Expansion joints are designed to accommodate the movement caused by thermal expansion and contraction in building materials, preventing cracks and structural damage, while control joints are intentionally placed lines that guide where concrete or masonry will crack in a controlled manner to maintain structural integrity. Understanding the difference helps you choose the right joint type for managing stress and preserving the longevity of your construction project.

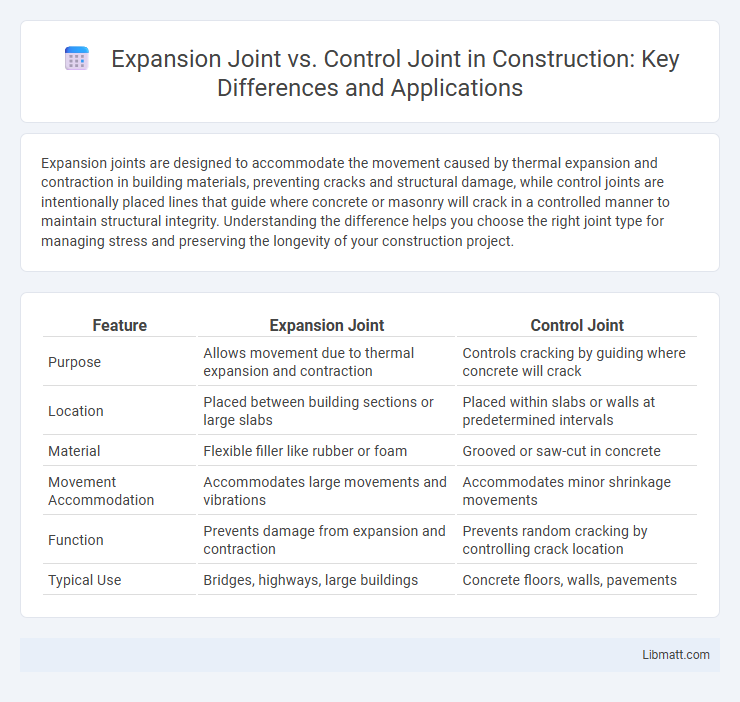

Table of Comparison

| Feature | Expansion Joint | Control Joint |

|---|---|---|

| Purpose | Allows movement due to thermal expansion and contraction | Controls cracking by guiding where concrete will crack |

| Location | Placed between building sections or large slabs | Placed within slabs or walls at predetermined intervals |

| Material | Flexible filler like rubber or foam | Grooved or saw-cut in concrete |

| Movement Accommodation | Accommodates large movements and vibrations | Accommodates minor shrinkage movements |

| Function | Prevents damage from expansion and contraction | Prevents random cracking by controlling crack location |

| Typical Use | Bridges, highways, large buildings | Concrete floors, walls, pavements |

Introduction to Expansion Joints and Control Joints

Expansion joints accommodate building movement caused by temperature changes, moisture, or seismic activity, preventing structural damage by absorbing stress. Control joints are intentional, weakened planes designed to manage concrete cracking by directing where cracks occur as the material cures and contracts. Understanding the distinct roles of expansion joints and control joints helps you ensure structural integrity and longevity in construction projects.

Definition of Expansion Joints

Expansion joints are flexible gaps or spaces installed in concrete structures, roads, or piping systems to absorb thermal expansion and contraction, preventing cracks and structural damage. They accommodate movement caused by temperature changes, moisture, and load stress, ensuring the integrity and longevity of buildings and infrastructure. Your construction projects benefit from correctly designed expansion joints by reducing maintenance costs and enhancing durability in dynamic environments.

Definition of Control Joints

Control joints are intentional, planned cracks in concrete or masonry structures designed to manage and direct the natural shrinkage and cracking that occurs as materials dry and cure. Unlike expansion joints, which accommodate movements caused by temperature changes or external forces, control joints are strategically placed to prevent random cracking by creating weakened planes where the concrete can crack safely. Understanding the purpose of control joints helps you enhance the durability and appearance of your concrete surfaces.

Key Differences Between Expansion and Control Joints

Expansion joints accommodate structural movement caused by thermal expansion and contraction, preventing cracks by absorbing stress. Control joints are intentional weak points in concrete that direct where cracks occur due to shrinkage during drying. Understanding these distinctions helps you choose the right joint to maintain structural integrity and longevity.

Functions and Purposes of Each Joint Type

Expansion joints accommodate structural movement caused by thermal expansion and contraction, preventing cracks and damage in bridges, sidewalks, and buildings. Control joints intentionally create weak points in concrete to direct cracking in a controlled manner, enhancing durability by reducing random fracturing. Understanding the distinct purposes of these joints helps you manage stress and prolong the lifespan of your construction projects.

Common Materials Used in Expansion and Control Joints

Expansion joints and control joints often utilize materials like rubber, neoprene, and silicone for flexibility and durability. Concrete and metal inserts are common for control joints to manage cracking in slabs, while expansion joints may include compressible fillers such as foam or fiberboard to absorb movement. Your choice of materials depends on environmental conditions and structural requirements to ensure longevity and performance.

Installation Methods for Expansion Joints vs Control Joints

Expansion joints are installed by placing flexible materials such as elastomers or metal strips at predetermined intervals, allowing for thermal movement and structural shifts without causing cracks. Control joints, typically cut or tooled into concrete slabs during installation, create intentional weak points that guide cracking due to shrinkage and stress. Your choice between these methods depends on the structure's movement expectations and the specific function required for expansion or crack control.

Typical Applications in Construction Projects

Expansion joints are typically used in large-scale construction projects such as bridges, highways, and long concrete slabs to accommodate thermal expansion and contraction, preventing structural damage. Control joints are commonly applied in concrete floors, walls, and pavements to manage cracks caused by shrinkage during curing. Your choice between expansion and control joints depends on the specific stress management needs and the type of structure involved.

Pros and Cons: Expansion Joints vs Control Joints

Expansion joints effectively accommodate building movement caused by temperature changes and seismic activity, reducing the risk of structural damage but require regular maintenance to prevent water infiltration and debris buildup. Control joints help manage concrete shrinkage and cracking by directing where cracks occur, offering a cost-effective solution but do not accommodate large structural movements like expansion joints. Choosing between expansion joints and control joints depends on factors such as movement allowance, environmental conditions, and maintenance capacity.

Conclusion: Choosing the Right Joint for Your Project

Selecting the appropriate joint depends on the specific functions required: expansion joints accommodate structural movement caused by temperature fluctuations, while control joints manage cracking by directing stress in concrete slabs. Understanding project conditions such as environmental factors, material type, and load impact ensures optimal joint performance and longevity. Prioritizing the correct joint type enhances structural integrity and reduces maintenance costs over the lifespan of the construction.

Expansion joint vs Control joint Infographic

libmatt.com

libmatt.com