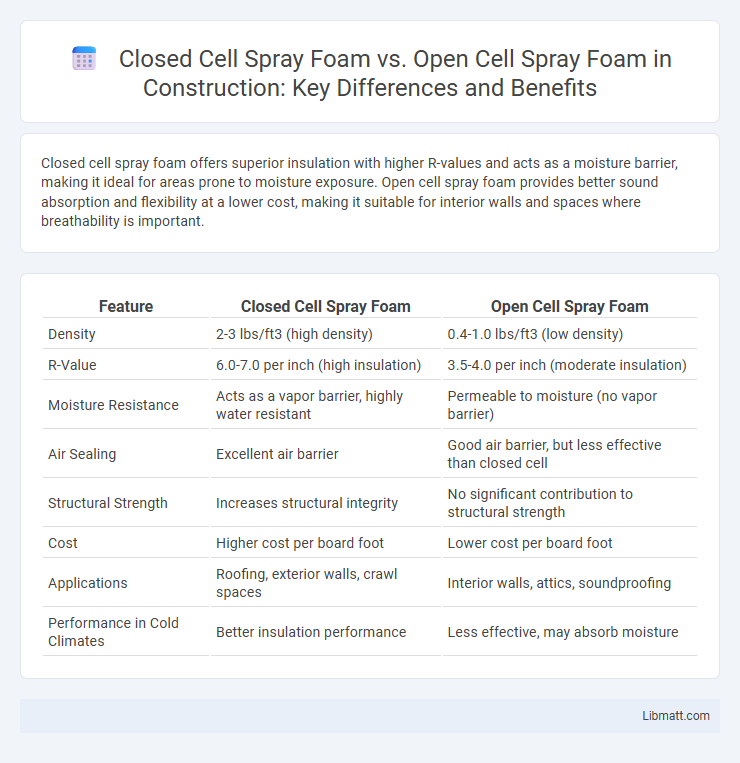

Closed cell spray foam offers superior insulation with higher R-values and acts as a moisture barrier, making it ideal for areas prone to moisture exposure. Open cell spray foam provides better sound absorption and flexibility at a lower cost, making it suitable for interior walls and spaces where breathability is important.

Table of Comparison

| Feature | Closed Cell Spray Foam | Open Cell Spray Foam |

|---|---|---|

| Density | 2-3 lbs/ft3 (high density) | 0.4-1.0 lbs/ft3 (low density) |

| R-Value | 6.0-7.0 per inch (high insulation) | 3.5-4.0 per inch (moderate insulation) |

| Moisture Resistance | Acts as a vapor barrier, highly water resistant | Permeable to moisture (no vapor barrier) |

| Air Sealing | Excellent air barrier | Good air barrier, but less effective than closed cell |

| Structural Strength | Increases structural integrity | No significant contribution to structural strength |

| Cost | Higher cost per board foot | Lower cost per board foot |

| Applications | Roofing, exterior walls, crawl spaces | Interior walls, attics, soundproofing |

| Performance in Cold Climates | Better insulation performance | Less effective, may absorb moisture |

Introduction to Spray Foam Insulation

Spray foam insulation, available in closed cell and open cell types, enhances energy efficiency by creating an effective air barrier and reducing heat transfer. Closed cell spray foam offers higher R-values per inch and superior moisture resistance, making it ideal for exterior walls and areas exposed to water. Open cell spray foam provides excellent sound absorption and flexibility, suitable for interior applications where breathability is desired.

What is Closed Cell Spray Foam?

Closed cell spray foam is a rigid, high-density insulation material composed of cells that are completely sealed and packed tightly together, providing superior thermal resistance with an R-value of approximately 6 to 7 per inch. This spray foam acts as both an insulation and an air barrier, making it ideal for moisture control and structural reinforcement in walls, roofs, and foundations. Its impermeability to air and water vapor makes it a preferred choice for applications requiring enhanced energy efficiency and protection against mold and mildew.

What is Open Cell Spray Foam?

Open cell spray foam is a lightweight, porous insulation material with a density typically between 0.4 to 0.5 pounds per cubic foot, allowing air to fill the cells, which enhances sound absorption and flexibility. It provides an R-value of approximately 3.5 to 3.6 per inch, making it effective for interior applications where vapor permeability and breathability are important. Open cell foam expands significantly upon application, filling gaps and cracks, but is less effective as a moisture barrier compared to closed cell spray foam.

Key Differences Between Closed Cell and Open Cell Spray Foam

Closed cell spray foam has a higher R-value per inch, typically around 6 to 7, providing superior insulation and acting as a moisture barrier, while open cell foam offers an R-value of about 3.5 per inch and allows vapor permeability. The dense structure of closed cell foam gives it greater structural strength and resistance to water, making it ideal for exterior applications and below-grade installations; open cell foam's softer, more flexible nature suits interior walls and soundproofing. Understanding these key differences helps you choose the right spray foam insulation for your project's thermal, moisture, and structural requirements.

Insulation Performance: R-Value Comparison

Closed cell spray foam offers a higher R-value per inch, typically around 6 to 7, providing superior insulation performance and moisture resistance compared to open cell spray foam, which has an R-value near 3.5 to 4 per inch. This means your space benefits from better thermal protection and energy efficiency with closed cell foam, especially in areas requiring a robust air and vapor barrier. Open cell foam's lower density and R-value make it suitable for interior applications where sound dampening is prioritized over maximum insulation.

Air and Moisture Barrier Capabilities

Closed cell spray foam provides superior air and moisture barrier capabilities due to its dense structure, effectively preventing air infiltration and water vapor transmission. Open cell spray foam, with its lower density and porous composition, offers less resistance to moisture and air, making it less effective as a vapor barrier. Buildings requiring high-performance insulation and moisture control typically benefit from the enhanced sealing properties of closed cell spray foam.

Soundproofing Effectiveness

Closed cell spray foam provides superior soundproofing effectiveness due to its higher density and rigid structure, which better blocks airborne noise and reduces sound transmission between rooms. Open cell spray foam, while offering some noise absorption thanks to its porous and flexible nature, is less effective at completely sealing sound gaps and minimizing impact noise. Choosing closed cell spray foam is ideal for applications requiring enhanced acoustic insulation and noise reduction.

Cost Analysis: Closed Cell vs Open Cell Spray Foam

Closed cell spray foam typically costs between $1.00 to $1.50 per board foot, while open cell spray foam ranges from $0.44 to $0.65 per board foot, making open cell more cost-effective for large-scale insulation projects. Installation expenses for closed cell foam are higher due to its denser composition and specialized equipment requirements, influencing overall budget decisions. Despite the higher initial investment, closed cell's superior R-value per inch (6 to 7) often results in better energy savings compared to open cell foam, which has an R-value around 3.5 per inch.

Best Applications for Closed Cell and Open Cell Spray Foam

Closed cell spray foam is ideal for areas requiring high insulation value, moisture resistance, and structural reinforcement, such as basements, roofs, and exterior walls. Open cell spray foam excels in interior spaces needing soundproofing and flexibility, like interior walls and attics, due to its softer, more breathable nature. Your choice depends on whether you prioritize durability and moisture barrier properties or cost-effective sound insulation and air sealing.

Choosing the Right Spray Foam Insulation for Your Project

Closed cell spray foam offers superior insulation with an R-value of approximately 6.5 per inch and provides a moisture barrier, making it ideal for areas prone to water exposure or high humidity. Open cell spray foam, with an R-value around 3.7 per inch, is more cost-effective and allows for better sound absorption, suitable for interior applications where moisture resistance is less critical. Selecting between closed and open cell spray foam depends on project requirements such as thermal performance, budget, and moisture control needs.

Closed cell spray foam vs open cell spray foam Infographic

libmatt.com

libmatt.com