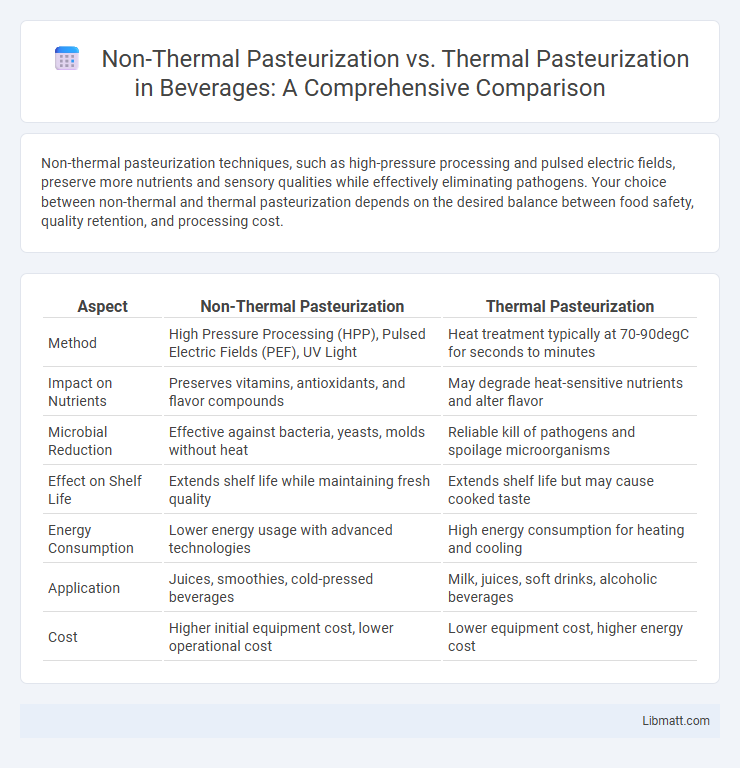

Non-thermal pasteurization techniques, such as high-pressure processing and pulsed electric fields, preserve more nutrients and sensory qualities while effectively eliminating pathogens. Your choice between non-thermal and thermal pasteurization depends on the desired balance between food safety, quality retention, and processing cost.

Table of Comparison

| Aspect | Non-Thermal Pasteurization | Thermal Pasteurization |

|---|---|---|

| Method | High Pressure Processing (HPP), Pulsed Electric Fields (PEF), UV Light | Heat treatment typically at 70-90degC for seconds to minutes |

| Impact on Nutrients | Preserves vitamins, antioxidants, and flavor compounds | May degrade heat-sensitive nutrients and alter flavor |

| Microbial Reduction | Effective against bacteria, yeasts, molds without heat | Reliable kill of pathogens and spoilage microorganisms |

| Effect on Shelf Life | Extends shelf life while maintaining fresh quality | Extends shelf life but may cause cooked taste |

| Energy Consumption | Lower energy usage with advanced technologies | High energy consumption for heating and cooling |

| Application | Juices, smoothies, cold-pressed beverages | Milk, juices, soft drinks, alcoholic beverages |

| Cost | Higher initial equipment cost, lower operational cost | Lower equipment cost, higher energy cost |

Introduction to Pasteurization Methods

Non-thermal pasteurization methods such as high-pressure processing (HPP), pulsed electric fields (PEF), and ultraviolet (UV) treatment offer innovative alternatives to traditional thermal pasteurization by inactivating microorganisms without applying heat. Thermal pasteurization relies on heating food products to specific temperatures to destroy pathogens and extend shelf life, often impacting sensory qualities and nutrient content. Advances in non-thermal technologies preserve food freshness and nutritional value while ensuring safety, making them increasingly popular in the food processing industry.

Defining Thermal Pasteurization

Thermal pasteurization involves heating liquids or foods to a specific temperature for a set period to eliminate harmful microorganisms and extend shelf life. This method relies on direct heat application, typically ranging from 60degC to 85degC, making it effective for products like milk, juice, and eggs. Your choice between non-thermal and thermal pasteurization depends on factors such as preserving nutritional quality and meeting safety standards.

Understanding Non-Thermal Pasteurization

Non-thermal pasteurization uses advanced technologies such as high-pressure processing (HPP), pulsed electric fields (PEF), or ultraviolet (UV) light to eliminate pathogens without heat, preserving the nutritional quality and sensory attributes of your food better than thermal methods. Unlike thermal pasteurization, which relies on high temperatures to kill microbes, non-thermal techniques maintain the structural integrity and bioactive compounds in beverages and fresh produce. This approach offers a safer alternative by reducing harmful microorganisms while extending shelf life and maintaining freshness.

Key Technologies in Non-Thermal Pasteurization

Key technologies in non-thermal pasteurization include high-pressure processing (HPP), pulsed electric fields (PEF), and ultraviolet (UV) light treatment, which effectively inactivate microorganisms without using heat. HPP utilizes pressures up to 600 MPa to disrupt microbial cell membranes, preserving sensory and nutritional qualities. PEF applies short bursts of high voltage to alter cell permeability, while UV light targets microbial DNA, ensuring safety with minimal impact on food texture and flavor.

Efficiency and Effectiveness: Thermal vs Non-Thermal

Thermal pasteurization relies on high temperatures to eliminate pathogens and spoilage microorganisms effectively, ensuring food safety and extended shelf life but potentially compromising sensory quality and nutrient content. Non-thermal pasteurization methods such as high-pressure processing (HPP), pulsed electric fields (PEF), and UV treatment maintain nutritional integrity and sensory attributes while achieving microbial inactivation, though their efficiency may vary depending on food matrix and target organisms. The choice between thermal and non-thermal pasteurization balances the need for microbial safety, retention of food quality, and processing costs.

Impact on Nutritional Quality and Taste

Non-thermal pasteurization methods such as high-pressure processing (HPP) and pulsed electric fields (PEF) better preserve the nutritional quality and flavor of foods compared to thermal pasteurization, which often degrades heat-sensitive vitamins and alters taste profiles. Thermal pasteurization exposes foods to elevated temperatures that can reduce vitamin C, B-complex vitamins, and affect delicate flavor compounds, resulting in a cooked or altered taste. You can retain more natural nutrients and fresh taste by choosing products treated with non-thermal pasteurization technologies.

Safety and Microbial Inactivation

Non-thermal pasteurization methods such as high-pressure processing (HPP) and pulsed electric fields (PEF) effectively inactivate pathogens like Salmonella and Listeria while preserving nutritional and sensory qualities. Thermal pasteurization relies on heat to destroy microbes but can cause nutrient degradation and off-flavors due to protein denaturation and Maillard reactions. Studies show non-thermal technologies maintain microbial safety with minimal impact on food bioactive compounds, enhancing product quality without compromising safety standards.

Environmental Impact and Energy Consumption

Non-thermal pasteurization methods, such as high-pressure processing (HPP) and pulsed electric fields (PEF), significantly reduce energy consumption and greenhouse gas emissions compared to traditional thermal pasteurization by eliminating the need for prolonged heating. Thermal pasteurization relies on sustained high temperatures, which demand substantial energy input and contribute to a larger carbon footprint. Implementing non-thermal techniques supports sustainable food processing by lowering environmental impact through efficient energy use and reduced resource depletion.

Industry Applications and Product Suitability

Non-thermal pasteurization methods, such as high-pressure processing (HPP) and pulsed electric fields (PEF), are extensively used in the beverage, dairy, and juice industries for preserving fresh flavor, nutrients, and extending shelf life without heat damage. Thermal pasteurization remains the industry standard for liquid foods like milk and canned products, offering reliable microbial inactivation but sometimes compromising sensory qualities and nutrient content. Selecting between non-thermal and thermal pasteurization depends on product sensitivity, desired shelf life, and processing cost considerations, with non-thermal techniques favored for premium, heat-sensitive products.

Future Trends in Pasteurization Technology

Emerging advancements in non-thermal pasteurization, including high-pressure processing (HPP) and pulsed electric fields (PEF), demonstrate enhanced preservation of nutritional quality and sensory attributes compared to conventional thermal pasteurization. Research indicates increasing adoption of these technologies in dairy, juice, and ready-to-eat food sectors due to consumer demand for minimally processed products with extended shelf life. Integration of smart sensors and AI-driven process controls further optimizes pasteurization efficiency, reducing energy consumption and ensuring food safety compliance in future production lines.

Non-thermal pasteurization vs thermal pasteurization Infographic

libmatt.com

libmatt.com