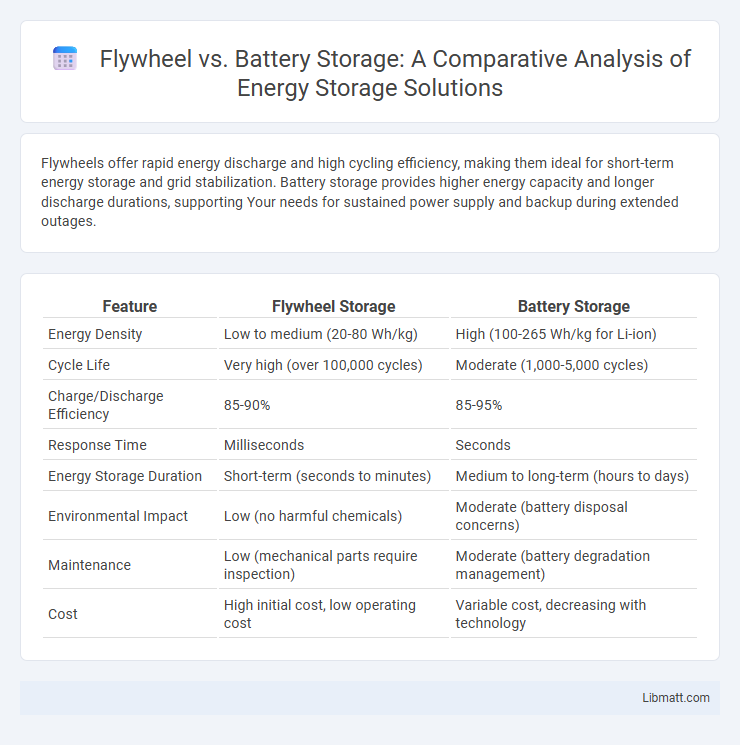

Flywheels offer rapid energy discharge and high cycling efficiency, making them ideal for short-term energy storage and grid stabilization. Battery storage provides higher energy capacity and longer discharge durations, supporting Your needs for sustained power supply and backup during extended outages.

Table of Comparison

| Feature | Flywheel Storage | Battery Storage |

|---|---|---|

| Energy Density | Low to medium (20-80 Wh/kg) | High (100-265 Wh/kg for Li-ion) |

| Cycle Life | Very high (over 100,000 cycles) | Moderate (1,000-5,000 cycles) |

| Charge/Discharge Efficiency | 85-90% | 85-95% |

| Response Time | Milliseconds | Seconds |

| Energy Storage Duration | Short-term (seconds to minutes) | Medium to long-term (hours to days) |

| Environmental Impact | Low (no harmful chemicals) | Moderate (battery disposal concerns) |

| Maintenance | Low (mechanical parts require inspection) | Moderate (battery degradation management) |

| Cost | High initial cost, low operating cost | Variable cost, decreasing with technology |

Introduction to Energy Storage Technologies

Flywheels store energy mechanically by spinning a rotor at high speeds, offering rapid response and high power output ideal for grid stabilization. Battery storage systems use electrochemical processes to store and discharge energy, providing longer-duration energy supply and scalability for various applications. Understanding the differences in efficiency, lifespan, and cost helps you choose the right energy storage technology for your specific needs.

Understanding Flywheel Energy Storage

Flywheel energy storage systems store kinetic energy by accelerating a rotor to high speeds and maintaining its momentum, enabling rapid energy release and recharge cycles. Unlike battery storage, flywheels offer longer operational lifespans, minimal degradation, and high power density, making them ideal for short-term energy buffering and grid frequency regulation. Their mechanical nature allows for efficient and fast response times, supporting applications that demand quick bursts of energy and frequent cycling.

Overview of Battery Storage Systems

Battery storage systems store electrical energy chemically using cells composed of anodes, cathodes, and electrolytes, delivering power through controlled chemical reactions. Lithium-ion batteries dominate the market due to high energy density, efficiency, and scalability for applications ranging from grid support to renewable integration. Advances in battery management systems (BMS) and decreasing costs enhance grid stability, load shifting, and peak demand management compared to other energy storage technologies like flywheels.

Key Differences Between Flywheels and Batteries

Flywheels store energy mechanically by spinning a rotor at high speeds, while batteries store energy chemically through electrochemical reactions. Flywheels excel in delivering short bursts of high power with rapid charge and discharge cycles, whereas batteries provide longer-term energy storage with higher energy density. The lifespan of flywheels is typically longer with minimal degradation, contrasting with batteries that face capacity loss over time due to chemical wear.

Efficiency and Performance Comparison

Flywheel energy storage systems typically offer round-trip efficiencies between 85% and 90%, while lithium-ion battery storage achieves efficiencies around 90% to 95%, making batteries slightly more efficient in energy retention. Flywheels excel in high power density and rapid charge-discharge cycles with low degradation over millions of cycles, providing superior performance for short-duration, high-frequency applications. Batteries, while offering longer energy storage durations and greater energy density, generally experience faster capacity fade and require more maintenance over time compared to the mechanical robustness of flywheels.

Durability and Lifespan Analysis

Flywheels offer exceptional durability with lifespan often exceeding 20 years and can handle more than one million charge-discharge cycles, making them ideal for high-cycle applications. Battery storage systems, particularly lithium-ion, typically last 5 to 15 years with 500 to 3,000 cycles, but their performance diminishes over time due to capacity degradation. Your choice depends on whether you prioritize long-term durability and cycle life (flywheels) or higher energy density and storage duration (batteries).

Environmental Impact and Sustainability

Flywheel energy storage offers longer lifecycle durability and lower environmental impact due to minimal use of hazardous materials compared to battery storage, which often relies on finite resources like lithium and cobalt. Battery systems present challenges in recycling and disposal, contributing to environmental pollution and resource depletion. Flywheels provide sustainable energy storage with reduced carbon footprint and better recyclability, making them a greener alternative in the transition to renewable energy.

Cost Factors and Economic Considerations

Flywheel storage systems typically have higher upfront capital costs but lower operating and maintenance expenses compared to battery storage. Battery storage solutions, such as lithium-ion, often involve significant degradation and replacement costs impacting long-term economic viability. Lifecycle cost analysis reveals that flywheels offer cost-effectiveness for applications requiring high cycle throughput and rapid response times, while batteries excel in energy-intensive, longer-duration storage scenarios.

Applications and Use Cases

Flywheel energy storage excels in applications requiring rapid charge and discharge cycles, such as frequency regulation, uninterruptible power supply (UPS), and short-term grid stabilization. Battery storage systems offer versatile use cases including long-duration energy backup, renewable energy integration, electric vehicle support, and peak load shaving. In industrial settings, flywheels provide high power density and longevity for frequent cycling, while batteries are preferred for their higher energy density and scalability in residential and utility-scale projects.

Future Trends in Energy Storage Solutions

Flywheel and battery storage technologies are evolving rapidly to address grid stability and renewable integration challenges, with future trends emphasizing higher energy density, longer cycle life, and reduced costs. Emerging innovations in flywheel systems focus on magnetic bearings and vacuum enclosures to minimize friction losses, while battery storage advancements highlight solid-state chemistries and improved thermal management. These developments aim to enhance scalability, efficiency, and environmental sustainability in large-scale energy storage deployments.

Flywheel vs Battery Storage Infographic

libmatt.com

libmatt.com