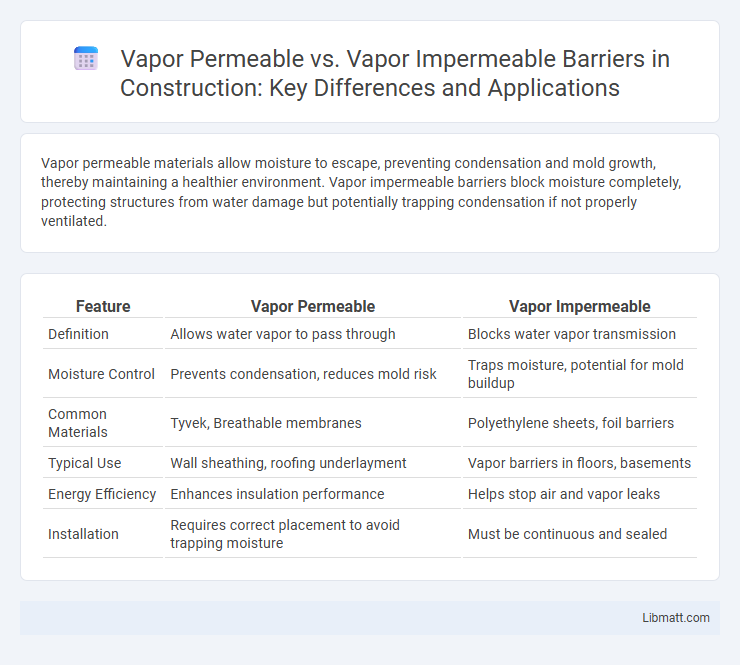

Vapor permeable materials allow moisture to escape, preventing condensation and mold growth, thereby maintaining a healthier environment. Vapor impermeable barriers block moisture completely, protecting structures from water damage but potentially trapping condensation if not properly ventilated.

Table of Comparison

| Feature | Vapor Permeable | Vapor Impermeable |

|---|---|---|

| Definition | Allows water vapor to pass through | Blocks water vapor transmission |

| Moisture Control | Prevents condensation, reduces mold risk | Traps moisture, potential for mold buildup |

| Common Materials | Tyvek, Breathable membranes | Polyethylene sheets, foil barriers |

| Typical Use | Wall sheathing, roofing underlayment | Vapor barriers in floors, basements |

| Energy Efficiency | Enhances insulation performance | Helps stop air and vapor leaks |

| Installation | Requires correct placement to avoid trapping moisture | Must be continuous and sealed |

Introduction to Vapor Permeability

Vapor permeability refers to a material's ability to allow water vapor to pass through it, influencing moisture control in building envelopes and clothing. Vapor permeable materials enhance breathability, reducing condensation and mold growth, while vapor impermeable materials block moisture, providing a strong barrier but risking trapped humidity. Understanding vapor permeability helps you select the right materials for energy efficiency and indoor air quality.

Understanding Vapor Permeable Materials

Vapor permeable materials allow moisture vapor to pass through, preventing condensation and mold growth within building assemblies by maintaining balanced humidity levels. Common examples include breathable membranes and certain insulation types, which enhance indoor air quality and structural durability. Vapor impermeable materials, in contrast, block moisture transmission, often leading to trapped vapor and potential damage if moisture management is inadequate.

Key Characteristics of Vapor Impermeable Materials

Vapor impermeable materials prevent moisture vapor from passing through, creating a complete barrier that protects underlying structures from water damage and mold growth. These materials are typically made from plastic films, rubber membranes, or metal sheets with extremely low permeability ratings, often measured in perms close to zero. Their primary use is in environments requiring strict moisture control, such as in roofing, foundation waterproofing, and industrial vapor barriers.

How Vapor Permeability Impacts Building Envelopes

Vapor permeability in building envelopes allows moisture vapor to escape, preventing condensation, mold growth, and structural damage caused by trapped moisture. Materials with higher vapor permeability, such as breathable membranes, promote indoor air quality and enhance durability by regulating moisture flow. In contrast, vapor impermeable barriers block moisture transmission, which can lead to moisture accumulation and compromise the envelope's integrity over time.

Moisture Control: Permeable vs Impermeable Solutions

Vapor permeable materials allow moisture vapor to escape, reducing the risk of condensation and mold growth within building assemblies. Vapor impermeable barriers block moisture vapor transmission entirely, which can trap moisture and potentially lead to structural damage if not properly managed. Effective moisture control depends on selecting the appropriate vapor permeability based on climate, building design, and intended use.

Common Applications of Vapor Permeable Barriers

Vapor permeable barriers are commonly used in building construction to allow moisture to escape while protecting structures from water intrusion, making them ideal for roofing underlays, wall sheathing, and house wraps. These barriers enable interior humidity to pass through, reducing the risk of mold growth and structural damage in climates with varying temperature and humidity levels. Your building projects benefit from vapor permeable barriers by maintaining indoor air quality and extending the lifespan of insulation materials.

Typical Uses of Vapor Impermeable Barriers

Vapor impermeable barriers are commonly used in construction to prevent moisture infiltration in foundation walls, below-grade structures, and roofing assemblies where water vapor penetration must be strictly controlled. These barriers help protect insulation and structural components from condensation-related damage, ensuring building durability and energy efficiency. Typical materials include polyethylene sheets and elastomeric coatings specifically designed for vapor resistance.

Benefits and Drawbacks of Each Option

Vapor permeable materials allow moisture to escape, reducing the risk of mold and structural damage, which is essential for maintaining indoor air quality and prolonging building lifespan; however, they may permit unwanted air infiltration, potentially decreasing energy efficiency. Vapor impermeable barriers prevent moisture penetration, enhancing insulation performance and energy savings by sealing air leaks, but they can trap moisture within walls, leading to condensation, rot, and compromised structural integrity. Choosing between vapor permeable and impermeable options depends on climate, building design, and moisture control requirements to optimize durability and comfort.

Selecting the Right Barrier for Your Project

Choosing between vapor permeable and vapor impermeable barriers depends on your project's moisture control needs and climate conditions. Vapor permeable barriers allow moisture vapor to escape, reducing the risk of mold and structural damage in humid environments. Vapor impermeable barriers block all moisture, offering superior protection in areas prone to high water exposure but require careful installation to prevent trapped condensation.

Conclusion: Which is Best—Vapor Permeable or Impermeable?

Vapor permeable materials are best for environments requiring moisture control and breathability, preventing mold and structural damage by allowing water vapor to escape. Vapor impermeable materials are ideal for situations demanding airtightness and moisture barriers, effectively blocking moisture penetration in areas prone to heavy water exposure. Choosing the best option depends on specific application needs, climate conditions, and building design goals to balance moisture management and energy efficiency.

Vapor permeable vs Vapor impermeable Infographic

libmatt.com

libmatt.com