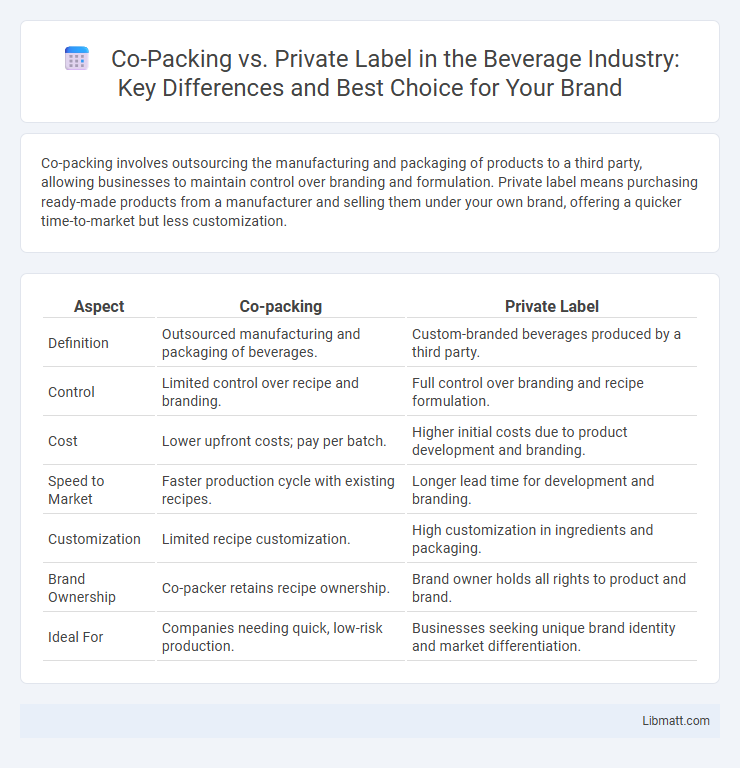

Co-packing involves outsourcing the manufacturing and packaging of products to a third party, allowing businesses to maintain control over branding and formulation. Private label means purchasing ready-made products from a manufacturer and selling them under your own brand, offering a quicker time-to-market but less customization.

Table of Comparison

| Aspect | Co-packing | Private Label |

|---|---|---|

| Definition | Outsourced manufacturing and packaging of beverages. | Custom-branded beverages produced by a third party. |

| Control | Limited control over recipe and branding. | Full control over branding and recipe formulation. |

| Cost | Lower upfront costs; pay per batch. | Higher initial costs due to product development and branding. |

| Speed to Market | Faster production cycle with existing recipes. | Longer lead time for development and branding. |

| Customization | Limited recipe customization. | High customization in ingredients and packaging. |

| Brand Ownership | Co-packer retains recipe ownership. | Brand owner holds all rights to product and brand. |

| Ideal For | Companies needing quick, low-risk production. | Businesses seeking unique brand identity and market differentiation. |

Introduction to Co-packing and Private Label

Co-packing involves outsourcing the packaging and sometimes production of products to a specialized company, enabling brands to scale operations efficiently without investing in manufacturing facilities. Private label refers to products manufactured by one company and sold under another company's brand name, allowing retailers to offer exclusive products without developing their own manufacturing processes. Both strategies help businesses expand product lines while reducing overhead and production complexities.

Definitions: Co-packing vs Private Label

Co-packing involves hiring a third-party manufacturer to produce and package products according to a company's specifications, allowing brands to outsource production while maintaining control over product design and marketing. Private label refers to products manufactured by a third party but branded and sold under a retailer's or company's own name, often using pre-existing product formulas or designs. Both strategies enable businesses to expand product lines without investing heavily in production facilities, but co-packing typically offers more customization compared to private label products.

Key Differences Between Co-packing and Private Label

Co-packing involves outsourcing the manufacturing and packaging of products to a third-party company, allowing you to maintain your own brand identity while leveraging specialized production capabilities. Private labeling means selling products made by another manufacturer under your own brand, often with no involvement in product formulation or manufacturing processes. The key differences lie in control over product customization, manufacturing responsibility, and brand ownership.

Benefits of Co-packing for Brands

Co-packing offers brands the advantage of leveraging specialized manufacturing expertise and scalable production without investing in costly equipment or facilities. It streamlines supply chain management, allowing you to focus on marketing and product development while ensuring consistent quality and faster time-to-market. This approach reduces operational risks and enhances flexibility, making it an ideal solution for emerging and established brands seeking efficient growth.

Advantages of Private Label Manufacturing

Private label manufacturing offers brands full control over product design, packaging, and branding, enabling tailored marketing strategies and stronger brand identity. It typically reduces production costs through economies of scale and eliminates the need for in-house manufacturing facilities, enhancing operational efficiency. Exclusive product offerings through private label manufacturing also foster customer loyalty and higher profit margins by differentiating from competitors.

Cost Considerations: Co-packing vs Private Label

Co-packing typically involves lower upfront costs as manufacturers handle production, packaging, and quality control, reducing the need for investment in equipment and facilities. Private label requires higher initial expenses due to product development, branding, and inventory management, but offers greater control over product customization and brand identity. Evaluating cost considerations between co-packing and private label depends on factors like order volume, product complexity, and long-term business goals.

Flexibility and Customization Options

Co-packing offers greater flexibility in production volume and packaging styles, allowing your brand to adjust quickly to market demands and seasonal changes. Private label provides customization primarily through product formulation and branding but may have more rigid minimum order quantities and packaging choices. Understanding these differences helps you select the best option to tailor your products efficiently without compromising on quality or speed.

Quality Control and Product Consistency

Co-packing companies implement rigorous quality control measures to ensure product consistency across large production runs, utilizing standardized processes and certified equipment. Private label manufacturing offers you tailored oversight, often allowing direct input into ingredient sourcing and production protocols to meet specific brand standards. Both approaches prioritize maintaining product integrity, but co-packing typically ensures scalability with uniform quality, while private label focuses on customizable control for unique formulations.

Choosing the Right Model for Your Business

Choosing between co-packing and private label depends on your business goals, budget, and control preferences. Co-packing allows you to leverage an existing manufacturer's expertise and equipment, reducing upfront costs and speeding time-to-market, while private labeling offers more branding flexibility but requires deeper involvement in product development and inventory management. Evaluate your production capacity, branding needs, and scalability plans to determine the most effective model for your business growth.

Conclusion: Which Option Suits Your Growth Strategy?

Choosing between co-packing and private label depends on your business goals and growth strategy. Co-packing offers scalability and reduced production complexity by leveraging established manufacturers, ideal for startups seeking speed to market. Private label provides greater brand control and differentiation, making it suitable for businesses aiming to build long-term brand equity and customer loyalty.

Co-packing vs private label Infographic

libmatt.com

libmatt.com