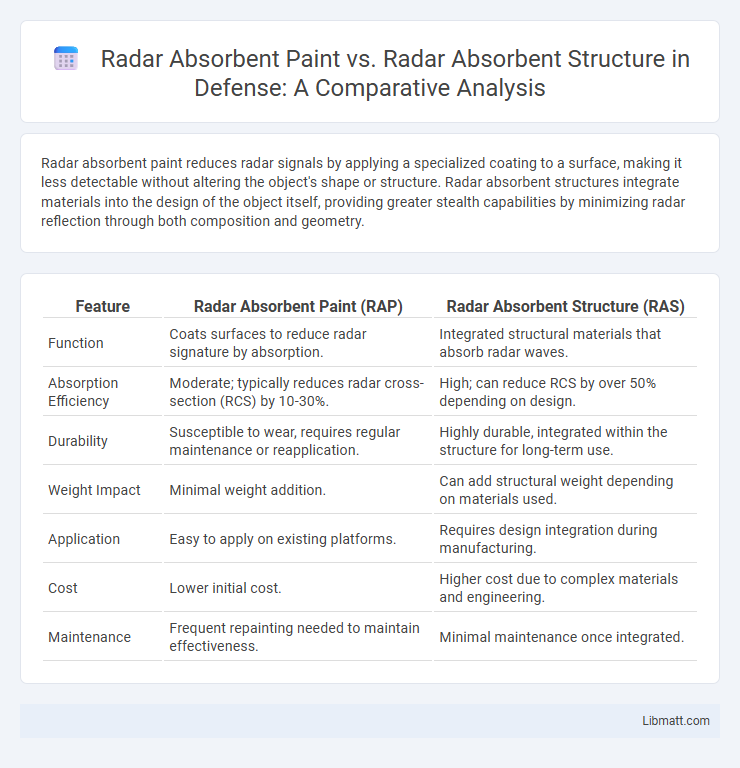

Radar absorbent paint reduces radar signals by applying a specialized coating to a surface, making it less detectable without altering the object's shape or structure. Radar absorbent structures integrate materials into the design of the object itself, providing greater stealth capabilities by minimizing radar reflection through both composition and geometry.

Table of Comparison

| Feature | Radar Absorbent Paint (RAP) | Radar Absorbent Structure (RAS) |

|---|---|---|

| Function | Coats surfaces to reduce radar signature by absorption. | Integrated structural materials that absorb radar waves. |

| Absorption Efficiency | Moderate; typically reduces radar cross-section (RCS) by 10-30%. | High; can reduce RCS by over 50% depending on design. |

| Durability | Susceptible to wear, requires regular maintenance or reapplication. | Highly durable, integrated within the structure for long-term use. |

| Weight Impact | Minimal weight addition. | Can add structural weight depending on materials used. |

| Application | Easy to apply on existing platforms. | Requires design integration during manufacturing. |

| Cost | Lower initial cost. | Higher cost due to complex materials and engineering. |

| Maintenance | Frequent repainting needed to maintain effectiveness. | Minimal maintenance once integrated. |

Introduction to Radar Absorbent Technologies

Radar absorbent paint uses specialized coatings infused with carbon or ferrite particles to reduce radar wave reflection on surfaces. Radar absorbent structures integrate materials like foam or honeycomb composites within the object's design to scatter and absorb radar signals more effectively. Your choice between these technologies depends on factors such as application type, weight constraints, and required stealth performance.

Understanding Radar Absorbent Paint

Radar absorbent paint (RAP) consists of specialized materials that reduce radar signal reflection by converting electromagnetic waves into heat, offering a lightweight and flexible stealth solution. Unlike radar absorbent structures (RAS), which integrate radar-absorbing materials directly into the physical design of an object, RAP can be easily applied to various surfaces without altering structural integrity. Understanding radar absorbent paint helps you select the most practical and cost-effective method for minimizing radar detection in diverse applications.

Exploring Radar Absorbent Structures

Radar absorbent structures (RAS) offer enhanced stealth capabilities by integrating radar absorbent materials directly into the design of surfaces, unlike radar absorbent paint which only provides a superficial layer of absorption. RAS optimizes electromagnetic wave attenuation through engineered geometries and material layering, significantly reducing radar cross-section beyond the capabilities of traditional coatings. The inherent structural integration of RAS improves durability and effectiveness in complex operational environments compared to radar absorbent paint, which can degrade under harsh conditions.

Key Differences Between Paint and Structural Solutions

Radar absorbent paint primarily offers a thin, lightweight coating that reduces radar cross-section by absorbing incident electromagnetic waves, making it suitable for retrofitting existing surfaces. Radar absorbent structures integrate absorbing materials directly into the composite or design of the object itself, providing deeper and more consistent attenuation across a broader frequency range. Paint solutions deliver ease of application and flexibility, whereas structural solutions offer enhanced durability and superior stealth performance through material engineering.

Material Composition and Engineering

Radar absorbent paint typically consists of polymer-based materials infused with magnetic or dielectric fillers such as carbon black, ferrites, or iron oxides, engineered to attenuate electromagnetic waves through surface absorption and impedance matching. Radar absorbent structures employ engineered composites or metamaterials integrating carbon fiber, conductive polymers, or magnetic inclusions arranged in specific geometric patterns to achieve volumetric absorption and scattering reduction via material anisotropy and multi-layer interference. The design and material composition of absorbent structures allow for enhanced broadband radar cross-section reduction compared to the primarily surface-level performance of radar absorbent paint.

Effectiveness in Reducing Radar Cross Section

Radar absorbent paint (RAP) provides moderate reduction in radar cross section (RCS) by coating surfaces to absorb radar waves, typically offering effectiveness in specific frequency ranges and angles of incidence. Radar absorbent structures (RAS), with integrated materials and geometrical design, achieve superior RCS reduction by disrupting and attenuating radar signals more comprehensively across wider frequency bands and diverse angles. The enhanced performance of RAS over RAP results from their optimized composition and shape, significantly improving stealth capabilities in military and aerospace applications.

Application Methods and Use Cases

Radar absorbent paint is typically applied as a coating on surfaces, providing a thin, uniform layer that reduces radar signal reflection on various materials like aircraft or vehicles. Radar absorbent structures, in contrast, involve integrating special materials or geometries directly into the physical design, offering more effective and durable stealth capabilities for larger applications such as military vessels or aerospace components. Your choice depends on the required stealth level, environmental conditions, and the complexity of the target's shape.

Durability and Maintenance Considerations

Radar absorbent paint typically offers ease of application and reapplication but may degrade faster under harsh environmental conditions, requiring more frequent maintenance to retain its radar-absorbing properties. In contrast, radar absorbent structures integrate materials such as carbon composites or specialized coatings within the design, providing enhanced durability and longer service life with minimal upkeep. Selecting between paint and structural solutions depends on the operational environment and maintenance capabilities, with structures favoring longevity and paints offering flexibility.

Cost and Performance Comparison

Radar absorbent paint offers a cost-effective solution with easier application and maintenance, suitable for variable surfaces but generally provides moderate absorption performance. Radar absorbent structures, while more expensive due to complex materials and manufacturing processes, deliver superior radar wave attenuation and durability, ideal for critical stealth applications. Choosing between them depends on budget constraints and required stealth effectiveness, with structures favored for high-performance scenarios and paints for economical, versatile coverage.

Future Trends in Stealth Technology

Radar absorbent paint and radar absorbent structures represent two critical advancements in stealth technology, where future trends emphasize integration with adaptive materials and smart coatings for enhanced electromagnetic wave manipulation. Research focuses on nanomaterial-infused radar absorbent paint that can dynamically change its absorption properties, while radar absorbent structures are evolving to include metamaterials with tunable features for multi-band stealth capabilities. Your ability to leverage these innovations will define the next generation of stealth platforms, combining surface treatments and structural design for optimal radar signature reduction.

radar absorbent paint vs radar absorbent structure Infographic

libmatt.com

libmatt.com