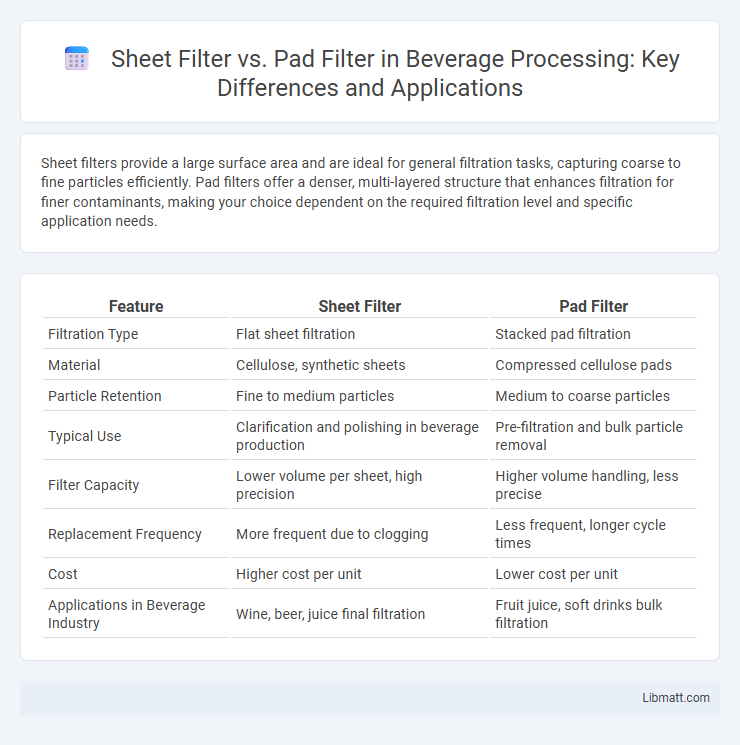

Sheet filters provide a large surface area and are ideal for general filtration tasks, capturing coarse to fine particles efficiently. Pad filters offer a denser, multi-layered structure that enhances filtration for finer contaminants, making your choice dependent on the required filtration level and specific application needs.

Table of Comparison

| Feature | Sheet Filter | Pad Filter |

|---|---|---|

| Filtration Type | Flat sheet filtration | Stacked pad filtration |

| Material | Cellulose, synthetic sheets | Compressed cellulose pads |

| Particle Retention | Fine to medium particles | Medium to coarse particles |

| Typical Use | Clarification and polishing in beverage production | Pre-filtration and bulk particle removal |

| Filter Capacity | Lower volume per sheet, high precision | Higher volume handling, less precise |

| Replacement Frequency | More frequent due to clogging | Less frequent, longer cycle times |

| Cost | Higher cost per unit | Lower cost per unit |

| Applications in Beverage Industry | Wine, beer, juice final filtration | Fruit juice, soft drinks bulk filtration |

Introduction to Sheet Filters and Pad Filters

Sheet filters use flat, pleated media to remove particulates from air or liquids, offering high filtration efficiency and easy replacement. Pad filters consist of fibrous mat layers designed to trap larger debris and contaminants, commonly utilized in HVAC systems for pre-filtration. Both filter types serve distinct roles in air and liquid purification, balancing airflow resistance and filtration depth.

How Sheet Filters Work

Sheet filters operate by passing fluid through a thin, porous membrane or fabric that traps solid particles on its surface. The filtration mechanism relies on particle size exclusion and surface retention, allowing clean fluid to pass while contaminants accumulate on the sheet. This design ensures high-efficiency separation suitable for applications requiring precise particle removal.

How Pad Filters Function

Pad filters function by trapping airborne particles as air passes through a dense mat of fibrous material, which captures dust, dirt, and allergens effectively. These filters rely on mechanical entrapment rather than electrostatic charge, making them durable and consistent in performance for HVAC systems. Your choice of pad filter ensures efficient air purification while maintaining optimal airflow and reducing strain on your system.

Key Differences Between Sheet and Pad Filters

Sheet filters consist of continuous sheets of filtering media that capture particles through surface filtration, whereas pad filters are thicker, multi-layered and designed for depth filtration by trapping contaminants within the media. Sheet filters offer easier maintenance and typically higher airflow efficiency, while pad filters provide enhanced dust-holding capacity and longer service intervals. Your choice between sheet and pad filters depends on the specific filtration needs, such as airflow requirements and particle load.

Filtration Efficiency: Sheet vs Pad Filters

Sheet filters offer higher filtration efficiency by providing a uniform surface area that captures smaller particles consistently, making them ideal for fine dust and airborne contaminants. Pad filters, while more economical, typically have lower efficiency due to their thicker, less uniform media that allows more particulates to pass through. The choice between sheet and pad filters depends on the required air quality standards, with sheet filters preferred in applications demanding superior contaminant removal.

Applications and Best Uses for Each Filter Type

Sheet filters excel in applications requiring high flow rates and efficient removal of large particles, making them ideal for water treatment, chemical processing, and food and beverage production. Pad filters are best suited for fine filtration needs in HVAC systems, paint booths, and pharmaceutical manufacturing, where capturing smaller contaminants and maintaining airflow are critical. Understanding your specific filtration requirements ensures you select the right filter type to optimize performance and longevity.

Maintenance and Operating Costs Comparison

Sheet filters generally require less frequent replacement but involve higher manual cleaning efforts, leading to moderate maintenance costs over time. Pad filters typically have lower upfront costs but need regular disposal and replacement, increasing operating expenses in high-use environments. The choice between sheet and pad filters impacts long-term expenses, with sheet filters favoring durability and pad filters emphasizing convenience.

Advantages of Sheet Filters

Sheet filters offer superior filtration efficiency due to their larger surface area, which captures more particles while maintaining higher flow rates. These filters provide greater durability and ease of maintenance compared to pad filters, reducing operational downtime and replacement costs. Their modular design allows for customization to various industrial applications, enhancing overall filtering performance.

Benefits of Pad Filters

Pad filters offer superior air filtration by effectively capturing larger dust particles, pet dander, and pollen, enhancing indoor air quality. Their dense, fibrous material promotes longer filter life and reduces the frequency of replacements, leading to cost savings. These filters also improve HVAC system efficiency by protecting internal components from debris buildup, ensuring optimal performance.

Choosing the Right Filter for Your Needs

Sheet filters excel in applications requiring high filtration efficiency and large surface area, ideal for fine particle removal in industrial processes. Pad filters offer cost-effective, disposable solutions suited for lower filtration demands and easy maintenance in residential HVAC systems. Selecting the right filter hinges on balancing filtration efficiency, budget constraints, and maintenance frequency to meet specific operational requirements.

Sheet filter vs pad filter Infographic

libmatt.com

libmatt.com