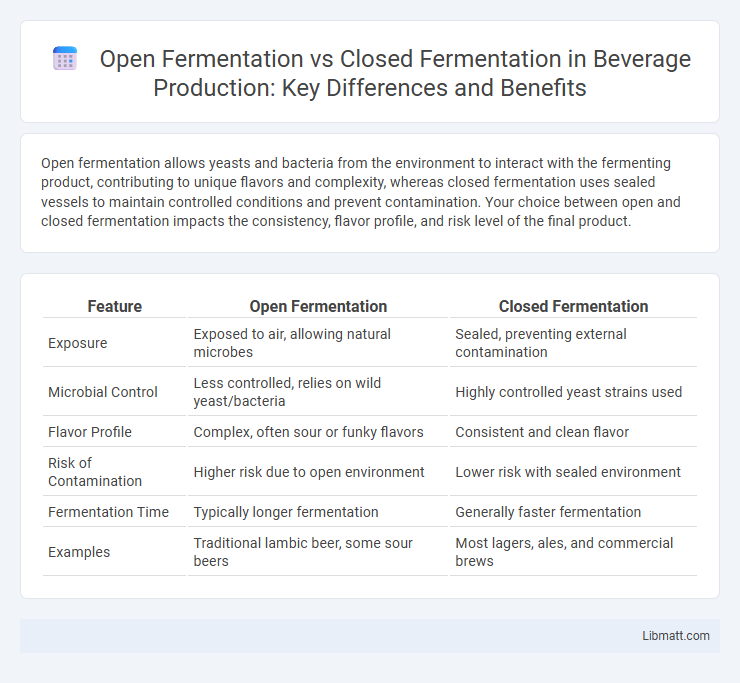

Open fermentation allows yeasts and bacteria from the environment to interact with the fermenting product, contributing to unique flavors and complexity, whereas closed fermentation uses sealed vessels to maintain controlled conditions and prevent contamination. Your choice between open and closed fermentation impacts the consistency, flavor profile, and risk level of the final product.

Table of Comparison

| Feature | Open Fermentation | Closed Fermentation |

|---|---|---|

| Exposure | Exposed to air, allowing natural microbes | Sealed, preventing external contamination |

| Microbial Control | Less controlled, relies on wild yeast/bacteria | Highly controlled yeast strains used |

| Flavor Profile | Complex, often sour or funky flavors | Consistent and clean flavor |

| Risk of Contamination | Higher risk due to open environment | Lower risk with sealed environment |

| Fermentation Time | Typically longer fermentation | Generally faster fermentation |

| Examples | Traditional lambic beer, some sour beers | Most lagers, ales, and commercial brews |

Introduction to Fermentation Processes

Open fermentation involves exposing the fermenting substrate to the external environment, allowing natural yeast and bacteria to initiate fermentation, commonly used in traditional brewing and sourdough production. Closed fermentation employs sealed vessels that limit contamination and control oxygen levels, optimizing the growth of specific microbes for consistent product quality, prevalent in modern beer and wine production. Key differences revolve around microbial exposure, oxygen management, and contamination risk, which significantly influence flavor profile, fermentation speed, and scalability.

Defining Open Fermentation

Open fermentation refers to a traditional brewing process where the fermenting vessel is exposed to the surrounding environment, allowing natural yeast and bacteria to interact with the brew. This method often results in unique flavor profiles due to wild microbial activity and is commonly used in sour beer or lambic production. Unlike closed fermentation, open fermentation requires careful environmental control to prevent contamination while encouraging beneficial microbial presence.

Understanding Closed Fermentation

Closed fermentation involves fermenting liquids in sealed containers, preventing exposure to oxygen and contaminants, which ensures a controlled and consistent process. This method enhances product purity and allows precise regulation of temperature and pressure, leading to improved flavor profiles and reduced risk of spoilage. Understanding closed fermentation helps you optimize brewing or winemaking by maximizing quality and minimizing external influences.

Key Differences Between Open and Closed Fermentation

Open fermentation exposes the brew to the external environment, allowing wild yeast and bacteria to influence the fermentation process, which can introduce unique flavors but also increases the risk of contamination. Closed fermentation occurs in sealed vessels, maintaining a controlled atmosphere that limits oxygen exposure and microbial invasion, resulting in more consistent and predictable flavor profiles. The choice between open and closed fermentation impacts factors such as fermentation time, flavor complexity, microbial diversity, and the level of sanitation required.

Microbial Influence in Open vs Closed Systems

Open fermentation allows diverse environmental microbes to influence the microbial community, promoting spontaneous fermentation and unique flavor profiles through wild yeast and bacteria. Closed fermentation systems maintain controlled, sterile conditions that limit microbial variability, ensuring consistent yeast strains dominate and produce predictable, high-quality results. The microbial influence in open systems fosters complex biochemical interactions, while closed systems prioritize sanitary conditions and microbial stability.

Equipment and Setup Requirements

Open fermentation requires simple, open vessels like wooden vats or stainless steel tubs with minimal sealing, allowing exposure to ambient air and natural microbial flora. Closed fermentation involves sealed, pressurized tanks made from stainless steel or glass equipped with airlocks or valves to control gas exchange and maintain sterile conditions. Your choice of fermentation setup impacts not only equipment costs but also contamination risk and process control.

Advantages of Open Fermentation

Open fermentation offers advantages such as enhanced microbial diversity and improved flavor complexity due to natural yeast and bacteria exposure. It allows for easier monitoring and correction during the fermentation process, promoting artisanal and unique product characteristics. The method also tends to be more cost-effective by reducing the need for expensive sealed equipment and strict sterilization.

Benefits of Closed Fermentation

Closed fermentation offers enhanced control over temperature, contamination risks, and oxygen exposure, leading to consistent product quality and safety. This method minimizes the chance of unwanted microbial growth, ensuring a cleaner fermentation process and improved flavor profile. You benefit from reduced product loss and easier monitoring, making it ideal for large-scale or precise fermentation operations.

Quality Control and Contamination Risks

Closed fermentation offers superior quality control by maintaining a sterile, oxygen-limited environment, minimizing contamination risks from wild yeast and bacteria. Open fermentation exposes the process to ambient air, increasing the likelihood of microbial contamination, which can lead to inconsistent flavor profiles and spoilage. Effective sanitation protocols and environmental monitoring are essential to manage contamination in open systems, while closed systems rely on airtight vessels and controlled parameters for consistent product quality.

Choosing the Right Fermentation Method

Choosing the right fermentation method depends on factors such as product type, contamination risk, and desired flavor profile. Open fermentation offers enhanced oxygen exposure, benefiting certain yeast strains and traditional beer styles, while closed fermentation provides a sterile environment that minimizes contamination and allows precise control of pressure and temperature. Industrial breweries often prefer closed fermentation for consistency and efficiency, whereas artisanal producers may select open fermentation to achieve unique, complex flavors.

Open fermentation vs closed fermentation Infographic

libmatt.com

libmatt.com