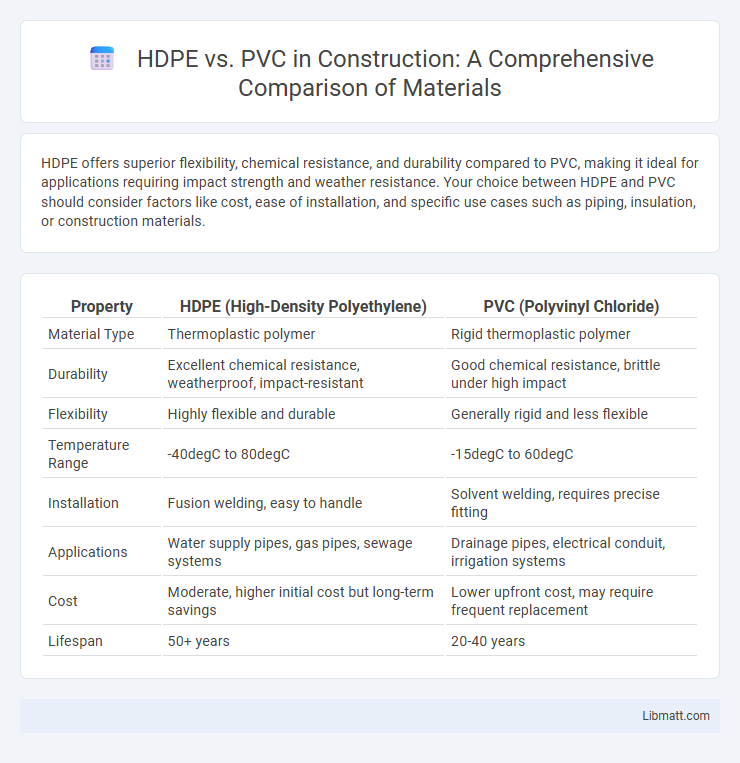

HDPE offers superior flexibility, chemical resistance, and durability compared to PVC, making it ideal for applications requiring impact strength and weather resistance. Your choice between HDPE and PVC should consider factors like cost, ease of installation, and specific use cases such as piping, insulation, or construction materials.

Table of Comparison

| Property | HDPE (High-Density Polyethylene) | PVC (Polyvinyl Chloride) |

|---|---|---|

| Material Type | Thermoplastic polymer | Rigid thermoplastic polymer |

| Durability | Excellent chemical resistance, weatherproof, impact-resistant | Good chemical resistance, brittle under high impact |

| Flexibility | Highly flexible and durable | Generally rigid and less flexible |

| Temperature Range | -40degC to 80degC | -15degC to 60degC |

| Installation | Fusion welding, easy to handle | Solvent welding, requires precise fitting |

| Applications | Water supply pipes, gas pipes, sewage systems | Drainage pipes, electrical conduit, irrigation systems |

| Cost | Moderate, higher initial cost but long-term savings | Lower upfront cost, may require frequent replacement |

| Lifespan | 50+ years | 20-40 years |

Introduction to HDPE and PVC

High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC) are two widely used thermoplastic polymers with distinct properties and applications. HDPE is known for its high strength-to-density ratio, excellent chemical resistance, and flexibility, making it ideal for piping, containers, and plastic bottles. PVC stands out for its durability, fire resistance, and versatility in construction materials, electrical cables, and medical devices, offering your projects reliable performance under varying conditions.

Chemical Composition and Structure

HDPE (High-Density Polyethylene) consists of long chains of ethylene monomers (C2H4), creating a linear, tightly packed molecular structure with minimal branching, giving it high density and crystallinity. PVC (Polyvinyl Chloride) is composed of vinyl chloride monomers (C2H3Cl), featuring a carbon backbone with chlorine atoms attached, resulting in a more rigid, chemically resistant polymer with distinct polar characteristics. The presence of chlorine in PVC imparts flame retardancy and chemical resistance, whereas HDPE's non-polar hydrocarbons provide flexibility and excellent impact resistance.

Key Physical Properties

HDPE boasts high tensile strength, excellent impact resistance, and superior chemical stability, making it ideal for demanding environments. PVC features rigidity, good tensile strength, and flame retardancy, but it is less flexible and more prone to UV degradation compared to HDPE. Your choice between HDPE and PVC should consider these physical properties based on the specific requirements of your application.

Durability and Lifespan Comparison

HDPE exhibits superior durability with exceptional resistance to impact, chemicals, and UV exposure, resulting in a lifespan of 50 years or more in harsh environments. PVC offers good durability and chemical resistance but is more susceptible to cracking and degradation under prolonged UV exposure, limiting its lifespan to around 20-30 years outdoors. The longevity of HDPE makes it the preferred choice for applications requiring extended durability and minimal maintenance.

Applications in Industry

HDPE is widely used in industries for manufacturing piping systems, plastic bottles, and geomembranes due to its high chemical resistance and durability. PVC is preferred in construction for electrical conduit, plumbing pipes, and window profiles because of its rigidity and fire resistance. Both materials serve crucial roles in automotive, packaging, and infrastructure sectors, with HDPE favored for flexibility and PVC for strength.

Environmental Impact and Sustainability

HDPE (High-Density Polyethylene) offers a lower environmental impact than PVC (Polyvinyl Chloride) due to its higher recyclability and fewer harmful chemical additives during production. PVC production releases toxic chlorine-based compounds, contributing to environmental pollution and health risks, whereas HDPE is more easily recycled and generates less hazardous waste. Your choice of HDPE supports sustainability efforts by reducing toxic emissions and promoting circular economy practices.

Installation and Maintenance Requirements

HDPE pipes require fusion welding for installation, offering seamless joints that reduce leak risks and minimize maintenance needs over time. PVC pipes use solvent cement for joining, which is quicker but may require regular inspections to check for cracks or leaks due to rigidity. Your choice between HDPE and PVC should consider installation complexity and ongoing maintenance to ensure durability and cost-effectiveness.

Cost Analysis: HDPE vs PVC

HDPE typically offers a lower initial cost compared to PVC, making it a cost-effective option for large-scale piping projects. PVC generally has higher upfront costs but provides greater chemical resistance and longer lifespan, potentially reducing maintenance expenses over time. Evaluating total cost of ownership involves considering HDPE's flexibility and installation savings against PVC's durability and resistance in specific environmental conditions.

Advantages and Disadvantages

HDPE offers superior chemical resistance, flexibility, and durability, making it ideal for piping and containers exposed to harsh environments, while PVC is known for its rigidity, affordability, and easy installation, commonly used in construction and plumbing. HDPE's main disadvantages include higher cost and difficulty with solvent welding, whereas PVC can become brittle over time and releases harmful fumes when burned. Both materials have distinct advantages and disadvantages dependent on application requirements such as temperature tolerance, corrosion resistance, and environmental impact.

Choosing Between HDPE and PVC

When choosing between HDPE and PVC, consider HDPE's superior chemical resistance, flexibility, and impact strength, making it ideal for water and gas distribution systems. PVC offers excellent rigidity, ease of installation, and cost-effectiveness, commonly used in drainage, plumbing, and irrigation applications. Evaluate project requirements such as pressure rating, environmental exposure, and budget to determine the most suitable material.

HDPE vs PVC Infographic

libmatt.com

libmatt.com