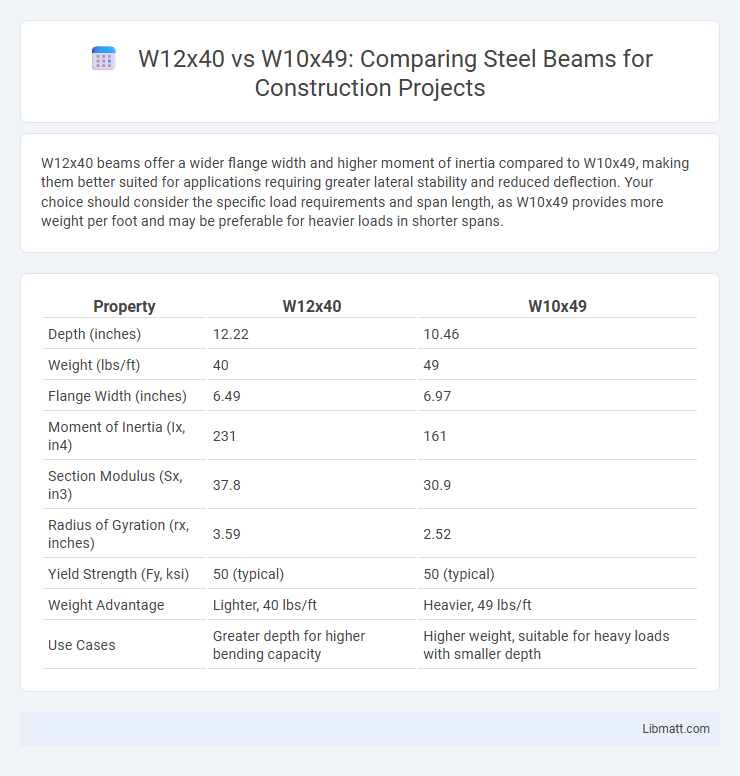

W12x40 beams offer a wider flange width and higher moment of inertia compared to W10x49, making them better suited for applications requiring greater lateral stability and reduced deflection. Your choice should consider the specific load requirements and span length, as W10x49 provides more weight per foot and may be preferable for heavier loads in shorter spans.

Table of Comparison

| Property | W12x40 | W10x49 |

|---|---|---|

| Depth (inches) | 12.22 | 10.46 |

| Weight (lbs/ft) | 40 | 49 |

| Flange Width (inches) | 6.49 | 6.97 |

| Moment of Inertia (Ix, in4) | 231 | 161 |

| Section Modulus (Sx, in3) | 37.8 | 30.9 |

| Radius of Gyration (rx, inches) | 3.59 | 2.52 |

| Yield Strength (Fy, ksi) | 50 (typical) | 50 (typical) |

| Weight Advantage | Lighter, 40 lbs/ft | Heavier, 49 lbs/ft |

| Use Cases | Greater depth for higher bending capacity | Higher weight, suitable for heavy loads with smaller depth |

Introduction to W12x40 and W10x49 Steel Beams

W12x40 and W10x49 steel beams are widely used structural steel sections with differing dimensions and load capacities, suited for various construction applications. The W12x40 beam has a nominal depth of 12.22 inches and weighs 40 pounds per foot, offering balance between strength and weight, while the W10x49 beam is slightly shallower at 10.21 inches deep but heavier at 49 pounds per foot, providing higher load-bearing capacity. Selection between these beams depends on factors such as span length, load requirements, and structural design specifications.

Key Dimensions and Specifications

The W12x40 steel beam features a depth of 12.22 inches and a weight of 40 pounds per foot, while the W10x49 beam has a depth of 10.18 inches and weighs 49 pounds per foot. The W12x40 offers a wider flange width of approximately 6.49 inches compared to the W10x49's 6.73 inches, influencing load distribution and structural support. Understanding these key dimensions and specifications helps you select the optimal beam for your construction requirements, balancing depth, weight, and strength.

Weight Comparison: W12x40 vs W10x49

The W12x40 steel beam weighs 40 pounds per foot, while the W10x49 weighs 49 pounds per foot, making the W10x49 significantly heavier despite its smaller depth. Your choice between these beams affects structural weight and load capacity, with the W10x49 offering greater strength due to its higher weight. Understanding this weight difference is crucial for optimizing steel use and ensuring efficient structural design.

Structural Strength and Load Capacity

The W12x40 steel beam offers greater structural strength and higher load capacity compared to the W10x49 due to its larger cross-sectional area and moment of inertia, which enhances bending resistance. Its deeper web and wider flange improve its ability to withstand heavier loads and reduce deflection under applied forces. While the W10x49 is heavier per foot, the W12x40 is more efficient for applications requiring maximum strength-to-weight ratio in beam selection.

Differences in Applications and Usage

The W12x40 steel beam is typically used in applications requiring moderate strength with a wider flange, making it ideal for longer spanning beams and columns in building frames where stability and load distribution are critical. The W10x49 beam, having a heavier weight per foot, offers greater strength and is preferred in heavy-load conditions such as industrial structures, bridges, and support girders needing higher load capacity and reduced deflection. While the W12x40 excels in scenarios demanding balanced strength and span, the W10x49 is suitable for more demanding structural requirements with increased weight and robustness.

Material Cost and Availability

The W12x40 steel beam typically offers lower material cost per unit length compared to the W10x49 due to its optimized weight-to-strength ratio, making it more cost-effective for many structural applications. Availability of W12x40 sections is generally broader within standard steel suppliers, driven by its common use in industrial and commercial construction projects. The W10x49, while heavier, may present higher costs and limited stock in some regions due to its less frequent demand and specialized use cases.

Installation Considerations

The W12x40 steel beam offers easier handling and installation due to its lighter weight compared to the W10x49, which can reduce labor costs and time on-site. The W10x49, though heavier, provides greater load capacity and structural strength, which may require more advanced equipment and careful placement during installation. Selecting between W12x40 and W10x49 depends on project-specific factors such as span length, load requirements, and site conditions that influence ease and efficiency of installation.

Flexural and Shear Performance

The W12x40 steel beam offers higher flexural capacity with a larger section modulus compared to the W10x49, enhancing its ability to resist bending stresses under heavy loads. In terms of shear performance, the W10x49 has a thicker web which improves shear strength and reduces web buckling risk, making it more suitable for applications with significant shear forces. Engineers must balance the enhanced bending resistance of the W12x40 with the superior shear capacity of the W10x49 when selecting the optimal beam for structural designs.

Longevity and Maintenance Factors

W12x40 steel beams typically offer enhanced longevity due to their greater depth, which provides superior load distribution and resistance to bending compared to W10x49 beams, reducing stress-related maintenance over time. You can expect the thicker flanges and web of the W12x40 to better withstand environmental wear, minimizing corrosion risk and the frequency of upkeep. While W10x49 beams are stronger in weight capacity, their slightly smaller size may lead to increased maintenance challenges in harsh conditions, impacting overall service life.

Choosing Between W12x40 and W10x49 Beams

Choosing between W12x40 and W10x49 steel beams depends on the specific structural requirements such as load capacity, span length, and weight considerations. W10x49 offers a heavier section with higher moment capacity suitable for longer spans or heavier loads, while W12x40 provides a wider flange that may enhance lateral stability and ease of connection in certain designs. Engineering assessment of bending moments, shear forces, and deflection criteria ensures optimal selection for safety, cost-efficiency, and performance.

W12x40 vs W10x49 (steel beam comparison) Infographic

libmatt.com

libmatt.com