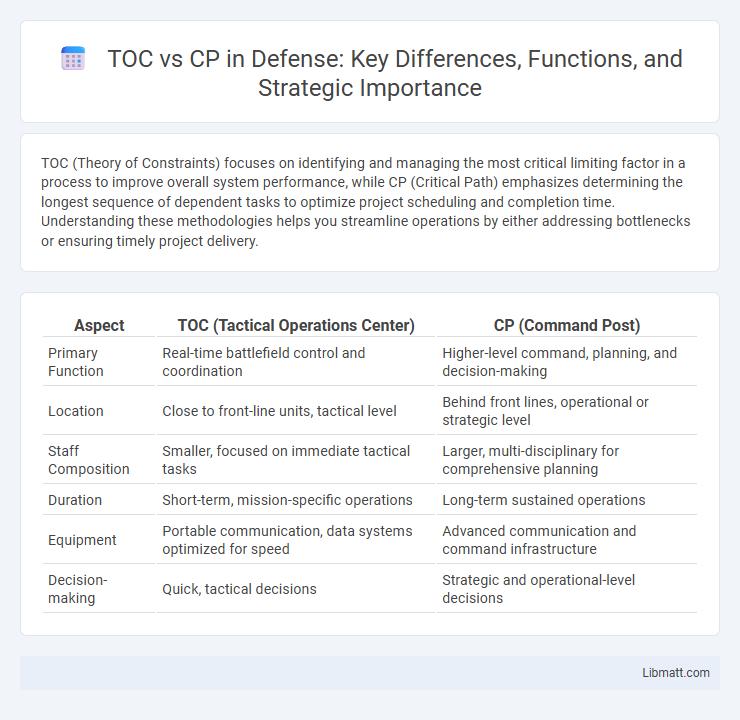

TOC (Theory of Constraints) focuses on identifying and managing the most critical limiting factor in a process to improve overall system performance, while CP (Critical Path) emphasizes determining the longest sequence of dependent tasks to optimize project scheduling and completion time. Understanding these methodologies helps you streamline operations by either addressing bottlenecks or ensuring timely project delivery.

Table of Comparison

| Aspect | TOC (Tactical Operations Center) | CP (Command Post) |

|---|---|---|

| Primary Function | Real-time battlefield control and coordination | Higher-level command, planning, and decision-making |

| Location | Close to front-line units, tactical level | Behind front lines, operational or strategic level |

| Staff Composition | Smaller, focused on immediate tactical tasks | Larger, multi-disciplinary for comprehensive planning |

| Duration | Short-term, mission-specific operations | Long-term sustained operations |

| Equipment | Portable communication, data systems optimized for speed | Advanced communication and command infrastructure |

| Decision-making | Quick, tactical decisions | Strategic and operational-level decisions |

Understanding TOC and CP: Definitions and Core Principles

The Theory of Constraints (TOC) identifies the most critical limiting factor in a process and systematically improves it to increase overall performance. Critical Path (CP) method maps out the longest sequence of dependent tasks to determine the minimum project duration and identify scheduling priorities. Both frameworks emphasize optimizing workflows but differ in focus: TOC targets bottleneck resolution while CP focuses on timeline management.

Key Differences Between TOC and CP

The Theory of Constraints (TOC) emphasizes identifying and eliminating the single most critical bottleneck in a process to improve overall system throughput, while Critical Path (CP) analysis focuses on determining the longest sequence of dependent tasks to establish project duration. TOC targets process optimization by managing constraints to increase flow and reduce cycle time, whereas CP centers on scheduling and time management to ensure project completion within deadlines. Both methodologies aid in performance improvement, but TOC is constraint-driven for operational efficiency, and CP is time-driven for project timeline control.

Historical Development of TOC and CP

The Theory of Constraints (TOC), developed by Eliyahu M. Goldratt in the early 1980s, originated from his work on manufacturing optimization and was formalized in his book "The Goal." Critical Path (CP) method emerged in the late 1950s through DuPont and Remington Rand, initially designed for project scheduling in complex aerospace and construction projects. While TOC focuses on identifying and managing system bottlenecks to improve throughput, CP emphasizes the identification of the longest sequence of dependent tasks to optimize project completion time.

Applications of TOC in Modern Industries

Theory of Constraints (TOC) is widely applied in modern industries such as manufacturing, supply chain management, and project management to identify and alleviate bottlenecks that restrict overall system performance. By focusing on the constraint, TOC enables businesses to optimize throughput, reduce lead times, and enhance resource allocation, leading to significant improvements in productivity and profitability. Your organization can leverage TOC principles to streamline operations and achieve sustainable competitive advantages in dynamic market environments.

Practical Uses of CP Across Sectors

Constraint Programming (CP) is widely applied in sectors like logistics for optimizing scheduling and resource allocation, manufacturing for production planning, and finance for portfolio management to handle complex constraints efficiently. In contrast to Theory of Constraints (TOC), CP provides precise computational methods to solve combinatorial problems, enabling real-time decision-making in supply chain management and energy distribution. Its flexibility and scalability make CP ideal for custom problem-solving across industries requiring optimized operational workflows.

Advantages and Limitations of TOC

The Theory of Constraints (TOC) offers significant advantages by identifying the most critical bottleneck in a process, enabling targeted improvements that maximize throughput and optimize resource allocation. However, TOC's limitation lies in its narrow focus on a single constraint at a time, which can overlook other limiting factors in complex systems, potentially leading to suboptimal overall performance. While TOC drives rapid, focused gains, it may require integration with broader methodologies like Critical Path (CP) analysis for comprehensive project scheduling and resource management.

Strengths and Weaknesses of CP

Critical Path (CP) analysis excels in identifying the longest sequence of dependent tasks, ensuring project completion on time by highlighting scheduling constraints. Its strength lies in clear visualization of task dependencies and float times, but it may struggle with complex resource allocation and dynamic changes. Your project benefits from CP's precise timeline focus, although relying solely on it can overlook flexibility and critical bottlenecks addressed better by Theory of Constraints (TOC).

Real-World Case Studies: TOC vs CP

Real-world case studies comparing Theory of Constraints (TOC) and Critical Path (CP) methods reveal distinct advantages in project management efficiency and resource optimization. TOC focuses on identifying and managing bottlenecks to accelerate throughput, while CP emphasizes task sequencing to reduce overall project duration. Your choice between TOC's constraint-driven approach and CP's timeline-based planning depends on the specific challenges and objectives within your project environment.

Choosing Between TOC and CP: Factors to Consider

Choosing between Total Organic Carbon (TOC) and Conductivity Purity (CP) depends on the specific water quality parameters required for your application. TOC analysis is essential for monitoring organic contaminants, providing detailed insights into carbon-based impurities critical for pharmaceutical and semiconductor industries. CP measurement offers rapid detection of ionic impurities, making it ideal for processes where electrical conductivity correlates directly with purity levels, such as ultrapure water systems and boiler feedwater monitoring.

Future Trends in TOC and CP Implementation

Future trends in the implementation of Theory of Constraints (TOC) and Critical Path (CP) methodologies emphasize integration with advanced digital tools such as AI-driven project management software, enhancing real-time bottleneck identification and resolution in TOC, while optimizing CP scheduling accuracy. Lean construction and Agile methodologies are increasingly combined with TOC and CP to improve flexibility and responsiveness in dynamic project environments. Data analytics and machine learning advancements enable predictive modeling for constraint management and path optimization, driving more efficient resource allocation and project delivery timelines.

TOC vs CP Infographic

libmatt.com

libmatt.com