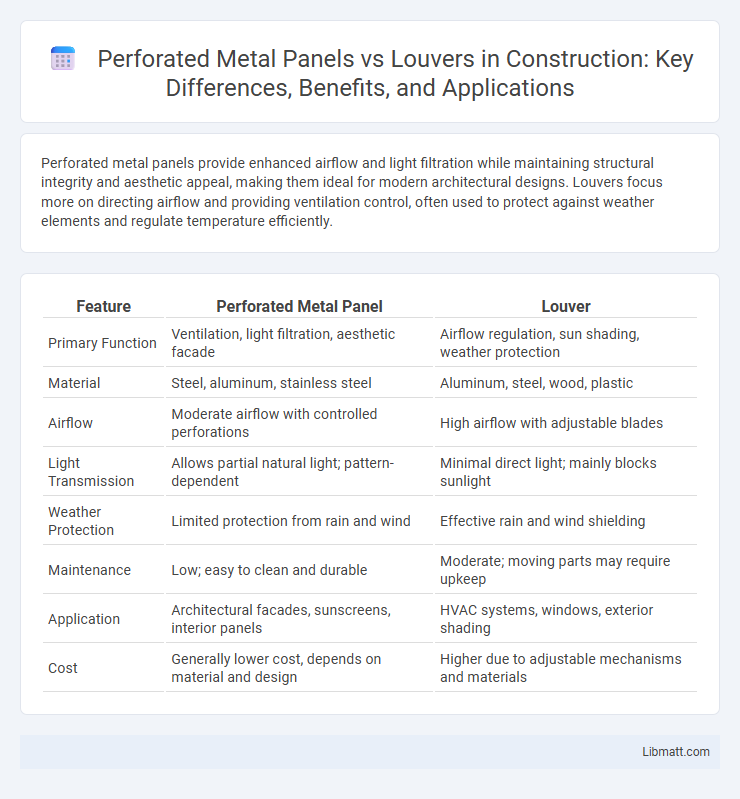

Perforated metal panels provide enhanced airflow and light filtration while maintaining structural integrity and aesthetic appeal, making them ideal for modern architectural designs. Louvers focus more on directing airflow and providing ventilation control, often used to protect against weather elements and regulate temperature efficiently.

Table of Comparison

| Feature | Perforated Metal Panel | Louver |

|---|---|---|

| Primary Function | Ventilation, light filtration, aesthetic facade | Airflow regulation, sun shading, weather protection |

| Material | Steel, aluminum, stainless steel | Aluminum, steel, wood, plastic |

| Airflow | Moderate airflow with controlled perforations | High airflow with adjustable blades |

| Light Transmission | Allows partial natural light; pattern-dependent | Minimal direct light; mainly blocks sunlight |

| Weather Protection | Limited protection from rain and wind | Effective rain and wind shielding |

| Maintenance | Low; easy to clean and durable | Moderate; moving parts may require upkeep |

| Application | Architectural facades, sunscreens, interior panels | HVAC systems, windows, exterior shading |

| Cost | Generally lower cost, depends on material and design | Higher due to adjustable mechanisms and materials |

Introduction to Perforated Metal Panels and Louvers

Perforated metal panels consist of sheets with evenly spaced holes, offering excellent ventilation, light filtration, and aesthetic appeal, commonly used in architectural facades and interior design. Louvers are angled slats designed to control airflow, block direct sunlight, and provide privacy while allowing ventilation in HVAC systems and building exteriors. Choosing between perforated metal panels and louvers depends on your specific needs for airflow control, light management, and visual impact.

Core Functional Differences Between Perforated Panels and Louvers

Perforated metal panels feature numerous small holes that allow for airflow, light filtration, and sound attenuation while providing partial visibility and aesthetic appeal. Louvers consist of angled slats designed primarily to direct air or light flow, block rain or direct sunlight, and offer privacy without completely obstructing ventilation. You should choose perforated panels when transparency and decorative patterns are important, whereas louvers are ideal for controlling environmental elements and ensuring effective ventilation.

Material and Design Options

Perforated metal panels offer diverse material choices such as aluminum, steel, and stainless steel, with customizable hole sizes, patterns, and thicknesses that enhance aesthetics and ventilation. Louvers typically use durable metals like aluminum or galvanized steel, featuring angled slats designed for airflow control and weather resistance. Your selection depends on whether you prioritize the decorative flexibility of perforated panels or the functional airflow management provided by louvers.

Aesthetic and Visual Impact

Perforated metal panels offer a modern, sleek aesthetic with customizable patterns that create dynamic light and shadow effects, enhancing architectural appeal. Louvers provide a more traditional look, emphasizing function over form, with slats designed mainly for ventilation and sun control, resulting in a uniform visual texture. The choice between perforated panels and louvers significantly influences building facades, balancing artistic expression against functional design elements.

Ventilation and Airflow Performance

Perforated metal panels deliver superior ventilation by allowing a higher percentage of open area, facilitating optimal airflow and effective air exchange. Louvers control airflow direction while providing protection against rain and debris but typically restrict airflow more than perforated panels due to their angled slats. For applications prioritizing maximum ventilation and unrestricted airflow, perforated metal panels are preferred, whereas louvers balance airflow with weatherproofing needs.

Sun Shading and Light Control Capabilities

Perforated metal panels offer precise control over sunlight by filtering natural light, reducing glare, and maintaining visibility while allowing ventilation. Louvers provide adjustable sun shading by directing sunlight away from interior spaces, effectively reducing heat gain and enhancing privacy. Both solutions optimize daylight management, but perforated panels excel in diffusing light, whereas louvers offer dynamic shading adjustment.

Durability and Maintenance Requirements

Perforated metal panels offer superior durability due to their solid metal construction that resists corrosion and physical damage, making them ideal for harsh environments. Louvers, while effective for ventilation, often require more frequent maintenance to prevent clogging from debris and potential corrosion due to their angled slats and exposed edges. Maintenance for perforated panels typically involves minimal cleaning to preserve appearance, whereas louvers necessitate regular inspections and cleaning to maintain airflow efficiency and structural integrity.

Acoustic Performance Comparison

Perforated metal panels offer superior acoustic performance by effectively reducing noise through sound absorption, especially when combined with an insulating backing. Louvers primarily function for ventilation and airflow, providing limited sound attenuation compared to perforated panels. For applications demanding enhanced noise control, perforated metal panels are the preferred choice due to their ability to dissipate sound energy while maintaining structural integrity.

Cost Analysis and Installation Considerations

Perforated metal panels generally offer a more cost-effective solution compared to louvers due to lower material expenses and simplified manufacturing processes. Installation of perforated panels is typically quicker and requires fewer specialized tools or components, reducing labor costs and project timelines. Your choice should factor in not only initial purchase price but also long-term maintenance and ease of replacement associated with each system.

Best Applications and Use Cases

Perforated metal panels are ideal for applications requiring airflow and light filtration, such as architectural facades, sunshades, and acoustic ceilings, where aesthetics and ventilation are crucial. Louvers excel in environments needing controlled airflow and weather protection, commonly used in HVAC systems, building ventilation, and industrial exhausts to prevent water and debris ingress. Choosing between these materials depends on Your need for ventilation type, visual impact, and environmental exposure in specific use cases.

Perforated metal panel vs louver Infographic

libmatt.com

libmatt.com