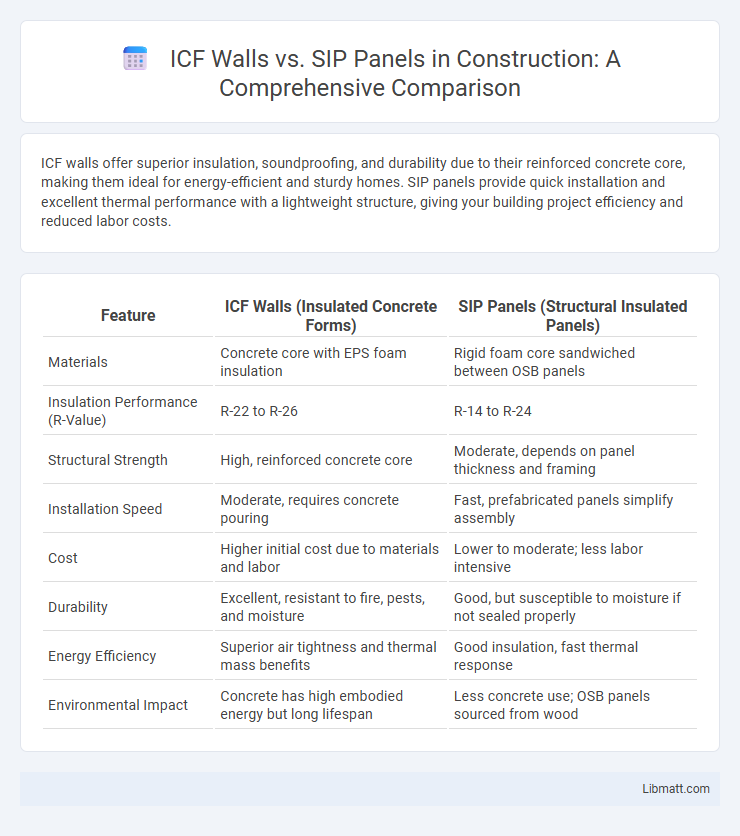

ICF walls offer superior insulation, soundproofing, and durability due to their reinforced concrete core, making them ideal for energy-efficient and sturdy homes. SIP panels provide quick installation and excellent thermal performance with a lightweight structure, giving your building project efficiency and reduced labor costs.

Table of Comparison

| Feature | ICF Walls (Insulated Concrete Forms) | SIP Panels (Structural Insulated Panels) |

|---|---|---|

| Materials | Concrete core with EPS foam insulation | Rigid foam core sandwiched between OSB panels |

| Insulation Performance (R-Value) | R-22 to R-26 | R-14 to R-24 |

| Structural Strength | High, reinforced concrete core | Moderate, depends on panel thickness and framing |

| Installation Speed | Moderate, requires concrete pouring | Fast, prefabricated panels simplify assembly |

| Cost | Higher initial cost due to materials and labor | Lower to moderate; less labor intensive |

| Durability | Excellent, resistant to fire, pests, and moisture | Good, but susceptible to moisture if not sealed properly |

| Energy Efficiency | Superior air tightness and thermal mass benefits | Good insulation, fast thermal response |

| Environmental Impact | Concrete has high embodied energy but long lifespan | Less concrete use; OSB panels sourced from wood |

Introduction to ICF Walls and SIP Panels

ICF walls, or Insulated Concrete Forms, consist of hollow foam blocks stacked and filled with concrete, providing superior thermal insulation, soundproofing, and structural strength. SIP panels, or Structural Insulated Panels, feature a rigid foam core sandwiched between two oriented strand boards (OSB), offering quick assembly and high energy efficiency. Both building systems are popular for sustainable construction but differ in installation methods, material composition, and overall performance benefits.

Material Composition of ICF Walls vs SIP Panels

ICF walls consist of expanded polystyrene (EPS) foam blocks or panels filled with reinforced concrete, providing superior thermal insulation and structural strength. SIP panels combine rigid foam insulation sandwiched between oriented strand board (OSB) sheathing, resulting in a lightweight, energy-efficient building component. Your choice depends on whether you prioritize concrete durability with ICF or the high insulation-to-weight ratio of SIPs.

Installation Process Comparison

ICF walls require stacking interlocking foam blocks and filling them with concrete, demanding careful alignment and time for curing. SIP panels consist of pre-fabricated foam insulation sandwiched between structural boards, enabling faster installation with fewer on-site adjustments. Your choice impacts project timelines, as SIP panels often reduce labor and construction time compared to the more intensive assembly of ICF systems.

Energy Efficiency and Insulation Performance

ICF walls provide superior energy efficiency by combining reinforced concrete with rigid foam insulation, creating an airtight and thermally resistant barrier that reduces heat loss and lowers utility costs. SIP panels consist of insulated foam sandwiched between structural facings, offering consistent thermal performance and minimizing air infiltration for exceptional insulation. Choosing between ICF walls and SIP panels influences your building's overall energy efficiency and comfort levels by optimizing insulation performance.

Structural Strength and Durability

ICF walls consist of reinforced concrete sandwiched between insulating foam panels, offering exceptional structural strength and superior resistance to natural disasters such as hurricanes and earthquakes. SIP panels combine a rigid foam core with oriented strand board (OSB) facings, providing strong thermal insulation but slightly less impact resistance compared to ICF walls. Both materials ensure durable construction, yet ICF walls excel in load-bearing capacity and long-term resilience against moisture and pests.

Soundproofing and Acoustic Properties

ICF walls provide excellent soundproofing due to their dense concrete core and insulating foam, effectively reducing airborne noise and vibrations. SIP panels, while offering decent acoustic insulation with their foam core, generally allow more sound transmission compared to ICF walls because of their lighter structural components. For projects prioritizing superior noise reduction and enhanced acoustic comfort, ICF walls typically outperform SIP panels in minimizing sound penetration.

Cost Analysis: Upfront and Long-Term

Insulated Concrete Form (ICF) walls typically involve higher upfront costs due to materials and labor but offer significant energy savings through superior insulation and durability, reducing long-term expenses. Structural Insulated Panels (SIP) panels usually have lower initial installation costs and provide efficient thermal performance, but may require more maintenance over time, impacting overall lifecycle costs. When comparing cost analysis, ICF walls excel in long-term durability and energy efficiency, while SIP panels offer a more budget-friendly entry with moderate ongoing savings.

Environmental Impact and Sustainability

ICF walls use expanded polystyrene foam combined with concrete, which offers excellent energy efficiency but relies on petroleum-based materials and has a higher embodied carbon footprint compared to SIP panels. SIP panels consist of an insulating foam core sandwiched between oriented strand board, providing superior thermal performance with less material waste and often incorporate recycled or renewable materials, reducing environmental impact. Your choice between ICF and SIPs can affect your building's sustainability, with SIPs generally contributing to lower greenhouse gas emissions and easier recycling at end-of-life.

Design Flexibility and Architectural Applications

ICF walls offer superior design flexibility with their modular blocks that can be easily shaped into curves, arches, and custom angles, accommodating a wide range of architectural styles. SIP panels provide consistent thickness and thermal performance but are generally limited to flat, straight wall applications due to their rigid panel structure. Architects favor ICFs for complex, innovative designs while SIPs are preferred for streamlined, efficient construction in conventional layouts.

Conclusion: Choosing Between ICF Walls and SIP Panels

ICF walls offer superior durability, energy efficiency, and soundproofing, making them ideal for long-term insulation and structural integrity. SIP panels provide faster installation times, excellent thermal performance, and design flexibility, suited for projects requiring quick assembly and customization. Your choice depends on balancing construction speed with long-term energy savings and structural needs.

ICF walls vs SIP panels Infographic

libmatt.com

libmatt.com