Fiber mesh provides enhanced crack resistance and durability for concrete surfaces by distributing stresses throughout the material, making it ideal for flooring and slabs. Wire mesh offers greater structural support and tensile strength, commonly used in large-scale construction projects to reinforce foundations and walls effectively.

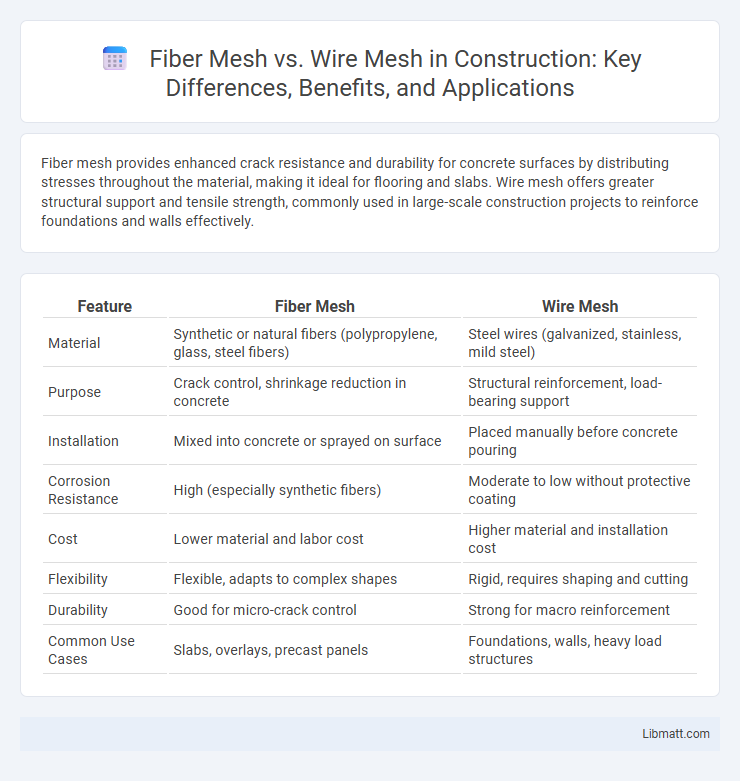

Table of Comparison

| Feature | Fiber Mesh | Wire Mesh |

|---|---|---|

| Material | Synthetic or natural fibers (polypropylene, glass, steel fibers) | Steel wires (galvanized, stainless, mild steel) |

| Purpose | Crack control, shrinkage reduction in concrete | Structural reinforcement, load-bearing support |

| Installation | Mixed into concrete or sprayed on surface | Placed manually before concrete pouring |

| Corrosion Resistance | High (especially synthetic fibers) | Moderate to low without protective coating |

| Cost | Lower material and labor cost | Higher material and installation cost |

| Flexibility | Flexible, adapts to complex shapes | Rigid, requires shaping and cutting |

| Durability | Good for micro-crack control | Strong for macro reinforcement |

| Common Use Cases | Slabs, overlays, precast panels | Foundations, walls, heavy load structures |

Introduction to Fiber Mesh and Wire Mesh

Fiber mesh consists of synthetic or natural fibers embedded in concrete to enhance tensile strength and reduce cracking, while wire mesh is a grid of steel wires used for structural reinforcement in concrete slabs and walls. Fiber mesh offers improved resistance to shrinkage and impact, providing a more uniform distribution of stress throughout the concrete. Wire mesh provides strong load-bearing capacity, commonly used in heavy-duty applications requiring substantial mechanical support.

Composition and Material Differences

Fiber mesh consists of synthetic fibers such as polypropylene or glass, offering enhanced flexibility and corrosion resistance, while wire mesh is made from steel wires--either galvanized, stainless, or carbon steel--providing superior tensile strength and rigidity. Your choice depends on the specific application, with fiber mesh improving crack control in concrete and wire mesh delivering structural reinforcement. Understanding these material differences helps optimize durability and performance in construction projects.

Strength and Durability Comparison

Fiber mesh provides enhanced tensile strength and crack resistance in concrete by distributing loads evenly, making it highly durable against shrinking and settling. Wire mesh offers superior load-bearing capacity and impact resistance due to its rigid steel composition, ensuring long-term structural support. Your choice between fiber mesh and wire mesh should depend on specific strength requirements and environmental exposure for optimal durability.

Installation Process and Techniques

Fiber mesh installation involves evenly distributing synthetic fibers within the concrete mix before pouring, simplifying the process by eliminating the need for precise positioning. Wire mesh requires careful placement and securing within the formwork to ensure proper reinforcement alignment and avoid shifting during the pour. Your choice impacts installation time and labor costs, with fiber mesh generally offering faster setup and reduced handling complexities compared to traditional wire mesh.

Cost Analysis: Fiber Mesh vs. Wire Mesh

Fiber mesh generally offers a lower upfront cost compared to wire mesh due to reduced material and installation expenses, making it a cost-effective option for large-scale concrete projects. Wire mesh, while typically more expensive initially, provides superior tensile strength and durability, potentially lowering long-term maintenance and repair costs. Project-specific factors such as concrete thickness, load requirements, and environmental conditions ultimately influence the overall cost-efficiency between fiber mesh and wire mesh reinforcement.

Crack Resistance and Flexibility

Fiber mesh offers superior crack resistance due to its ability to distribute stress evenly throughout the concrete, reducing the formation and propagation of cracks. Wire mesh, while providing structural support, is less flexible and may concentrate stress points, making it more prone to crack development. For your construction project, choosing fiber mesh can enhance durability by maintaining flexibility and minimizing crack risks in the concrete.

Application Suitability in Construction

Fiber mesh enhances concrete durability by reducing cracking and shrinkage, making it ideal for flatwork like slabs, pavements, and driveways. Wire mesh offers superior tensile strength and load distribution, suitable for structural components such as beams, columns, and walls. Your choice depends on construction requirements, with fiber mesh preferred for surface reinforcement and wire mesh for heavy-load bearing applications.

Environmental Impact and Sustainability

Fiber mesh offers a lower environmental impact compared to wire mesh due to its production from synthetic or natural fibers, which require less energy and generate fewer carbon emissions. Wire mesh involves mining and metal processing, contributing to higher resource depletion and pollution levels. Choosing fiber mesh supports sustainability by reducing landfill waste and promoting the use of renewable materials, aligning with your eco-friendly construction goals.

Maintenance and Longevity Factors

Fiber mesh requires less maintenance than wire mesh due to its resistance to corrosion, rust, and environmental degradation, making it ideal for long-term durability in concrete reinforcement. Wire mesh can suffer from rust and corrosion if not properly coated or maintained, potentially shortening its lifespan and increasing repair costs. Your choice should consider the environmental exposure and maintenance resources available to ensure optimal longevity and performance.

Choosing the Right Mesh for Your Project

Fiber mesh offers superior crack resistance and corrosion durability, making it ideal for slab-on-grade projects and concrete repair applications. Wire mesh provides enhanced structural reinforcement and load distribution, suited for heavy-duty construction such as foundations and industrial floors. Selecting the right mesh depends on factors like project load requirements, environmental conditions, and specific structural demands to maximize concrete performance and longevity.

Fiber mesh vs wire mesh Infographic

libmatt.com

libmatt.com