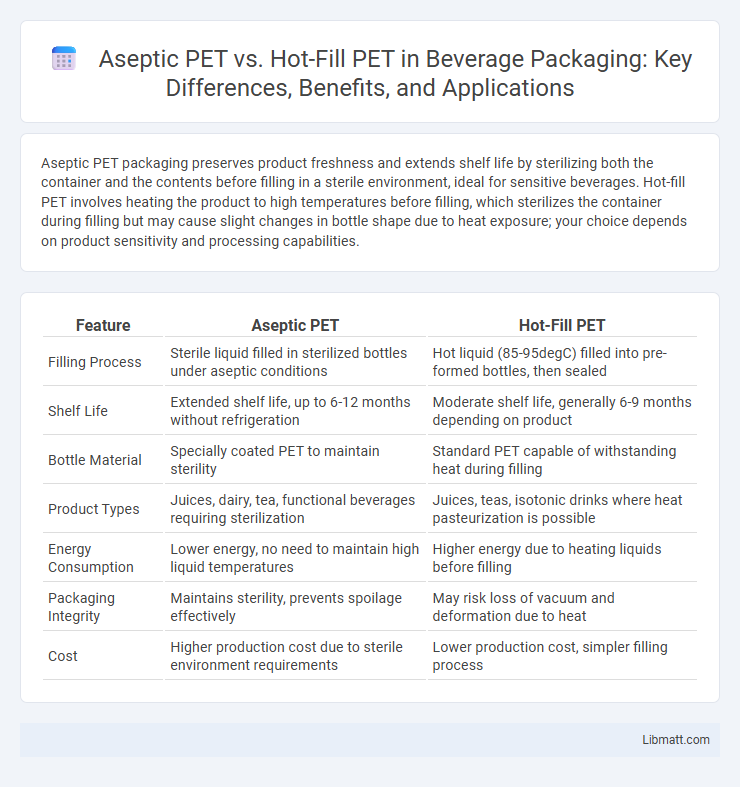

Aseptic PET packaging preserves product freshness and extends shelf life by sterilizing both the container and the contents before filling in a sterile environment, ideal for sensitive beverages. Hot-fill PET involves heating the product to high temperatures before filling, which sterilizes the container during filling but may cause slight changes in bottle shape due to heat exposure; your choice depends on product sensitivity and processing capabilities.

Table of Comparison

| Feature | Aseptic PET | Hot-Fill PET |

|---|---|---|

| Filling Process | Sterile liquid filled in sterilized bottles under aseptic conditions | Hot liquid (85-95degC) filled into pre-formed bottles, then sealed |

| Shelf Life | Extended shelf life, up to 6-12 months without refrigeration | Moderate shelf life, generally 6-9 months depending on product |

| Bottle Material | Specially coated PET to maintain sterility | Standard PET capable of withstanding heat during filling |

| Product Types | Juices, dairy, tea, functional beverages requiring sterilization | Juices, teas, isotonic drinks where heat pasteurization is possible |

| Energy Consumption | Lower energy, no need to maintain high liquid temperatures | Higher energy due to heating liquids before filling |

| Packaging Integrity | Maintains sterility, prevents spoilage effectively | May risk loss of vacuum and deformation due to heat |

| Cost | Higher production cost due to sterile environment requirements | Lower production cost, simpler filling process |

Introduction to PET Packaging Technologies

Aseptic PET packaging technology uses sterilized containers and fillers to maintain product sterility, preserving the freshness of beverages without refrigeration and extending shelf life significantly. Hot-fill PET involves filling containers with liquid at high temperatures, typically above 85degC, to eliminate microbial contamination, but requires special PET grades to withstand thermal stress and prevent deformation. Your choice between aseptic and hot-fill PET depends on the specific product requirements, shelf life expectations, and processing capabilities.

What is Aseptic PET?

Aseptic PET is a packaging technology that sterilizes both the PET container and the product separately before filling, ensuring extended shelf life without preservatives or refrigeration. This process maintains product freshness and safety by preventing microbial contamination through a controlled sterile environment. You benefit from Aseptic PET packaging when storing beverages or sensitive liquids that require long-term preservation without compromising quality.

What is Hot-Fill PET?

Hot-Fill PET is a type of polyethylene terephthalate bottle designed to withstand high temperatures during the filling process, typically around 85-95degC, making it ideal for products like juices, teas, and sauces that require pasteurization to ensure safety and shelf stability. Unlike Aseptic PET, which involves sterilizing both the container and the product separately before filling in a sterile environment, hot-fill PET bottles are filled immediately after heating, relying on the heat to sterilize the container's interior. Understanding this difference helps you choose the appropriate packaging method based on your product's thermal and sterility requirements.

Key Differences Between Aseptic PET and Hot-Fill PET

Aseptic PET bottles are sterilized separately before filling in a sterile environment, allowing them to package heat-sensitive products without compromising quality, while hot-fill PET bottles are heated during the filling process to temperatures typically between 85degC and 95degC to kill microbes inside the container. Aseptic PET requires advanced sterilization equipment and is suitable for long shelf-life products such as juices and dairy, whereas hot-fill PET is simpler and ideal for acidic products that can withstand high temperatures like fruit juices and teas. Material properties and design of hot-fill PET bottles are optimized to withstand thermal deformation, while aseptic PET bottles focus more on maintaining sterility without the need for heat resistance.

Benefits of Aseptic PET Packaging

Aseptic PET packaging offers extended shelf life without the need for preservatives or refrigeration, preserving the freshness and nutritional quality of beverages. This method reduces energy consumption by eliminating the hot-fill process, leading to lower production costs and a smaller carbon footprint. Your products benefit from enhanced safety and clarity, maintaining high quality while meeting stringent food safety standards.

Advantages of Hot-Fill PET Packaging

Hot-fill PET packaging offers superior microbial safety by undergoing high-temperature filling that effectively sterilizes the product and extends shelf life without preservatives. It maintains product quality by preventing contamination and preserving taste and nutrient value, ideal for juices, teas, and sauces. Your products benefit from enhanced durability and a lightweight design, reducing transportation costs and environmental impact.

Product Suitability: Aseptic PET vs Hot-Fill PET

Aseptic PET packaging is ideal for heat-sensitive products such as dairy, juices, and liquid eggs, as it enables extended shelf life without preservatives by sterilizing both the product and the container separately before filling. Hot-fill PET, suitable for products like juices, teas, and sauces, involves filling the container with a hot liquid (above 85degC) to sterilize the package and product simultaneously but requires specially designed PET bottles to withstand high temperatures and prevent deformation. While aseptic PET offers superior product protection and shelf stability for delicate items, hot-fill PET provides a cost-effective solution for maintaining safety and freshness in beverages with inherent heat resistance.

Cost Implications and Efficiency Analysis

Aseptic PET packaging typically incurs higher upfront costs due to advanced sterilization equipment and stricter contamination controls, while hot-fill PET offers lower initial investment but may lead to increased energy consumption for maintaining temperature. Efficiency analysis shows aseptic PET enables extended shelf life without preservatives, reducing waste and distribution frequency, whereas hot-fill PET is faster for high-throughput lines but limits product variety due to heat sensitivity. Your choice depends on balancing cost constraints with desired product longevity and operational throughput requirements.

Sustainability and Environmental Impact

Aseptic PET packaging uses advanced sterilization techniques that allow products to be stored without refrigeration, reducing energy consumption and lowering carbon emissions compared to traditional hot-fill PET, which requires heating the contents and containers. Hot-fill PET typically demands more energy during the filling process, leading to a higher environmental footprint, while aseptic PET's ability to preserve beverages without preservatives or refrigeration aligns with sustainability goals. Choosing aseptic PET can help reduce your overall environmental impact through decreased energy use and extended product shelf life.

Future Trends in PET Packaging Technologies

Future trends in PET packaging technologies highlight the growth of aseptic PET as it offers extended shelf life without preservatives, meeting consumer demand for natural products. Innovations in barrier coatings and multilayer PET structures enhance both aseptic and hot-fill PET performance against oxygen and moisture ingress. Sustainability efforts drive research into bio-based PET and improved recyclability, making aseptic and hot-fill PET packaging more environmentally friendly in the packaging market.

Aseptic PET vs hot-fill PET Infographic

libmatt.com

libmatt.com