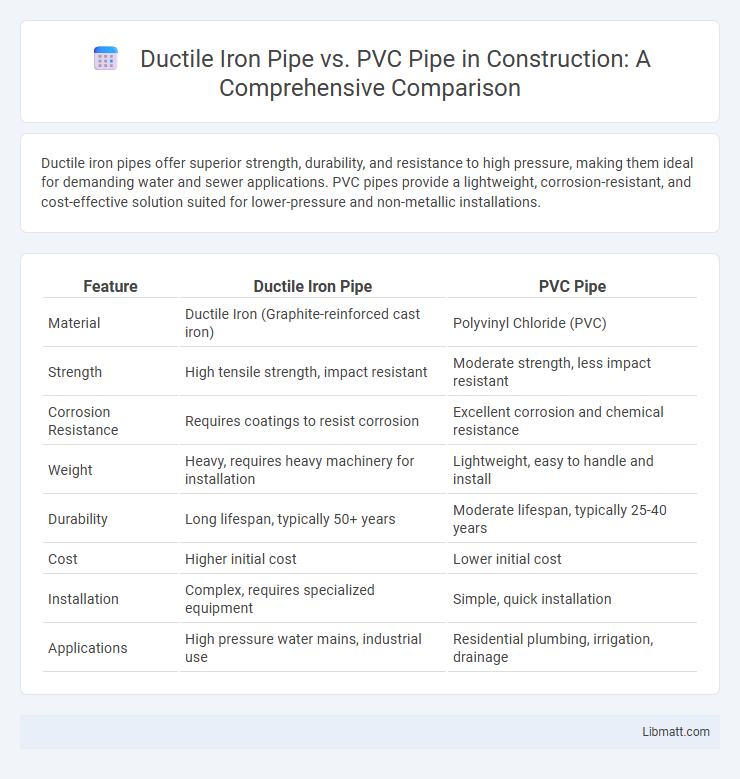

Ductile iron pipes offer superior strength, durability, and resistance to high pressure, making them ideal for demanding water and sewer applications. PVC pipes provide a lightweight, corrosion-resistant, and cost-effective solution suited for lower-pressure and non-metallic installations.

Table of Comparison

| Feature | Ductile Iron Pipe | PVC Pipe |

|---|---|---|

| Material | Ductile Iron (Graphite-reinforced cast iron) | Polyvinyl Chloride (PVC) |

| Strength | High tensile strength, impact resistant | Moderate strength, less impact resistant |

| Corrosion Resistance | Requires coatings to resist corrosion | Excellent corrosion and chemical resistance |

| Weight | Heavy, requires heavy machinery for installation | Lightweight, easy to handle and install |

| Durability | Long lifespan, typically 50+ years | Moderate lifespan, typically 25-40 years |

| Cost | Higher initial cost | Lower initial cost |

| Installation | Complex, requires specialized equipment | Simple, quick installation |

| Applications | High pressure water mains, industrial use | Residential plumbing, irrigation, drainage |

Introduction to Ductile Iron and PVC Pipes

Ductile iron pipes, made from cast iron alloyed with nodular graphite, offer high strength, durability, and excellent resistance to pressure and impact, making them ideal for water and wastewater systems. PVC pipes, composed of polyvinyl chloride, provide corrosion resistance, lightweight handling, and cost-effectiveness, widely used in residential water supply, irrigation, and drainage applications. Both materials serve critical roles in modern infrastructure, with ductile iron favored for heavy-duty uses and PVC preferred for ease of installation and chemical resistance.

Material Composition and Properties

Ductile iron pipe is made from cast iron alloyed with small amounts of magnesium, giving it enhanced strength, ductility, and resistance to impact and pressure, making it ideal for high-load and high-pressure water and sewage applications. PVC pipe is composed of polyvinyl chloride, a lightweight, corrosion-resistant plastic that is chemically inert and offers excellent resistance to abrasion and most chemicals, but it has lower tensile strength compared to ductile iron. Your choice between ductile iron and PVC pipes should consider the specific demands of the project, including load-bearing requirements and environmental exposure.

Strength and Durability Comparison

Ductile iron pipes offer superior strength and impact resistance compared to PVC pipes, making them ideal for high-pressure and heavy-load applications. Their enhanced durability is attributed to the material's toughness and corrosion resistance, which extends the service life significantly beyond that of PVC pipes. PVC pipes, while corrosion-resistant and lightweight, are more susceptible to cracking under heavy loads and extreme temperatures, limiting their use in demanding infrastructure projects.

Corrosion Resistance and Longevity

Ductile iron pipe offers superior corrosion resistance due to its protective zinc and bituminous coatings, extending its lifespan in harsh environments up to 100 years. PVC pipe resists corrosion from most chemicals and does not rust, but it is susceptible to UV degradation and physical damage, potentially reducing its longevity to around 50 years. The choice between ductile iron and PVC pipe depends on environmental conditions and required service life, with ductile iron preferred for high-durability applications and PVC for chemical resistance and lightweight needs.

Installation Process and Flexibility

Ductile iron pipe requires heavy equipment and skilled labor for trenching, laying, and jointing, making the installation process more labor-intensive compared to PVC pipe, which is lightweight and easier to handle with simpler mechanical or solvent welding joints. The flexibility of ductile iron pipe allows for some deflection and resistance to external loads, beneficial in unstable soil conditions, whereas PVC pipe offers less flexibility but greater ease of alignment and adjustment during installation. You should consider the site conditions and installation complexity when choosing between ductile iron and PVC pipes to optimize project efficiency.

Cost Analysis: Initial and Lifetime Expenses

Ductile iron pipes have higher initial costs compared to PVC pipes, but their durability often results in lower lifetime expenses due to reduced maintenance and longer service life. PVC pipes are generally more affordable upfront and easier to install, yet they may incur higher replacement and repair costs over time because of susceptibility to cracking and UV damage. Your decision between ductile iron and PVC should weigh the balance between upfront investment and anticipated long-term performance to optimize overall cost efficiency.

Environmental Impact and Sustainability

Ductile iron pipes offer superior recyclability and longer lifespan, reducing environmental waste compared to PVC pipes, which are derived from non-renewable petroleum resources and present challenges in recycling due to chemical additives. The manufacturing of ductile iron involves lower carbon emissions when compared to PVC production, contributing to reduced environmental footprints. PVC pipes, while lightweight and resistant to corrosion, often generate toxic byproducts during disposal, making ductile iron the more sustainable choice in infrastructure projects aiming for eco-friendly durability.

Performance Under Pressure and Load

Ductile iron pipes exhibit superior performance under high pressure and heavy load conditions due to their robust material composition and ability to withstand greater tensile strength and impact forces compared to PVC pipes. PVC pipes, while corrosion-resistant and lightweight, are more prone to deformation and failure under extreme pressure and heavy load situations, limiting their use in high-demand infrastructure applications. Your choice between ductile iron and PVC should consider these performance characteristics to ensure long-term reliability and safety.

Maintenance Requirements and Repair

Ductile iron pipes demand regular maintenance involving corrosion monitoring and protective coating inspections to prevent rust and extend service life. In contrast, PVC pipes require minimal upkeep due to their corrosion resistance and durability against chemical damage. Repairing ductile iron pipes often involves specialized welding or sleeve techniques, whereas PVC pipes are typically repaired with solvent cement or mechanical couplings, making fixes faster and more cost-effective.

Applications and Suitability for Various Projects

Ductile iron pipes are preferred in high-pressure municipal water systems and sewer lines due to their strength, durability, and resistance to external loads, making them suitable for urban infrastructure and industrial projects. PVC pipes offer excellent chemical resistance, ease of installation, and cost-effectiveness, making them ideal for residential plumbing, irrigation, and low-pressure drainage systems. Choosing between ductile iron and PVC depends on project-specific requirements such as pressure, environmental conditions, and load-bearing needs.

Ductile iron pipe vs PVC pipe Infographic

libmatt.com

libmatt.com