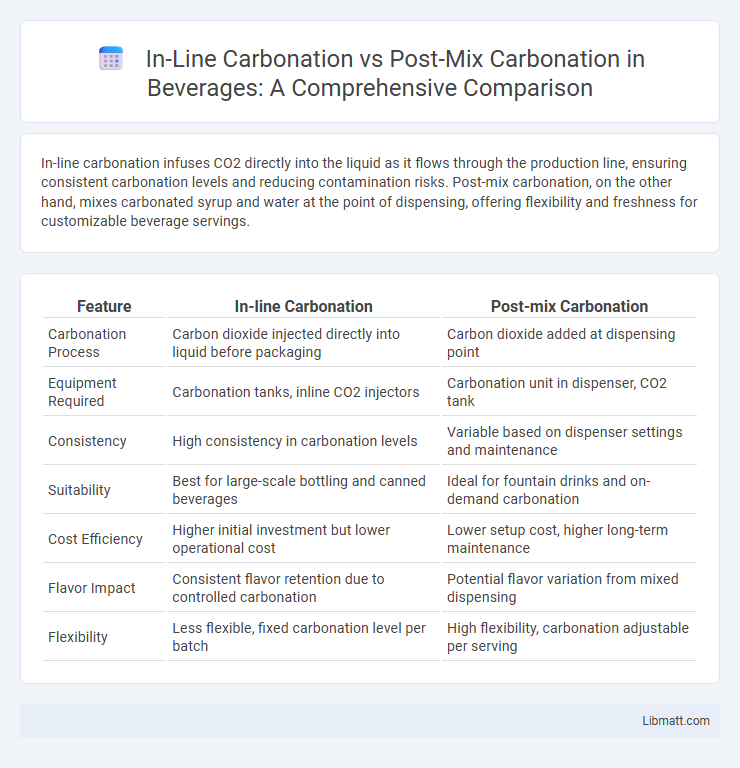

In-line carbonation infuses CO2 directly into the liquid as it flows through the production line, ensuring consistent carbonation levels and reducing contamination risks. Post-mix carbonation, on the other hand, mixes carbonated syrup and water at the point of dispensing, offering flexibility and freshness for customizable beverage servings.

Table of Comparison

| Feature | In-line Carbonation | Post-mix Carbonation |

|---|---|---|

| Carbonation Process | Carbon dioxide injected directly into liquid before packaging | Carbon dioxide added at dispensing point |

| Equipment Required | Carbonation tanks, inline CO2 injectors | Carbonation unit in dispenser, CO2 tank |

| Consistency | High consistency in carbonation levels | Variable based on dispenser settings and maintenance |

| Suitability | Best for large-scale bottling and canned beverages | Ideal for fountain drinks and on-demand carbonation |

| Cost Efficiency | Higher initial investment but lower operational cost | Lower setup cost, higher long-term maintenance |

| Flavor Impact | Consistent flavor retention due to controlled carbonation | Potential flavor variation from mixed dispensing |

| Flexibility | Less flexible, fixed carbonation level per batch | High flexibility, carbonation adjustable per serving |

Introduction to Carbonation Methods

In-line carbonation integrates carbon dioxide directly into the beverage during production, ensuring consistent gas dissolution and improved flavor profile. Post-mix carbonation involves adding CO2 at the dispensing point, commonly used in fountain drink systems, allowing for flexible mixing and carbonation levels. Both methods impact carbonation efficiency, taste retention, and equipment requirements in beverage production.

What is In-line Carbonation?

In-line carbonation is a process where carbon dioxide is injected directly into the beverage during the production line, allowing precise control over the carbonation level. This method ensures consistent carbonation quality by mixing CO2 with the liquid just before packaging, which maintains freshness and effervescence. Understanding in-line carbonation helps you choose the best system for producing sparkling beverages with optimal taste and texture.

What is Post-mix Carbonation?

Post-mix carbonation is a beverage dispensing method where carbonated water and syrup are mixed at the point of service, allowing for fresh, on-demand soda preparation. This process uses a dedicated carbonator to infuse CO2 into water before combining it with flavor concentrates, ensuring efficient storage and reduced space requirements. Understanding post-mix carbonation helps you optimize beverage quality and cost-effectiveness in commercial settings.

Key Differences Between In-line and Post-mix Carbonation

In-line carbonation integrates CO2 directly into the beverage during production, ensuring consistent carbonation levels and faster processing times, commonly used in large-scale bottling plants. Post-mix carbonation adds CO2 after mixing the syrup and water, allowing customization of carbonation levels for on-demand dispensing, typical in fountain drink systems. In-line carbonation offers greater control over carbonation uniformity, while post-mix carbonation provides flexibility and cost-effectiveness for restaurants and convenience stores.

Equipment and Setup Requirements

In-line carbonation systems require integrated equipment within the beverage production line to infuse CO2 directly during the mixing process, ensuring precise control and consistency. Post-mix carbonation involves separate carbonation units and storage tanks where CO2 is added after mixing, demanding more space and additional equipment for cooling and dispensing. Your choice depends on production scale and facility layout, as in-line setups offer compact operation, while post-mix systems provide flexibility for diverse beverage customization.

Carbonation Control and Consistency

In-line carbonation offers precise control over CO2 levels by continuously monitoring and adjusting gas infusion throughout the beverage production process, ensuring consistent carbonation in every batch. Post-mix carbonation relies on mixing syrup and carbonated water at the point of dispensing, which can lead to variability in carbonation levels due to fluctuations in temperature and pressure. Your choice between these systems will impact the uniformity of carbonation and the overall quality of your final product.

Impact on Beverage Taste and Quality

In-line carbonation integrates CO2 directly into the beverage during production, resulting in consistent carbonation levels and a fresher taste, preserving the original flavor profile. Post-mix carbonation adds CO2 at the dispensing point, which can cause variation in carbonation and potentially dilute flavor due to water mixing, impacting beverage quality. Your choice between these methods influences the balance of carbonation and taste, affecting overall consumer satisfaction.

Efficiency and Production Speed

In-line carbonation integrates CO2 directly into the beverage during production, significantly enhancing efficiency by reducing wait times and minimizing product handling. Post-mix carbonation, which carbonates water separately before mixing with syrup, tends to slow production speed due to additional steps and potential inconsistencies. Your operation benefits from in-line carbonation's streamlined process, leading to faster throughput and optimized resource use.

Cost Considerations

In-line carbonation typically incurs higher initial costs due to specialized equipment and integration requirements, but offers operational savings through precise CO2 control and reduced wastage. Post-mix carbonation systems have lower upfront expenses and simpler installation, making them ideal for small to medium-scale operations with moderate beverage demand. Long-term cost efficiency depends on production volume, with in-line systems proving more economical in high-volume environments due to improved energy efficiency and consistent carbonation levels.

Choosing the Best Carbonation Method for Your Needs

In-line carbonation delivers CO2 directly into the beverage during the mixing process, ensuring precise carbonation levels and consistent flavor, ideal for large-scale or continuous production environments. Post-mix carbonation injects CO2 after the beverage is mixed, offering flexibility and ease of adjustment for smaller batches or customizable drink options. Evaluating factors such as production volume, equipment costs, and desired carbonation control helps determine the optimal carbonation method to meet specific operational needs.

In-line carbonation vs post-mix carbonation Infographic

libmatt.com

libmatt.com