Two-way slabs distribute loads in both directions to beams and columns, making them suitable for square or nearly square panels, while one-way slabs transfer loads primarily in one direction to parallel supporting beams. Your choice between these slab types depends on the structural layout and load distribution requirements of your construction project.

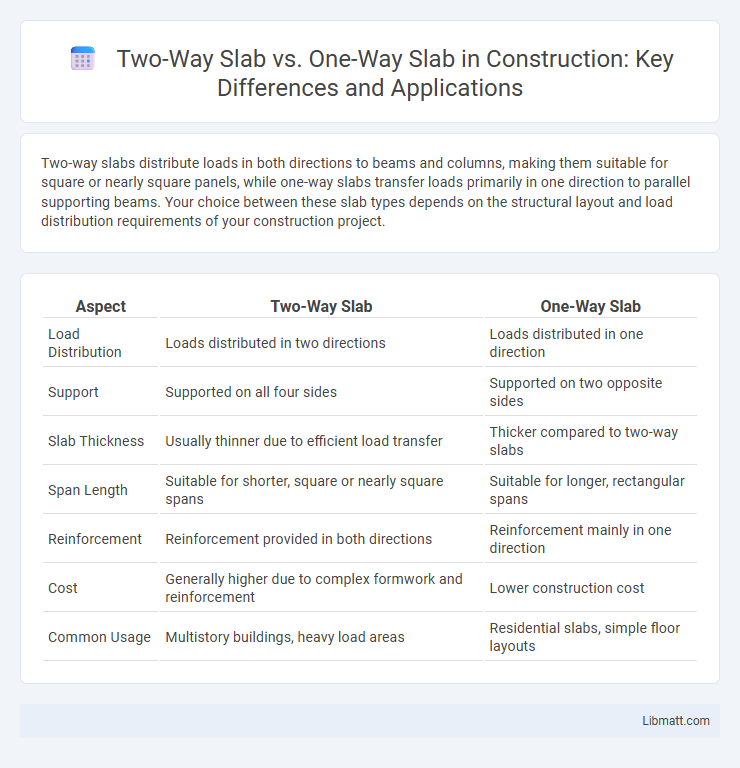

Table of Comparison

| Aspect | Two-Way Slab | One-Way Slab |

|---|---|---|

| Load Distribution | Loads distributed in two directions | Loads distributed in one direction |

| Support | Supported on all four sides | Supported on two opposite sides |

| Slab Thickness | Usually thinner due to efficient load transfer | Thicker compared to two-way slabs |

| Span Length | Suitable for shorter, square or nearly square spans | Suitable for longer, rectangular spans |

| Reinforcement | Reinforcement provided in both directions | Reinforcement mainly in one direction |

| Cost | Generally higher due to complex formwork and reinforcement | Lower construction cost |

| Common Usage | Multistory buildings, heavy load areas | Residential slabs, simple floor layouts |

Introduction to Slab Systems in Construction

Two-way slabs are structural elements supported on all four sides, distributing loads in two directions, while one-way slabs transfer loads primarily in one direction to parallel supports. Two-way slab systems are typically used for square or nearly square layouts, optimizing load distribution and reducing slab thickness. One-way slabs are common in rectangular spans with longer lengths, requiring beams or walls to carry loads along the slab's length.

Definition of One-Way Slab

A one-way slab is a structural element where the load is primarily transferred in one direction, spanning between parallel supports such as beams or walls. It is typically rectangular, with the longer span significantly greater than the shorter span, causing bending to occur mainly perpendicular to the shorter side. This design is efficient for floors and roofs in buildings where the slab spans in only one direction.

Definition of Two-Way Slab

A two-way slab is a reinforced concrete slab supported on all four sides, designed to distribute loads in both directions, providing enhanced structural support compared to a one-way slab that transfers load primarily in one direction. This slab system is typically used when the ratio of slab length to width is less than two, ensuring efficient load distribution across both axes. Understanding the definition of a two-way slab helps you select the most suitable slab type for balanced load-bearing and structural integrity in your construction project.

Key Differences Between One-Way and Two-Way Slabs

One-way slabs primarily distribute loads in a single direction between parallel supports, making them ideal for rectangular spans where length significantly exceeds width. Two-way slabs transfer loads in both directions to supports, providing enhanced load distribution for square or nearly square spans. Your choice depends on structural requirements, with two-way slabs offering greater stiffness and load-carrying efficiency in multi-directional support conditions.

Structural Behavior and Load Distribution

Two-way slabs transfer loads in both directions to supporting beams or columns, exhibiting bidirectional bending and offering enhanced strength and stiffness for square or nearly square panels. One-way slabs primarily bend in a single direction, transferring loads to two opposite supports, making them suitable for rectangular panels with a longer span in one direction. The structural behavior of two-way slabs results in more efficient load distribution and reduced thickness compared to one-way slabs, which rely on reinforcement primarily in one direction for load resistance.

Applications and Suitability of Each Type

Two-way slabs are ideal for square or nearly square floor layouts in commercial buildings, parking garages, and residential complexes where load distribution occurs in two directions, enhancing structural efficiency and reducing beam requirements. One-way slabs suit rectangular layouts with longer spans in one direction, commonly used in corridors, driveways, and simple floor systems where loads primarily transfer to parallel beams. Selection depends on structural geometry, load patterns, and cost-effectiveness, with two-way slabs preferred for heavier loads and complex layouts, while one-way slabs offer simplicity and savings in straightforward designs.

Construction Methods and Reinforcement Details

Two-way slabs are supported by beams on all four sides and require reinforcement in both directions, typically using a grid of steel bars to resist bending stresses. One-way slabs rest on beams or walls on two opposite sides only, with reinforcement primarily placed in the longer span direction to handle bending moments. Construction of two-way slabs involves casting a uniform thickness slab with evenly distributed reinforcement, while one-way slabs often feature thicker edges or ribs where support concentration demands additional reinforcement.

Advantages and Disadvantages Comparison

Two-way slabs distribute loads in two directions, providing higher load capacity and reducing the need for beams, which enhances structural efficiency in square or nearly square panels. One-way slabs primarily transfer loads in one direction, making them simpler and more cost-effective for rectangular spans but less suitable for heavy or complex load distributions. While two-way slabs offer improved flexibility and better performance under uneven loading, they are more expensive and require more complex formwork and reinforcement compared to one-way slabs.

Cost Implications and Material Efficiency

Two-way slabs typically incur higher initial costs due to increased reinforcement requirements and more complex formwork compared to one-way slabs, which use less steel and simpler support systems. Material efficiency in two-way slabs is optimized by distributing loads along both directions, reducing slab thickness and concrete volume for square or nearly square layouts. One-way slabs, ideal for rectangular spans, minimize material use by transferring loads primarily in one direction, leading to cost savings in linear support structures and steel reinforcements.

Conclusion: Choosing the Right Slab System

Two-way slabs distribute loads in both directions, offering greater strength and reducing slab thickness for larger spans, while one-way slabs transfer loads in a single direction, suitable for narrow or rectangular layouts with closely spaced supports. Your choice depends on structural requirements, span dimensions, and load distribution needs, ensuring cost-effectiveness and safety. Selecting the right slab system optimizes material use and enhances overall building performance.

Two-way slab vs one-way slab Infographic

libmatt.com

libmatt.com