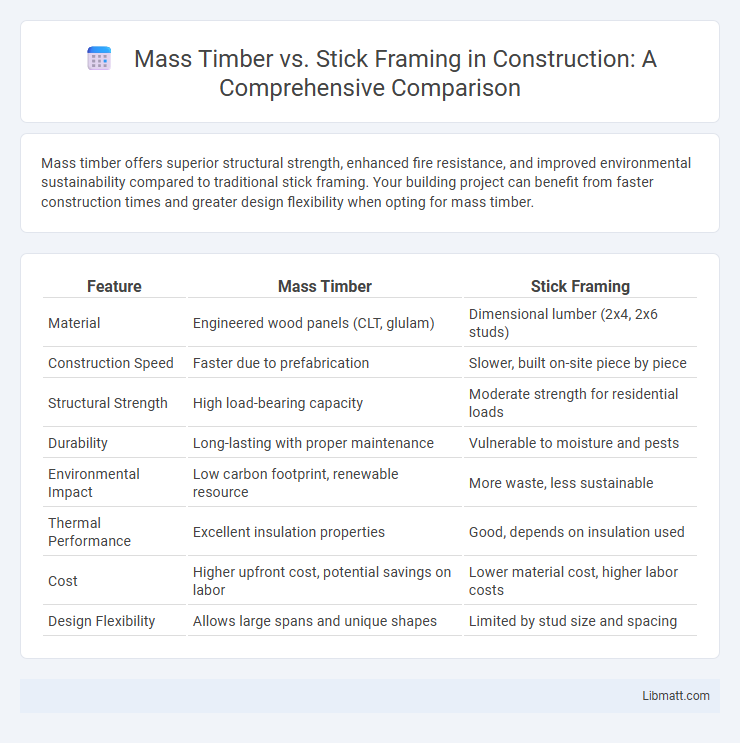

Mass timber offers superior structural strength, enhanced fire resistance, and improved environmental sustainability compared to traditional stick framing. Your building project can benefit from faster construction times and greater design flexibility when opting for mass timber.

Table of Comparison

| Feature | Mass Timber | Stick Framing |

|---|---|---|

| Material | Engineered wood panels (CLT, glulam) | Dimensional lumber (2x4, 2x6 studs) |

| Construction Speed | Faster due to prefabrication | Slower, built on-site piece by piece |

| Structural Strength | High load-bearing capacity | Moderate strength for residential loads |

| Durability | Long-lasting with proper maintenance | Vulnerable to moisture and pests |

| Environmental Impact | Low carbon footprint, renewable resource | More waste, less sustainable |

| Thermal Performance | Excellent insulation properties | Good, depends on insulation used |

| Cost | Higher upfront cost, potential savings on labor | Lower material cost, higher labor costs |

| Design Flexibility | Allows large spans and unique shapes | Limited by stud size and spacing |

Introduction to Mass Timber and Stick Framing

Mass timber construction utilizes large engineered wood panels such as cross-laminated timber (CLT) for structural elements, offering benefits like enhanced sustainability and faster assembly compared to traditional stick framing. Stick framing relies on individually cut lumber pieces assembled on-site, which provides flexibility in design but often results in longer construction timelines and higher waste. The choice between mass timber and stick framing depends on project scale, environmental goals, and budget constraints.

Key Differences Between Mass Timber and Stick Framing

Mass timber construction utilizes large, prefabricated wood panels or beams, offering superior strength, fire resistance, and faster assembly compared to traditional stick framing, which relies on smaller, individual dimensional lumber pieces assembled on-site. Mass timber provides enhanced sustainability benefits due to its renewable material source and lower carbon footprint, while stick framing remains more flexible and cost-effective for smaller-scale projects. Differences in load-bearing capacity, thermal performance, and design versatility highlight mass timber's suitability for mid-rise to high-rise buildings versus stick framing's dominance in residential and low-rise construction.

Structural Performance Comparison

Mass timber offers superior structural performance compared to stick framing due to its increased strength-to-weight ratio and ability to span longer distances without intermediate supports. Engineered wood components like cross-laminated timber (CLT) provide enhanced rigidity and dimensional stability, reducing deflection and improving load distribution in buildings. Stick framing, while more traditional and flexible for small-scale projects, generally requires additional structural reinforcement to achieve the same load-bearing capacity as mass timber systems.

Sustainability and Environmental Impact

Mass timber construction significantly reduces carbon emissions by using renewable wood sources that sequester CO2, contrasting with stick framing's reliance on energy-intensive materials like steel and concrete. Life cycle assessments show mass timber's lower embodied energy and decreased waste generation promote sustainable building practices. Forest stewardship certification ensures responsible timber harvesting, enhancing mass timber's environmental benefits over traditional stick framing methods.

Cost Analysis: Mass Timber vs. Stick Framing

Mass timber construction typically incurs higher upfront material costs compared to stick framing, yet offers significant savings in labor due to faster assembly and reduced on-site work. Stick framing uses widely available dimensional lumber and familiar techniques, resulting in lower initial expenses but longer build times that can increase overall project costs. Long-term economic benefits of mass timber include improved energy efficiency and reduced foundation requirements, potentially offsetting its premium price through operational savings.

Construction Speed and Efficiency

Mass timber construction significantly reduces build time compared to traditional stick framing due to prefabricated panels and large structural components that are quickly assembled on-site. Stick framing requires more labor-intensive processes with numerous small components, leading to longer construction periods and increased potential for errors. Your project can benefit from mass timber's streamlined efficiency, which enhances productivity and shortens overall schedules.

Fire Resistance and Safety Considerations

Mass timber exhibits superior fire resistance compared to stick framing due to its ability to char on the surface, which creates a protective layer that slows combustion and maintains structural integrity longer during a fire event. Stick framing, typically constructed with dimensional lumber, is more vulnerable to rapid ignition and structural failure under intense heat, posing higher safety risks in fire scenarios. Fire safety codes increasingly recognize mass timber's performance, prompting its integration in mid-rise and tall wood buildings where enhanced fire resilience is critical.

Design Flexibility and Architectural Possibilities

Mass timber offers superior design flexibility due to its ability to span longer distances without intermediate supports, enabling open floor plans and innovative architectural forms. Stick framing, relying on closely spaced studs and joists, limits the size of open spaces and restricts creative structural layouts. Architects prefer mass timber for its versatility in creating cantilevers, curves, and large-volume spaces that enhance aesthetic and functional possibilities.

Regulatory Challenges and Building Codes

Mass timber construction faces evolving regulatory challenges as building codes across regions adapt to accommodate its fire resistance, structural performance, and sustainability benefits. Unlike traditional stick framing, which is widely approved with established code provisions, mass timber requires rigorous testing and performance evidence to meet fire safety standards and height restrictions. Understanding these regulatory nuances can help you navigate compliance effectively and leverage mass timber's potential for innovative, eco-friendly building projects.

Future Trends in Timber Construction

Mass timber is revolutionizing the future of timber construction with its superior sustainability, strength, and faster assembly compared to traditional stick framing. Innovations like cross-laminated timber (CLT) and nail-laminated timber (NLT) enable taller, more durable, and energy-efficient buildings that reduce carbon footprints. Your projects can benefit from these advancements, embracing a shift towards eco-friendly construction methods that meet growing regulatory demands and urban density challenges.

Mass timber vs stick framing Infographic

libmatt.com

libmatt.com