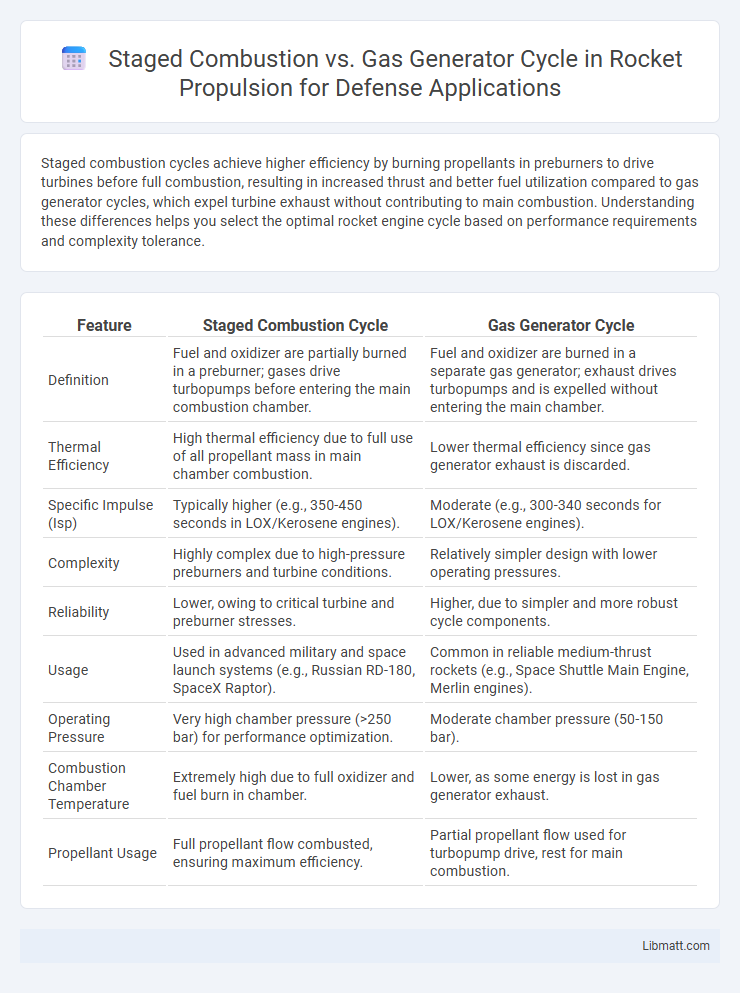

Staged combustion cycles achieve higher efficiency by burning propellants in preburners to drive turbines before full combustion, resulting in increased thrust and better fuel utilization compared to gas generator cycles, which expel turbine exhaust without contributing to main combustion. Understanding these differences helps you select the optimal rocket engine cycle based on performance requirements and complexity tolerance.

Table of Comparison

| Feature | Staged Combustion Cycle | Gas Generator Cycle |

|---|---|---|

| Definition | Fuel and oxidizer are partially burned in a preburner; gases drive turbopumps before entering the main combustion chamber. | Fuel and oxidizer are burned in a separate gas generator; exhaust drives turbopumps and is expelled without entering the main chamber. |

| Thermal Efficiency | High thermal efficiency due to full use of all propellant mass in main chamber combustion. | Lower thermal efficiency since gas generator exhaust is discarded. |

| Specific Impulse (Isp) | Typically higher (e.g., 350-450 seconds in LOX/Kerosene engines). | Moderate (e.g., 300-340 seconds for LOX/Kerosene engines). |

| Complexity | Highly complex due to high-pressure preburners and turbine conditions. | Relatively simpler design with lower operating pressures. |

| Reliability | Lower, owing to critical turbine and preburner stresses. | Higher, due to simpler and more robust cycle components. |

| Usage | Used in advanced military and space launch systems (e.g., Russian RD-180, SpaceX Raptor). | Common in reliable medium-thrust rockets (e.g., Space Shuttle Main Engine, Merlin engines). |

| Operating Pressure | Very high chamber pressure (>250 bar) for performance optimization. | Moderate chamber pressure (50-150 bar). |

| Combustion Chamber Temperature | Extremely high due to full oxidizer and fuel burn in chamber. | Lower, as some energy is lost in gas generator exhaust. |

| Propellant Usage | Full propellant flow combusted, ensuring maximum efficiency. | Partial propellant flow used for turbopump drive, rest for main combustion. |

Introduction to Rocket Engine Cycles

Rocket engine cycles determine how propellants are fed into the combustion chamber, with staged combustion and gas generator cycles being two primary methods. Staged combustion cycles utilize preburners to partially burn propellant, creating hot gases that drive turbines before entering the main combustion chamber, resulting in higher efficiency and performance. Gas generator cycles, meanwhile, burn some propellant separately to power turbines, venting the exhaust overboard, which simplifies design but sacrifices some efficiency compared to staged combustion.

Overview of Staged Combustion Cycle

The staged combustion cycle efficiently burns propellant in pre-burners to drive turbines before feeding hot gases into the main combustion chamber, maximizing thrust and overall engine performance. It achieves higher specific impulse by utilizing all propellants in a closed cycle, reducing waste and improving fuel efficiency compared to gas generator cycles. Your rocket engine benefits from increased power and reliability through this advanced thermodynamic process.

Overview of Gas Generator Cycle

The gas generator cycle powers the rocket engine by burning a small portion of propellant in a separate gas generator, which drives the turbine before exhausting the gases overboard, ensuring cooler turbine operation compared to staged combustion. This cycle offers simpler design and lower development cost, making it common in many reliable rocket engines such as the SpaceX Merlin or the RD-180. Your rocket's performance benefits from its robustness and ease of maintenance, although it sacrifices some overall efficiency relative to staged combustion, where all propellant passes through the turbines.

Key Differences Between Staged Combustion and Gas Generator

Staged combustion and gas generator cycles differ primarily in their handling of propellant efficiency and turbine operation. Staged combustion recycles all propellant through the main combustion chamber, offering higher specific impulse and fuel efficiency, while the gas generator cycle expels some propellant to drive the turbine, resulting in lower efficiency but simpler design. Your choice between these cycles affects engine complexity, performance, and maintenance requirements.

Efficiency Comparison: Staged Combustion vs Gas Generator

Staged combustion cycle rockets achieve higher efficiency by utilizing all propellant components in the combustion process, resulting in increased specific impulse compared to gas generator cycles, which expel turbine exhaust separately and lose some energy. The closed-cycle design of staged combustion enables more complete fuel combustion and higher chamber pressures, contributing to better performance metrics. Gas generator cycles offer simplicity and reliability but at the cost of lower propellant utilization and reduced overall engine efficiency.

Complexity and Engineering Challenges

The staged combustion cycle exhibits higher complexity and engineering challenges due to its requirement for preburners to operate at extremely high pressures and temperatures, demanding advanced materials and precision in component design. In contrast, the gas generator cycle is simpler, as it dumps turbine exhaust overboard, reducing thermal and mechanical stress on the turbopumps but resulting in lower overall efficiency. The intricate balance of oxidizer-rich or fuel-rich preburners in staged combustion engines significantly increases development risks and manufacturing costs compared to the straightforward, robust design of gas generator systems.

Performance Implications for Rocket Applications

Staged combustion cycle engines achieve higher efficiency by burning propellant in preburners, resulting in greater specific impulse (Isp) and improved thrust-to-weight ratio compared to gas generator engines that vent unused propellant. Gas generator cycles tend to have simpler designs and higher reliability but sacrifice overall performance due to propellant loss in the gas generator exhaust. Your rocket's mission requirements and performance goals will determine which cycle offers the optimal balance between efficiency and complexity.

Notable Engines Using Staged Combustion Cycle

Notable engines using the staged combustion cycle include the Russian RD-180 and the SpaceX Raptor, both renowned for their high efficiency and thrust-to-weight ratios. This cycle enables near-complete propellant combustion by routing fuel or oxidizer through the preburner before entering the combustion chamber, resulting in higher performance compared to the gas generator cycle used in engines like the Rocketdyne F-1. Understanding these distinctions helps optimize your rocket engine design by leveraging staged combustion's superior fuel economy and thrust capabilities.

Notable Engines Using Gas Generator Cycle

Notable engines using the gas generator cycle include the Rocketdyne F-1, Saturn V's first-stage engine, and the SpaceX Merlin series, both known for high reliability and thrust. This cycle operates by diverting some propellant to drive the turbopumps, resulting in simpler design but lower efficiency compared to staged combustion engines. Your rocket's propulsion system may favor this cycle for its proven performance in heavy-lift launch vehicles.

Choosing the Right Cycle: Factors and Future Trends

Selecting between staged combustion and gas generator cycles depends on mission requirements such as specific impulse, thrust-to-weight ratio, and engine complexity. Staged combustion offers higher efficiency and performance ideal for reusable launch vehicles, while gas generator cycles provide simpler design and reliability suited for expendable rockets. Future trends emphasize developing oxygen-rich staged combustion engines to enhance performance and sustainability in next-generation heavy-lift launch systems.

staged combustion vs gas generator cycle (rockets) Infographic

libmatt.com

libmatt.com