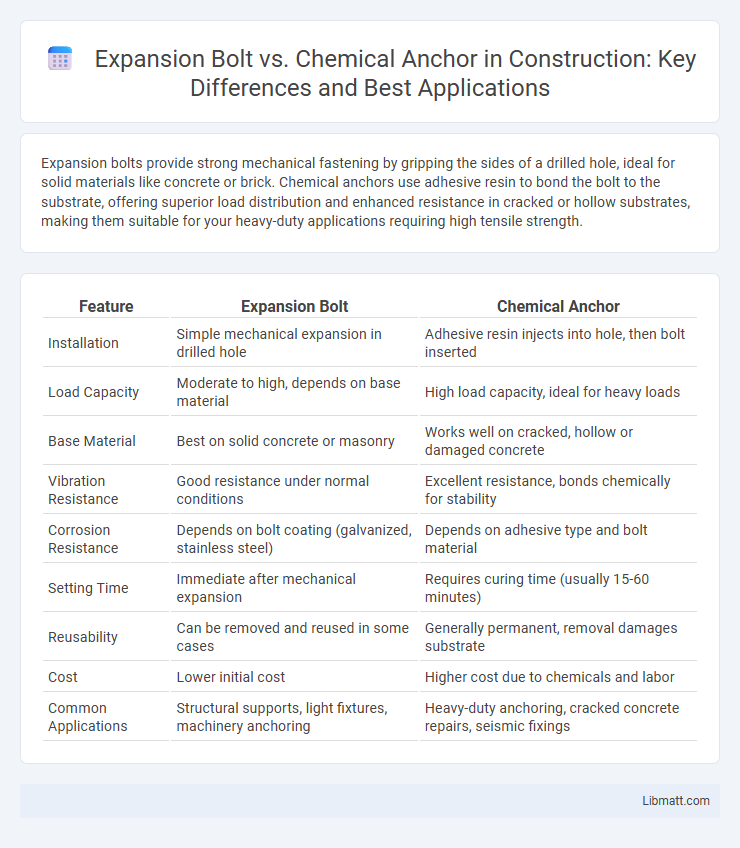

Expansion bolts provide strong mechanical fastening by gripping the sides of a drilled hole, ideal for solid materials like concrete or brick. Chemical anchors use adhesive resin to bond the bolt to the substrate, offering superior load distribution and enhanced resistance in cracked or hollow substrates, making them suitable for your heavy-duty applications requiring high tensile strength.

Table of Comparison

| Feature | Expansion Bolt | Chemical Anchor |

|---|---|---|

| Installation | Simple mechanical expansion in drilled hole | Adhesive resin injects into hole, then bolt inserted |

| Load Capacity | Moderate to high, depends on base material | High load capacity, ideal for heavy loads |

| Base Material | Best on solid concrete or masonry | Works well on cracked, hollow or damaged concrete |

| Vibration Resistance | Good resistance under normal conditions | Excellent resistance, bonds chemically for stability |

| Corrosion Resistance | Depends on bolt coating (galvanized, stainless steel) | Depends on adhesive type and bolt material |

| Setting Time | Immediate after mechanical expansion | Requires curing time (usually 15-60 minutes) |

| Reusability | Can be removed and reused in some cases | Generally permanent, removal damages substrate |

| Cost | Lower initial cost | Higher cost due to chemicals and labor |

| Common Applications | Structural supports, light fixtures, machinery anchoring | Heavy-duty anchoring, cracked concrete repairs, seismic fixings |

Introduction to Expansion Bolts and Chemical Anchors

Expansion bolts provide strong mechanical fastening by anchoring into concrete or masonry through the expansion of a metal sleeve, ideal for heavy-load applications. Chemical anchors utilize epoxy or resin adhesives to bond threaded rods or rebar within drilled holes, offering superior load distribution and vibration resistance. Both fastening methods ensure secure attachment but differ in installation techniques, load capacities, and suitability for various structural materials.

How Expansion Bolts Work

Expansion bolts work by inserting a metal sleeve around a threaded bolt into a drilled hole, and when the bolt is tightened, the sleeve expands against the surrounding material, creating a secure mechanical grip. The pressure generated by the expanding sleeve distributes load evenly, making them ideal for use in concrete, masonry, and stone substrates. Designed for high-strength applications, expansion bolts provide reliable anchoring without the need for adhesives or curing times typical of chemical anchors.

How Chemical Anchors Function

Chemical anchors function by injecting a two-component resin into a drilled hole, where the resin undergoes a curing process that bonds the anchor rod or bolt securely to the concrete or masonry substrate. This creates a strong, durable bond that distributes load evenly and resists vibrations and heavy stresses better than mechanical expansion bolts. You can rely on chemical anchors for enhanced adhesion in cracked or brittle materials where traditional expansion bolts might fail.

Key Differences Between Expansion Bolts and Chemical Anchors

Expansion bolts rely on mechanical friction to secure heavy loads in concrete by expanding against the hole walls, offering immediate load-bearing capacity. Chemical anchors utilize adhesive resins to bond the anchor to the substrate, providing superior load distribution and resistance to vibrations and environmental factors. Your choice depends on specific structural requirements, installation conditions, and the need for long-term durability.

Load Capacity Comparison

Expansion bolts provide reliable load capacity through mechanical interlock with the base material, typically offering higher immediate shear and tensile strength in solid concrete applications. Chemical anchors, utilizing adhesive bonding, often achieve superior load capacity in cracked or hollow substrates by distributing stress effectively and enhancing pull-out resistance. Load capacity for both depends greatly on factors such as base material integrity, installation precision, and environmental conditions, but chemical anchors outperform expansion bolts in scenarios requiring enhanced vibration resistance and long-term durability.

Installation Process: Step-by-Step

Expansion bolts require drilling a hole into the base material, cleaning out debris, inserting the bolt, and tightening the nut to expand the anchor against the hole walls for secure fastening. Chemical anchors involve drilling a hole, thoroughly cleaning the hole with a brush and air blower, injecting the resin or adhesive, inserting the threaded rod or rebar into the wet resin, and allowing curing time for the chemical bond to develop strength. The choice between these installation processes depends on factors like load requirements, base material type, and environmental conditions.

Suitable Applications for Expansion Bolts

Expansion bolts are ideal for securing heavy loads in solid materials like concrete and masonry where high shear and tensile strength are required. Common applications include fixing structural steel frameworks, attaching machinery bases, and anchoring safety barriers in construction and industrial settings. They perform best in environments where immediate load-bearing capacity and ease of installation are critical without the curing time required by chemical anchors.

Ideal Uses for Chemical Anchors

Chemical anchors are ideal for heavy-duty applications requiring high load-bearing capacity and superior bonding in cracked or porous concrete where expansion bolts may fail. They provide excellent resistance to vibration and dynamic loads, making them suitable for structural supports, machinery installation, and seismic retrofitting. You benefit from enhanced flexibility in positioning and stronger adherence in irregular substrate conditions compared to expansion bolts.

Pros and Cons of Each Anchoring Solution

Expansion bolts offer strong mechanical holding power suitable for solid concrete and heavy loads but can cause cracking during installation and may loosen under vibration. Chemical anchors provide a versatile, high-strength bond in cracked or hollow structures and reduce stress on the base material; however, they require careful surface preparation and curing time before load application. Choosing the right anchor depends on Your project's material conditions, load requirements, and installation constraints.

Choosing the Right Anchor for Your Project

Expansion bolts provide strong mechanical fastening by expanding against the base material, making them ideal for solid concrete and heavy load applications. Chemical anchors use epoxy or resin to bond into the drilled hole, offering superior holding power in cracked or hollow substrates and flexibility for irregular installation conditions. Selecting the right anchor depends on factors like base material, load requirements, environmental conditions, and installation ease, with expansion bolts suited for simple, high-strength tasks and chemical anchors preferred for complex or sensitive substrates.

Expansion bolt vs chemical anchor Infographic

libmatt.com

libmatt.com