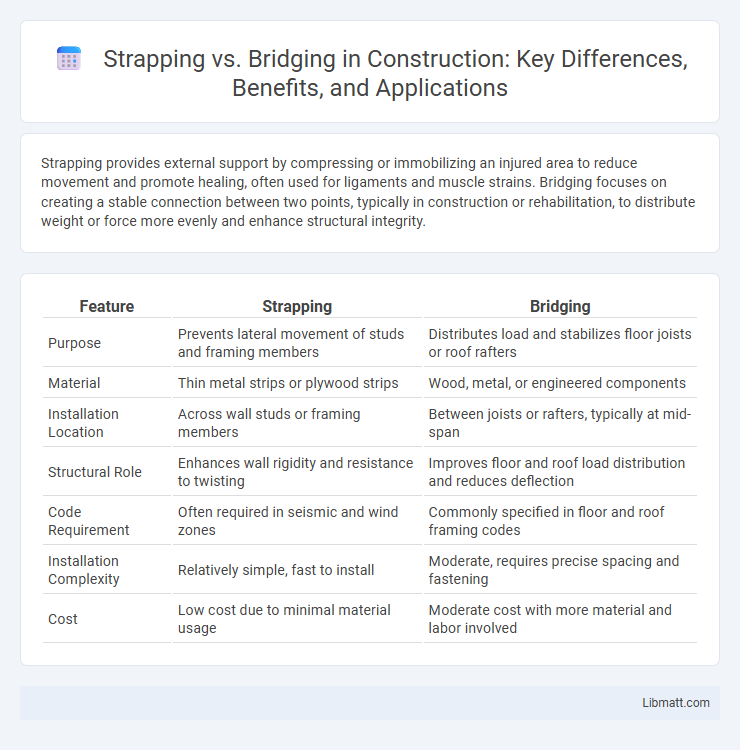

Strapping provides external support by compressing or immobilizing an injured area to reduce movement and promote healing, often used for ligaments and muscle strains. Bridging focuses on creating a stable connection between two points, typically in construction or rehabilitation, to distribute weight or force more evenly and enhance structural integrity.

Table of Comparison

| Feature | Strapping | Bridging |

|---|---|---|

| Purpose | Prevents lateral movement of studs and framing members | Distributes load and stabilizes floor joists or roof rafters |

| Material | Thin metal strips or plywood strips | Wood, metal, or engineered components |

| Installation Location | Across wall studs or framing members | Between joists or rafters, typically at mid-span |

| Structural Role | Enhances wall rigidity and resistance to twisting | Improves floor and roof load distribution and reduces deflection |

| Code Requirement | Often required in seismic and wind zones | Commonly specified in floor and roof framing codes |

| Installation Complexity | Relatively simple, fast to install | Moderate, requires precise spacing and fastening |

| Cost | Low cost due to minimal material usage | Moderate cost with more material and labor involved |

Introduction to Strapping and Bridging

Strapping and bridging are essential techniques used to reinforce and stabilize framing structures in construction. Strapping involves installing metal or wood strips across framing members to prevent movement and add rigidity, while bridging refers to horizontal or diagonal braces placed between joists or studs to distribute loads evenly and reduce twisting or warping. Understanding both methods enhances the durability and safety of your building framework.

Definition of Strapping

Strapping refers to the process of installing flexible metal or non-metal bands to reinforce or secure framing members in construction, preventing lateral movement and enhancing structural stability. This technique is commonly used in wood-framed walls to resist shear forces caused by wind or seismic activity. Understanding the role of strapping can help you improve your building's durability and compliance with safety regulations.

Definition of Bridging

Bridging refers to the technique of connecting two or more points to distribute load or stress efficiently, often used in construction and engineering to enhance structural stability. This method helps prevent joint failure by creating a continuous support system that transfers forces across the connected elements. Understanding bridging allows you to choose the right approach for reinforcing frameworks and improving overall durability.

Key Differences Between Strapping and Bridging

Strapping and bridging are two critical techniques used in structural framing to enhance stability and load distribution. Strapping typically involves thin metal strips fastened diagonally across framing members to resist lateral forces and prevent twisting. Bridging consists of solid blocks or cross braces installed between joists to maintain spacing and distribute loads evenly, providing rigidity and reducing deflection in floor or ceiling systems.

Applications of Strapping Techniques

Strapping techniques are widely applied in packaging industries for securing heavy loads, pallets, and bundled materials during transportation and storage. Common materials used in strapping include polyester, steel, and polypropylene, chosen based on strength requirements and environmental conditions. Strapping ensures stability and safety, making it essential in sectors such as construction, logistics, and manufacturing.

Applications of Bridging Techniques

Bridging techniques are extensively used in carpet installation to provide additional support over uneven or unstable subfloors, preventing movement that could lead to tearing or wrinkling. These methods are essential in areas with variable humidity or temperature, such as basements or commercial spaces, where dimensional changes are frequent. Bridging also enhances the durability of carpets in high-traffic zones by distributing stress evenly across the backing and preventing premature wear.

Advantages of Strapping

Strapping offers superior flexibility and ease of installation compared to bridging, making it ideal for securing ductwork and improving structural rigidity without extensive modifications. It reduces vibration and noise transmission, enhancing overall system performance and durability. Your HVAC system benefits from strapping's ability to provide reliable support while minimizing material costs and labor time.

Advantages of Bridging

Bridging provides enhanced stability by evenly distributing loads across joists, reducing deflection and minimizing structural movement in flooring systems. It improves load transfer efficiency, which results in increased durability and resistance to vibration compared to strapping. This method also facilitates easier alignment during installation and offers superior long-term performance in residential and commercial construction.

Factors to Consider When Choosing Between Strapping and Bridging

Choosing between strapping and bridging depends on load distribution, structural stability, and installation requirements. Strapping enhances lateral support by tying framing members, ideal for resisting wind or seismic forces, while bridging provides diagonal or cross bracing, improving stiffness and preventing twisting. Material compatibility, code compliance, and ease of maintenance also influence the selection of the optimal reinforcement method.

Conclusion: Strapping vs Bridging – Which is Best?

Strapping provides a rigid connection that enhances structural stability by restricting movement between components, making it ideal for load-bearing applications and seismic resistance. Bridging improves load distribution and prevents lateral buckling in framing systems, contributing to overall frame integrity under compression loads. The choice between strapping and bridging depends on the specific structural requirements, with strapping preferred for rigidity and bridging optimal for load distribution and buckling prevention.

Strapping vs bridging Infographic

libmatt.com

libmatt.com