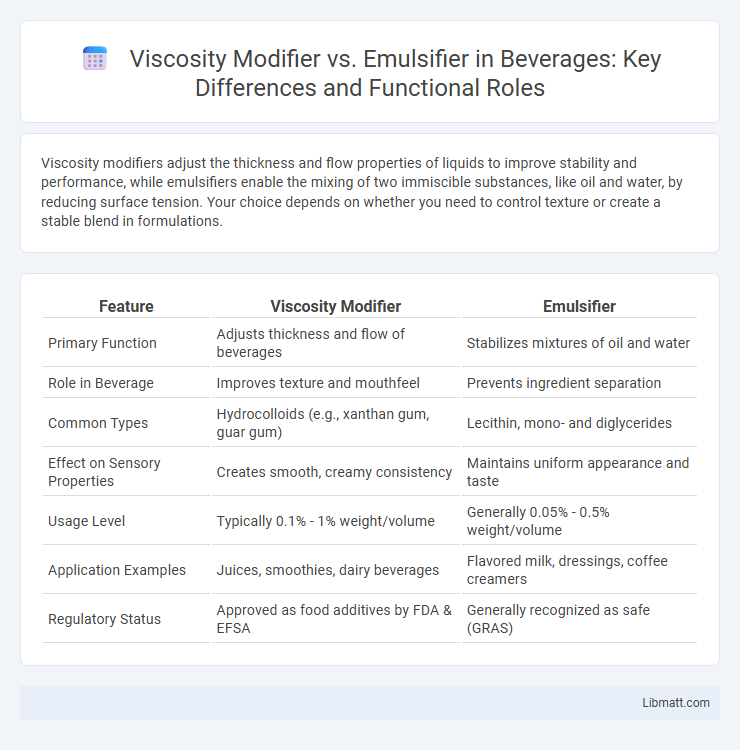

Viscosity modifiers adjust the thickness and flow properties of liquids to improve stability and performance, while emulsifiers enable the mixing of two immiscible substances, like oil and water, by reducing surface tension. Your choice depends on whether you need to control texture or create a stable blend in formulations.

Table of Comparison

| Feature | Viscosity Modifier | Emulsifier |

|---|---|---|

| Primary Function | Adjusts thickness and flow of beverages | Stabilizes mixtures of oil and water |

| Role in Beverage | Improves texture and mouthfeel | Prevents ingredient separation |

| Common Types | Hydrocolloids (e.g., xanthan gum, guar gum) | Lecithin, mono- and diglycerides |

| Effect on Sensory Properties | Creates smooth, creamy consistency | Maintains uniform appearance and taste |

| Usage Level | Typically 0.1% - 1% weight/volume | Generally 0.05% - 0.5% weight/volume |

| Application Examples | Juices, smoothies, dairy beverages | Flavored milk, dressings, coffee creamers |

| Regulatory Status | Approved as food additives by FDA & EFSA | Generally recognized as safe (GRAS) |

Understanding Viscosity Modifiers and Emulsifiers

Viscosity modifiers regulate the thickness and flow of liquids, ensuring consistent texture and stability in products such as lubricants and paints. Emulsifiers stabilize mixtures of immiscible liquids like oil and water by reducing surface tension and preventing separation, crucial in cosmetics and food industries. Understanding the distinct roles of viscosity modifiers and emulsifiers helps you select the right additive to optimize product performance and durability.

Defining Viscosity Modifiers: Function and Applications

Viscosity modifiers are specialized additives used to control the flow properties of liquids by increasing or stabilizing their viscosity under varying conditions, enhancing product performance in lubricants, paints, and cosmetics. These modifiers improve shear stability and temperature resistance, ensuring consistent thickness and smooth application across different environments. Your formulations benefit from viscosity modifiers by maintaining ideal texture and flow behavior, distinguishing them from emulsifiers that primarily focus on stabilizing mixtures of immiscible liquids.

What Are Emulsifiers? Key Functions in Formulations

Emulsifiers are amphiphilic molecules that stabilize mixtures of immiscible liquids like oil and water by reducing interfacial tension, essential for creating uniform and stable emulsions in cosmetic, food, and pharmaceutical formulations. They enable consistent texture, improve product stability, and enhance the delivery of active ingredients by maintaining homogeneity throughout the product's shelf life. Unlike viscosity modifiers, which primarily adjust flow properties, emulsifiers play a critical role in combining and maintaining disparate components in a single phase.

Chemical Mechanisms: How Viscosity Modifiers Work

Viscosity modifiers function by altering the flow behavior of fluids through molecular interactions that increase resistance to shear, often involving long-chain polymers that entangle or expand in response to stress. In contrast, emulsifiers stabilize mixtures of immiscible liquids by reducing interfacial tension and forming protective layers around droplets, preventing coalescence rather than directly affecting fluid viscosity. Understanding how viscosity modifiers work chemically can help you select the right additive to control texture and flow properties in formulations effectively.

Mechanism of Action: Emulsifiers in Mixtures

Emulsifiers stabilize mixtures by reducing interfacial tension between immiscible liquids, allowing uniform dispersion of one phase within the other. They contain amphiphilic molecules that orient at the interface, forming a protective barrier to prevent droplet coalescence and promote emulsion stability. Unlike viscosity modifiers that primarily adjust flow properties, emulsifiers actively maintain phase distribution through molecular interactions at the interface.

Common Industries Using Viscosity Modifiers

Viscosity modifiers are crucial in industries such as automotive lubricants, paints and coatings, and adhesives, where they enhance fluid stability and performance under varying temperature conditions. Emulsifiers, by contrast, find primary application in food processing, pharmaceuticals, and cosmetics to maintain homogeneous mixtures of immiscible liquids. The automotive industry prominently relies on viscosity modifiers to ensure engine oil remains effective across a wide temperature range, improving fuel efficiency and reducing mechanical wear.

Typical Applications of Emulsifiers Across Sectors

Emulsifiers play a critical role in sectors such as food, cosmetics, pharmaceuticals, and industrial formulations by stabilizing mixtures of oil and water to create uniform products like salad dressings, creams, and ointments. Unlike viscosity modifiers that primarily alter fluid thickness, emulsifiers ensure consistent texture and improved shelf life in your products by preventing separation. Their typical applications extend to enhancing product stability, texture, and appearance, crucial for consumer satisfaction and manufacturing efficiency.

Key Differences Between Viscosity Modifiers and Emulsifiers

Viscosity modifiers primarily adjust the thickness and flow characteristics of liquids, ensuring consistent texture and stability in products like lubricants and paints. Emulsifiers, on the other hand, facilitate the mixing of immiscible liquids such as oil and water, creating stable emulsions essential in food, cosmetics, and pharmaceuticals. Your choice between these additives depends on whether you need to control fluid flow or maintain a uniform mixture.

Selection Criteria: Choosing Between Viscosity Modifier vs Emulsifier

Selection criteria between viscosity modifiers and emulsifiers depend on the desired texture and stability of the formulation. Viscosity modifiers are chosen to adjust flow properties and enhance the thickness without affecting phase compatibility, while emulsifiers are selected to stabilize mixtures of immiscible liquids by reducing interfacial tension. Key factors include the type of base formulation, compatibility with active ingredients, and the required physical and chemical stability for the intended application.

Future Trends in Viscosity Modifiers and Emulsifiers

Future trends in viscosity modifiers emphasize the development of bio-based and sustainable polymers that enhance flow properties while reducing environmental impact. Emulsifiers are evolving towards multifunctional agents that improve stability and compatibility across diverse formulations, driven by demand for cleaner labels and innovative cosmetic and pharmaceutical products. Your choice of advanced viscosity modifiers and emulsifiers will leverage nanotechnology and green chemistry to achieve superior performance and eco-friendly profiles.

Viscosity modifier vs emulsifier Infographic

libmatt.com

libmatt.com