mixing involves combining ingredients in a single vessel for a set period, allowing precise control over uniformity and consistency in small to medium production runs. Inline mixing integrates ingredients continuously through a pipeline system, optimizing efficiency and scalability in high-volume manufacturing processes. Both technologies leverage advanced mechanical designs, such as static or dynamic mixers, to ensure homogenous blending tailored to specific industrial applications.

What is Batch Mixing?

Batch mixing refers to the process of combining ingredients in a single, controlled quantity or batch, allowing precise formulation and consistent quality in manufacturing applications such as pharmaceuticals, food production, and chemical processing. This method offers flexibility in handling different recipes and is ideal for smaller production volumes or when product customization is required. Unlike continuous inline mixing, batch mixing ensures thorough blending by allowing ingredients to be mixed for a set period before discharge.

What is Inline Mixing?

Inline mixing is a continuous process where ingredients are combined directly within a pipeline, ensuring consistent blending as materials flow through the system. This method enhances efficiency by reducing mixing time and minimizing manual handling compared to traditional batch mixing, where ingredients are combined in separate containers. Inline mixers are ideal for applications requiring precise control and uniformity, such as chemical processing, food production, and pharmaceuticals.

Key Differences Between Batch and Inline Mixing

Batch mixing involves processing a fixed quantity of materials in a container, allowing precise control over ingredient proportions and flexibility for varied formulations. Inline mixing continuously blends components directly within a pipeline, offering rapid processing, consistent product quality, and efficient scalability for large-volume production. The choice between batch and inline mixing hinges on factors such as production volume, process control, mixing speed, and product uniformity requirements.

Benefits of Batch Mixing

Batch mixing offers precise control over ingredient proportions, ensuring consistent product quality for each batch. It allows flexibility in processing different formulations with easy adjustments between batches. Your production process benefits from better quality assurance and simplified troubleshooting due to the discrete nature of each batch.

Advantages of Inline Mixing

Inline mixing offers continuous processing, which enhances production efficiency and reduces downtime compared to batch mixing. It provides consistent product quality by maintaining uniform mixing conditions and minimizing operator error. Inline mixing systems are space-saving and integrate seamlessly with automated production lines, supporting higher throughput and scalability.

Applications Best Suited for Batch Mixing

Batch mixing is best suited for applications requiring precise control over ingredient proportions and flexibility in small to medium production runs, such as specialty chemicals, pharmaceuticals, and custom food formulations. It allows for thorough mixing of complex formulations with varying viscosities and ingredient types, making it ideal for product development and batch testing. Your process benefits from batch mixing when consistency and customization per batch are essential for quality outcomes.

Industries Favoring Inline Mixing

Industries favoring inline mixing include pharmaceuticals, food and beverage, and chemical manufacturing due to its continuous, efficient process and precise control over product consistency. Inline mixing minimizes contamination risks and reduces processing time, making it ideal for large-scale production environments requiring high throughput. Your choice of inline mixing can significantly enhance operational efficiency and product quality in these sectors.

Cost and Efficiency Considerations

Batch mixing offers lower initial equipment costs and flexibility for small to medium production runs, but it incurs higher labor and downtime expenses for cleaning and reloading between batches. Inline mixing, while requiring higher upfront investment in continuous processing equipment, significantly improves efficiency by reducing labor costs and minimizing material waste through consistent, uninterrupted production. Industries with high-volume demands benefit from inline mixing's cost savings in energy and time, whereas batch mixing suits applications needing frequent formulation changes.

Choosing the Right Mixing Method for Your Process

Batch mixing offers precise control over ingredient proportions and is ideal for small to medium production runs requiring high uniformity. Inline mixing provides continuous processing with consistent blending quality suitable for large-scale operations and fast throughput. Selecting the right mixing method depends on factors such as production volume, process flexibility, product consistency, and equipment integration requirements.

Batch mixing vs inline mixing Infographic

libmatt.com

libmatt.com