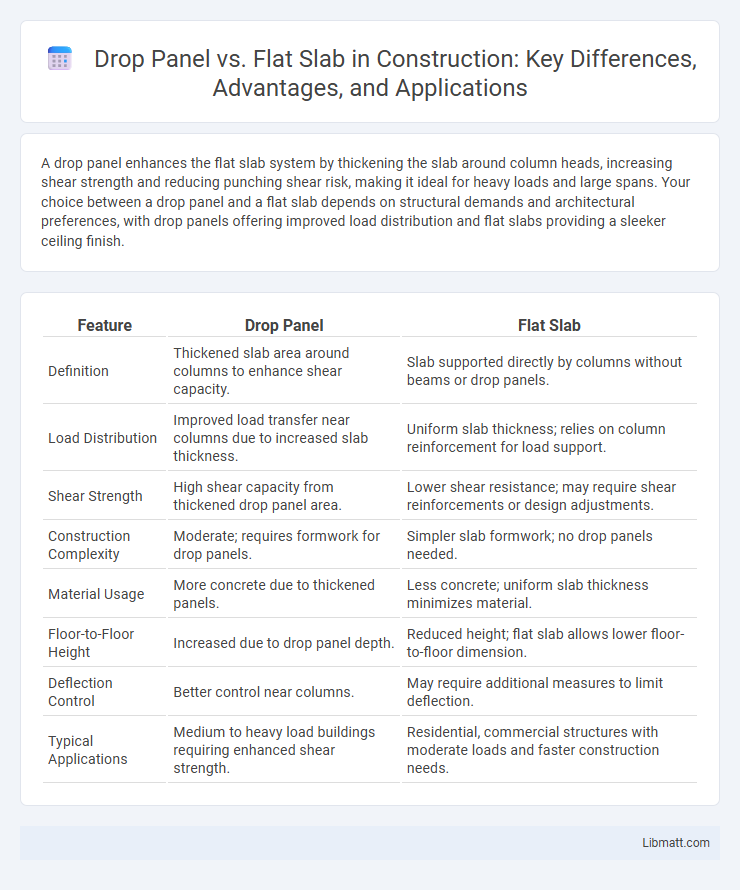

A drop panel enhances the flat slab system by thickening the slab around column heads, increasing shear strength and reducing punching shear risk, making it ideal for heavy loads and large spans. Your choice between a drop panel and a flat slab depends on structural demands and architectural preferences, with drop panels offering improved load distribution and flat slabs providing a sleeker ceiling finish.

Table of Comparison

| Feature | Drop Panel | Flat Slab |

|---|---|---|

| Definition | Thickened slab area around columns to enhance shear capacity. | Slab supported directly by columns without beams or drop panels. |

| Load Distribution | Improved load transfer near columns due to increased slab thickness. | Uniform slab thickness; relies on column reinforcement for load support. |

| Shear Strength | High shear capacity from thickened drop panel area. | Lower shear resistance; may require shear reinforcements or design adjustments. |

| Construction Complexity | Moderate; requires formwork for drop panels. | Simpler slab formwork; no drop panels needed. |

| Material Usage | More concrete due to thickened panels. | Less concrete; uniform slab thickness minimizes material. |

| Floor-to-Floor Height | Increased due to drop panel depth. | Reduced height; flat slab allows lower floor-to-floor dimension. |

| Deflection Control | Better control near columns. | May require additional measures to limit deflection. |

| Typical Applications | Medium to heavy load buildings requiring enhanced shear strength. | Residential, commercial structures with moderate loads and faster construction needs. |

Introduction to Drop Panels and Flat Slabs

Drop panels are thickened slab areas around columns designed to increase shear strength and reduce punching shear in reinforced concrete structures. Flat slabs are horizontal concrete slabs supported directly by columns, eliminating beams to create a flat ceiling surface and simplify formwork. Both systems improve load distribution but differ in structural detailing and construction efficiency.

Structural Overview of Flat Slabs

Flat slabs consist of a slab supported directly by columns without beams, providing uniform thickness and allowing easier formwork and faster construction. This structural system efficiently distributes loads through two-way bending, reducing slab depth and material usage compared to traditional beam-slab systems. Flat slabs enhance architectural flexibility by eliminating beam projections, creating smooth ceiling surfaces ideal for modern building designs.

Key Features of Drop Panel Slabs

Drop panel slabs feature thickened slab areas around column heads to enhance shear strength and reduce punching shear stress, improving load distribution and structural stability. These slabs also provide increased depth at critical points without significantly raising overall slab thickness, optimizing material usage for better cost efficiency. The design facilitates easier placement of mechanical and electrical systems due to the flat underside between drop panels, promoting architectural versatility.

Load Distribution Mechanisms

Drop panels enhance load distribution by increasing the slab thickness around columns, reducing shear stresses and improving punching resistance, which allows for greater load transfer efficiency at critical points. Flat slabs rely on uniform thickness and column capitals or heads for load dispersion, resulting in straightforward force paths but higher vulnerability to punching shear without reinforcement. The choice between drop panel and flat slab designs directly influences load distribution capabilities, structural stiffness, and overall performance under heavy loads.

Design Considerations and Criteria

Drop panels enhance slab-column connections by increasing shear capacity and reducing punching shear stress, making them suitable for heavy loads and large column spacing; flat slabs provide simplicity in formwork and faster construction but require careful design against punching shear with shear reinforcement or thicker slabs. Key design criteria for drop panels include panel thickness, width, and effective depth, optimizing load distribution and stiffness, while flat slabs must balance slab depth and reinforcement layout to control deflection and shear failure. Selecting between drop panels and flat slabs hinges on factors like structural load demands, architectural constraints, and cost-efficiency in material and labor.

Construction Techniques and Challenges

Drop panels in slab construction involve thickened slab areas around columns to enhance shear strength and reduce punching shear risk, requiring careful formwork and reinforcement detailing, which increases complexity and labor. Flat slabs eliminate beams and rely on uniform slab thickness or subtle drops for load transfer, simplifying formwork but demanding precise quality control and reinforcement placement to prevent deflections and cracking. Construction challenges for drop panels include formwork shaping and congestion around columns, while flat slabs require stringent control of concrete quality and continuous vibration to avoid honeycombing and ensure structural integrity.

Cost Implications: Drop Panel vs Flat Slab

Drop panels typically reduce slab thickness around columns, enhancing load capacity and minimizing the amount of concrete and reinforcement required, which can lower material and labor costs compared to flat slabs. Flat slabs eliminate beams entirely, offering faster formwork and construction times that may reduce labor expenses but often demand higher reinforcement quantities and increased slab thickness, potentially raising material costs. Your choice between drop panels and flat slabs should weigh initial construction costs against long-term structural efficiency and project-specific budget constraints.

Applications and Suitable Use Cases

Drop panels are ideal for heavy load-bearing structures such as parking garages, high-rise buildings, and industrial facilities due to increased shear strength around columns. Flat slabs suit residential buildings, office spaces, and commercial complexes where architectural flexibility and faster formwork installation are priorities. Both systems offer distinct advantages based on load requirements and structural design preferences.

Advantages and Limitations Comparison

Drop panels provide enhanced shear strength and reduce slab thickness around columns, improving load distribution and minimizing punching shear risks. Flat slabs offer faster construction and greater architectural flexibility by eliminating beams, but their limited shear capacity often requires thicker slabs or additional reinforcement. Your choice depends on balancing structural efficiency against design complexity and construction speed.

Choosing Between Drop Panel and Flat Slab Systems

Choosing between drop panel and flat slab systems depends on structural load requirements and architectural flexibility; drop panels provide enhanced shear strength and reduced slab thickness around columns, making them ideal for heavy loads and high-occupancy buildings. Flat slabs offer simpler formwork, faster construction, and more open interior space without beams, suitable for residential and commercial projects with moderate loads. Evaluating project-specific factors such as span length, column layout, and construction speed ensures optimal structural performance and cost efficiency.

Drop panel vs Flat slab Infographic

libmatt.com

libmatt.com