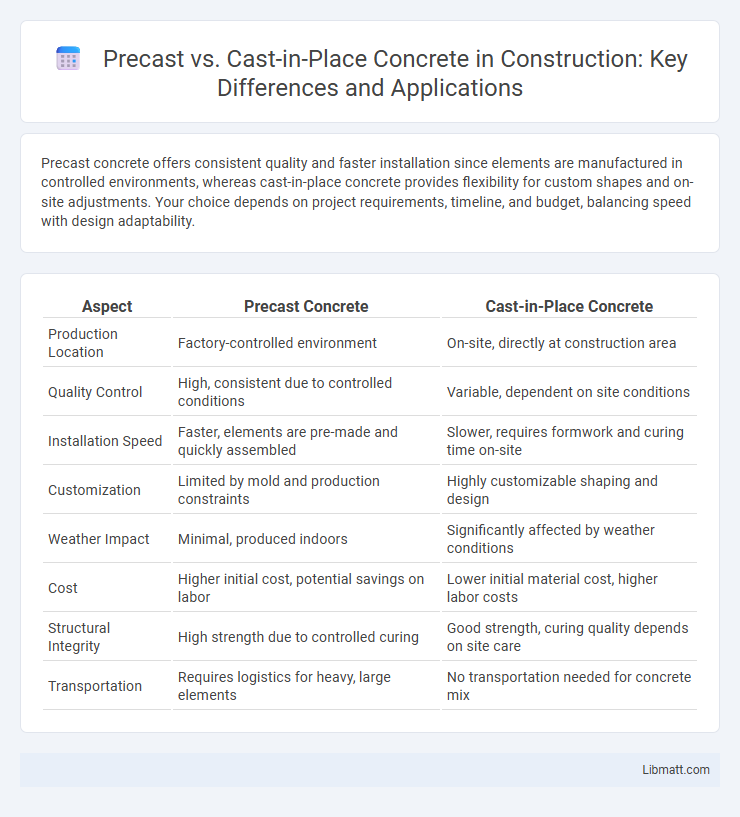

Precast concrete offers consistent quality and faster installation since elements are manufactured in controlled environments, whereas cast-in-place concrete provides flexibility for custom shapes and on-site adjustments. Your choice depends on project requirements, timeline, and budget, balancing speed with design adaptability.

Table of Comparison

| Aspect | Precast Concrete | Cast-in-Place Concrete |

|---|---|---|

| Production Location | Factory-controlled environment | On-site, directly at construction area |

| Quality Control | High, consistent due to controlled conditions | Variable, dependent on site conditions |

| Installation Speed | Faster, elements are pre-made and quickly assembled | Slower, requires formwork and curing time on-site |

| Customization | Limited by mold and production constraints | Highly customizable shaping and design |

| Weather Impact | Minimal, produced indoors | Significantly affected by weather conditions |

| Cost | Higher initial cost, potential savings on labor | Lower initial material cost, higher labor costs |

| Structural Integrity | High strength due to controlled curing | Good strength, curing quality depends on site care |

| Transportation | Requires logistics for heavy, large elements | No transportation needed for concrete mix |

Introduction to Precast and Cast-in-Place Concrete

Precast concrete is manufactured in controlled factory environments, ensuring consistent quality and faster installation times on-site. Cast-in-place concrete is poured directly into forms at the construction site, allowing for greater flexibility in shapes and customization. Your choice between precast and cast-in-place concrete depends on project requirements such as speed, design complexity, and site conditions.

Definition and Key Differences

Precast concrete refers to concrete elements that are cast and cured in a controlled factory environment before being transported to the construction site, offering consistent quality and faster installation. Cast-in-place concrete is poured directly at the construction site into formwork, allowing for greater flexibility in shape and customization but requiring longer curing times and more on-site labor. Key differences include precast's enhanced durability through factory-controlled processes and cast-in-place's adaptability to unique project specifications and structural integrations.

Advantages of Precast Concrete

Precast concrete offers significant advantages including enhanced quality control through factory production, resulting in consistent strength and durability. It reduces on-site construction time and labor costs by allowing components to be manufactured in parallel with site preparation. Additionally, precast elements improve project safety by minimizing on-site work and provide superior resistance to weather and environmental conditions.

Benefits of Cast-in-Place Concrete

Cast-in-place concrete offers superior structural integrity by forming a monolithic slab that enhances load distribution and resistance to seismic forces. The adaptability of cast-in-place methods allows for custom shapes and sizes tailored to specific project requirements, providing greater design flexibility. Your construction project can benefit from improved on-site quality control and reduced transportation costs since the concrete is poured directly where it is needed.

Limitations and Challenges of Precast Concrete

Precast concrete faces limitations such as transportation constraints due to the size and weight of panels, which can increase logistical costs and complexity. The need for precise factory-controlled production environments limits on-site flexibility, making adjustments during construction more challenging compared to cast-in-place concrete. Connections between precast units may require specialized labor and materials to ensure structural integrity and durability, posing challenges in seismic or highly dynamic environments.

Drawbacks of Cast-in-Place Concrete

Cast-in-place concrete often faces challenges such as longer construction timelines and higher labor costs due to on-site pouring and curing processes. Weather conditions can negatively impact the quality and consistency of the concrete, leading to potential delays and structural weaknesses. Your project may also encounter difficulties with formwork removal and limited quality control compared to precast concrete alternatives.

Cost Comparison: Precast vs Cast-in-Place

Precast concrete generally offers lower labor costs and faster installation compared to cast-in-place concrete, reducing overall project expenses. Cast-in-place concrete incurs higher formwork, labor, and curing time costs, especially on-site, leading to longer project durations and increased overhead. Choosing between precast and cast-in-place concrete depends on project scale, site conditions, and budget constraints, with precast favored for repetitive elements and expedited schedules.

Construction Speed and Efficiency

Precast concrete offers significantly faster construction speed due to off-site manufacturing under controlled conditions, enabling simultaneous site preparation and component fabrication. Cast-in-place concrete requires onsite formwork, pouring, and curing, which extends project timelines and labor intensity. The efficiency of precast systems reduces weather-related delays and enhances overall project scheduling flexibility.

Applications and Best Use Cases

Precast concrete is ideal for repetitive construction projects such as bridges, parking structures, and high-rise buildings where speed and quality control are critical. Cast-in-place concrete excels in custom, complex designs like foundations, slabs, and structures requiring seamless integration with existing elements. Choose precast for faster installation and uniformity, while cast-in-place suits flexible, site-specific applications demanding tailored shapes and reinforcement.

Sustainability and Environmental Impact

Precast concrete reduces environmental impact by minimizing waste and allowing for precise material use in controlled factory conditions, leading to less resource consumption compared to cast-in-place concrete. Cast-in-place concrete often results in higher carbon emissions due to on-site production processes, increased water usage, and formwork waste. The ability to reuse precast forms and reduce transportation emissions through optimized logistics further enhances the sustainability profile of precast concrete over cast-in-place options.

Precast vs cast-in-place concrete Infographic

libmatt.com

libmatt.com