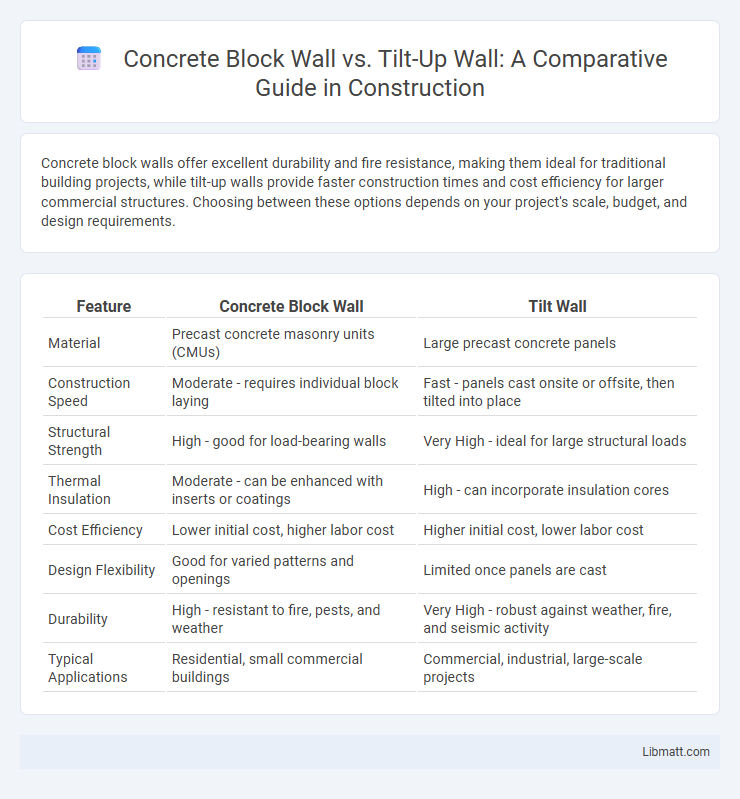

Concrete block walls offer excellent durability and fire resistance, making them ideal for traditional building projects, while tilt-up walls provide faster construction times and cost efficiency for larger commercial structures. Choosing between these options depends on your project's scale, budget, and design requirements.

Table of Comparison

| Feature | Concrete Block Wall | Tilt Wall |

|---|---|---|

| Material | Precast concrete masonry units (CMUs) | Large precast concrete panels |

| Construction Speed | Moderate - requires individual block laying | Fast - panels cast onsite or offsite, then tilted into place |

| Structural Strength | High - good for load-bearing walls | Very High - ideal for large structural loads |

| Thermal Insulation | Moderate - can be enhanced with inserts or coatings | High - can incorporate insulation cores |

| Cost Efficiency | Lower initial cost, higher labor cost | Higher initial cost, lower labor cost |

| Design Flexibility | Good for varied patterns and openings | Limited once panels are cast |

| Durability | High - resistant to fire, pests, and weather | Very High - robust against weather, fire, and seismic activity |

| Typical Applications | Residential, small commercial buildings | Commercial, industrial, large-scale projects |

Introduction to Concrete Block Wall and Tilt Wall

Concrete block walls consist of stacked, mortar-bound concrete masonry units, offering versatility, fire resistance, and sound insulation for various construction projects. Tilt walls are large, precast concrete panels formed horizontally on-site and then lifted into position, providing quick installation, structural strength, and design flexibility. Understanding both methods helps you choose the optimal solution based on project requirements and budget constraints.

Material Composition and Properties

Concrete block walls are made from individual concrete masonry units composed of cement, aggregates, and water, offering excellent compressive strength and thermal insulation. Tilt-up walls consist of large, precast concrete panels poured on-site with higher concrete density and integrated reinforcement, providing superior structural integrity and faster construction. Your choice depends on the required load-bearing capacity, insulation needs, and project timeline due to these inherent material and property differences.

Construction Process Comparison

Concrete block walls require individual placement of hollow or solid blocks, laying each with mortar in a staggered pattern that allows for flexibility and adjustments during construction. Tilt wall construction involves casting large concrete panels horizontally on-site or in a factory, then lifting and securing them into place using cranes, enabling faster erection and reduced labor on site. The tilt wall method offers quicker structural assembly with fewer joints, whereas concrete block walls provide more adaptability for irregular layouts and modifications during the building process.

Cost Analysis: Concrete Block vs Tilt Wall

Concrete block walls typically have lower initial material and labor costs compared to tilt walls, making them a cost-effective choice for smaller projects or where budget constraints are significant. Tilt walls, while having higher upfront expenses due to specialized equipment and panel fabrication, often result in faster construction times and reduced labor costs on-site, potentially offsetting initial investments. Long-term cost benefits of tilt walls include enhanced structural performance and durability, which can lower maintenance and repair expenses compared to concrete block walls.

Design Flexibility and Aesthetic Options

Concrete block walls offer high design flexibility with various sizes, textures, and finishes, allowing customization for both structural and aesthetic needs. Tilt wall construction provides smooth, uniform surfaces ideal for large-scale projects but limits texture variation and intricate detailing. You can achieve more diverse architectural styles and personalized visual effects with concrete block walls compared to the more uniform appearance of tilt walls.

Structural Strength and Durability

Concrete block walls exhibit high compressive strength due to their solid masonry construction, making them ideal for load-bearing applications in residential and commercial buildings. Tilt-up walls, cast on-site and lifted into place, offer enhanced structural integrity and durability through their monolithic design, which allows for better resistance to lateral forces such as wind and seismic activity. Both wall types provide robust durability, but tilt walls tend to perform better in extreme environmental conditions due to their continuous concrete mass and reduced joint vulnerabilities.

Thermal and Sound Insulation Performance

Concrete block walls provide moderate thermal insulation due to their dense material but often require additional insulation to meet energy efficiency standards, while their mass effectively reduces sound transmission. Tilt-up walls, cast on site with concrete panels, offer superior thermal mass, stabilizing indoor temperatures and enhancing energy efficiency, and exhibit strong soundproofing capabilities because of their solid construction. Both systems contribute to sound insulation, but tilt-up walls generally outperform concrete block walls in thermal regulation owing to their continuous panel design.

Speed of Installation

Concrete block walls require individual placement and mortar curing, resulting in slower installation times compared to tilt walls, which are precast and set in place quickly using cranes. Tilt wall panels allow for rapid construction of large sections, significantly reducing onsite labor and project duration. Choosing tilt walls can speed up your building process, especially for projects with tight deadlines.

Maintenance and Longevity

Concrete block walls require periodic inspection for mortar joint cracks and occasional repointing to maintain structural integrity, with a typical lifespan exceeding 50 years when properly maintained. Tilt-up walls, constructed as large precast panels, offer enhanced durability with minimal maintenance needs, primarily requiring surface sealing and occasional joint inspection, often lasting 40 to 60 years under normal conditions. Both systems benefit from protective coatings to resist weathering, but tilt-up walls generally provide superior longevity due to their monolithic design and reduced joint vulnerabilities.

Sustainability and Environmental Impact

Concrete block walls offer higher thermal mass, improving energy efficiency and reducing heating and cooling demands, which supports sustainability goals in construction. Tilt-up walls, while faster to install, typically involve larger material volumes and higher energy consumption during manufacturing due to onsite casting, potentially increasing their environmental footprint. Both systems benefit from recycled content in concrete, but careful consideration of material sourcing and lifecycle emissions is essential to minimize overall environmental impact.

Concrete block wall vs Tilt wall Infographic

libmatt.com

libmatt.com