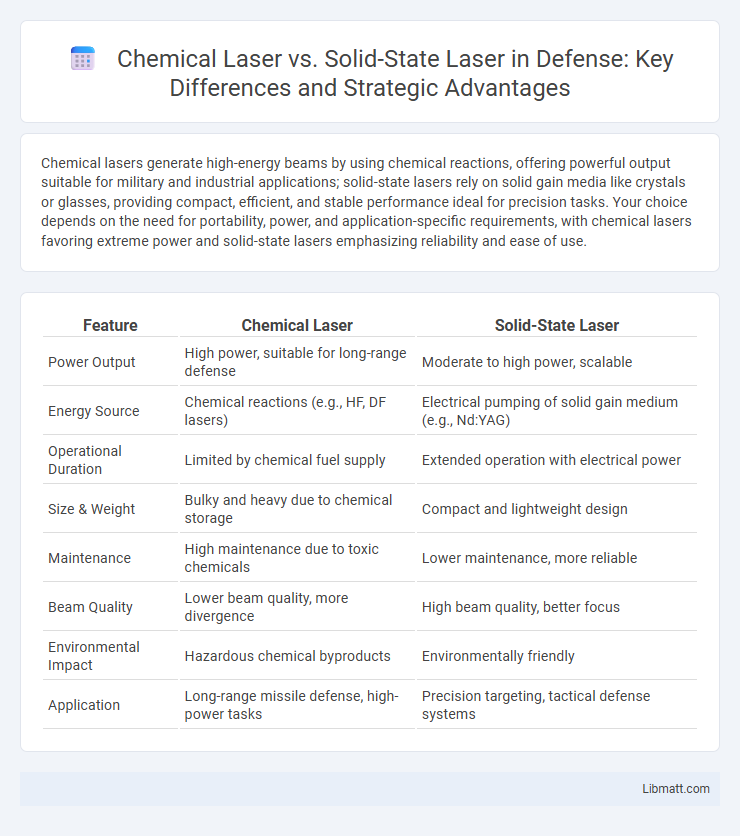

Chemical lasers generate high-energy beams by using chemical reactions, offering powerful output suitable for military and industrial applications; solid-state lasers rely on solid gain media like crystals or glasses, providing compact, efficient, and stable performance ideal for precision tasks. Your choice depends on the need for portability, power, and application-specific requirements, with chemical lasers favoring extreme power and solid-state lasers emphasizing reliability and ease of use.

Table of Comparison

| Feature | Chemical Laser | Solid-State Laser |

|---|---|---|

| Power Output | High power, suitable for long-range defense | Moderate to high power, scalable |

| Energy Source | Chemical reactions (e.g., HF, DF lasers) | Electrical pumping of solid gain medium (e.g., Nd:YAG) |

| Operational Duration | Limited by chemical fuel supply | Extended operation with electrical power |

| Size & Weight | Bulky and heavy due to chemical storage | Compact and lightweight design |

| Maintenance | High maintenance due to toxic chemicals | Lower maintenance, more reliable |

| Beam Quality | Lower beam quality, more divergence | High beam quality, better focus |

| Environmental Impact | Hazardous chemical byproducts | Environmentally friendly |

| Application | Long-range missile defense, high-power tasks | Precision targeting, tactical defense systems |

Introduction to Chemical and Solid-State Lasers

Chemical lasers generate laser beams through chemical reactions that release energy, typically producing high-power output ideal for military and industrial applications. Solid-state lasers employ a solid gain medium such as crystals or glasses doped with rare-earth ions, offering reliable, compact, and efficient laser sources widely used in medicine and manufacturing. The fundamental difference lies in their energy source and medium, with chemical lasers relying on chemical energy and solid-state lasers using optical pumping of solid materials.

Fundamental Working Principles

Chemical lasers generate energy through a chemical reaction between reactive substances, producing a population inversion and emitting coherent light, often resulting in high power output suitable for military and industrial applications. Solid-state lasers rely on a solid gain medium, such as doped crystals or glasses, excited by optical pumping to achieve population inversion and stimulated emission, offering improved stability and compactness. Understanding these fundamental working principles helps you choose the laser type that best fits your application's power needs and operational environment.

Key Differences in Laser Generation

Chemical lasers generate light through a chemical reaction, producing high-power continuous-wave output primarily used in military and industrial applications. Solid-state lasers rely on a solid gain medium, such as doped crystals or glasses, energized by electrical pumping or flash lamps, offering compact size and stability. The chemical laser's energy conversion efficiency and output power typically surpass that of solid-state lasers, which excel in precision and maintenance ease.

Efficiency and Power Output Comparison

Chemical lasers exhibit superior power output, often reaching megawatt levels due to their chemical energy sources, making them highly effective for high-energy applications such as military and industrial cutting. Solid-state lasers offer improved efficiency through advanced diode pumping and thermal management techniques, enabling higher beam quality and stability with power outputs typically in the kilowatt range. The efficiency of chemical lasers ranges from 20% to 30%, while solid-state lasers can achieve values above 30%, balancing power output and operational sustainability.

Operational Requirements and Complexity

Chemical lasers require complex infrastructure involving the handling and storage of hazardous chemicals, specialized cooling systems, and precise reaction control, making their operational requirements significantly demanding. Solid-state lasers operate with solid gain media such as crystals or glasses, simplifying maintenance and reducing the need for extensive support systems, resulting in lower operational complexity. The robustness and compactness of solid-state lasers contribute to easier deployment and integration in various applications compared to the intricate setups required for chemical lasers.

Safety and Environmental Concerns

Chemical lasers often pose greater safety and environmental risks due to the use of hazardous chemicals and the production of toxic exhaust, requiring stringent handling and disposal measures. Solid-state lasers, by contrast, operate with solid gain media and do not rely on volatile chemicals, minimizing hazardous waste and reducing the environmental impact. When considering your laser application, solid-state lasers typically offer a safer and more eco-friendly option.

Applications in Industry and Defense

Chemical lasers, known for their high power output and ability to operate continuously, are primarily used in military applications such as missile defense, target designation, and directed-energy weapons due to their efficiency over long distances. Solid-state lasers, valued for their compact size, reliability, and lower operational costs, find extensive use in industrial applications including materials processing, precision cutting, welding, and medical procedures. Both technologies serve critical roles in defense and industry, with chemical lasers favored in large-scale military operations and solid-state lasers preferred for versatile, fine-scale industrial tasks.

Cost Considerations and Scalability

Chemical lasers typically involve higher operational costs due to the continuous need for chemical fuel and complex handling systems, limiting their scalability for widespread commercial use. Solid-state lasers benefit from lower maintenance expenses and more straightforward energy requirements, enabling easier scalability and cost-effective mass production. The choice between chemical and solid-state lasers often hinges on balancing initial investment and long-term operational cost efficiencies.

Recent Technological Advancements

Recent technological advancements in chemical lasers have focused on enhancing fuel efficiency and reducing hazardous byproducts through the development of cleaner chemical reactions and novel propellant mixtures. Solid-state lasers have seen significant improvements in power scaling and beam quality, driven by innovations in diode pumping technology and advanced thermal management systems using novel crystalline materials. Integration of adaptive optics and real-time beam control further distinguishes solid-state lasers by enabling precise targeting and increased operational flexibility in diverse applications.

Future Prospects and Emerging Trends

Chemical lasers, known for high energy outputs in missile defense, are increasingly focused on improving fuel efficiency and reducing toxic byproducts to enhance operational viability. Solid-state lasers exhibit significant advancements in power scaling, beam quality, and compactness, driving their adoption in defense and industrial applications with greater energy efficiency and lower maintenance. Emerging trends highlight hybrid systems combining chemical and solid-state technologies to leverage high power with improved sustainability and deployment flexibility.

chemical laser vs solid-state laser Infographic

libmatt.com

libmatt.com