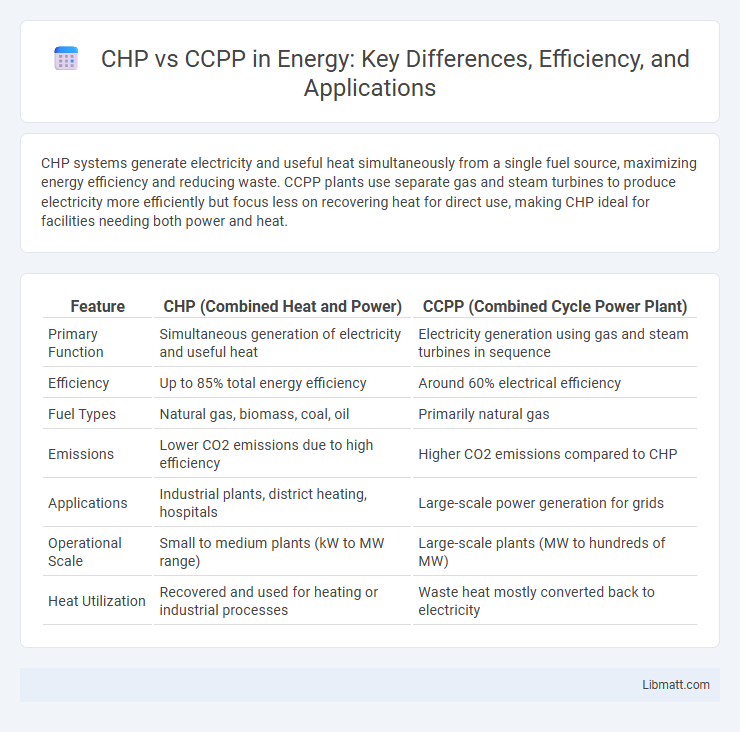

CHP systems generate electricity and useful heat simultaneously from a single fuel source, maximizing energy efficiency and reducing waste. CCPP plants use separate gas and steam turbines to produce electricity more efficiently but focus less on recovering heat for direct use, making CHP ideal for facilities needing both power and heat.

Table of Comparison

| Feature | CHP (Combined Heat and Power) | CCPP (Combined Cycle Power Plant) |

|---|---|---|

| Primary Function | Simultaneous generation of electricity and useful heat | Electricity generation using gas and steam turbines in sequence |

| Efficiency | Up to 85% total energy efficiency | Around 60% electrical efficiency |

| Fuel Types | Natural gas, biomass, coal, oil | Primarily natural gas |

| Emissions | Lower CO2 emissions due to high efficiency | Higher CO2 emissions compared to CHP |

| Applications | Industrial plants, district heating, hospitals | Large-scale power generation for grids |

| Operational Scale | Small to medium plants (kW to MW range) | Large-scale plants (MW to hundreds of MW) |

| Heat Utilization | Recovered and used for heating or industrial processes | Waste heat mostly converted back to electricity |

Introduction to CHP and CCPP Systems

CHP (Combined Heat and Power) systems simultaneously generate electricity and useful thermal energy from a single fuel source, increasing overall energy efficiency compared to traditional power generation methods. CCPP (Combined Cycle Power Plant) systems integrate gas and steam turbines to produce electricity with higher efficiency, utilizing waste heat from the gas turbine to power the steam turbine. Understanding the distinctions between CHP and CCPP helps you optimize energy use and reduce operational costs in industrial or commercial settings.

Core Principles of CHP (Combined Heat and Power)

Combined Heat and Power (CHP) systems simultaneously generate electricity and useful thermal energy from a single fuel source, maximizing energy efficiency by capturing heat that would otherwise be wasted. Unlike Combined Cycle Power Plants (CCPP), which primarily focus on electricity generation through gas and steam turbines in series, CHP prioritizes onsite heat recovery to meet heating or cooling demands. Your facility can significantly reduce energy costs and emissions by integrating CHP's core principle of utilizing both power and thermal energy in one optimized process.

Understanding CCPP (Combined Cycle Power Plants)

Combined Cycle Power Plants (CCPP) combine gas and steam turbines to maximize energy efficiency by utilizing waste heat from the gas turbine to power the steam turbine, resulting in higher overall efficiency compared to traditional power plants. CCPP can achieve efficiency levels up to 60%, significantly reducing fuel consumption and greenhouse gas emissions. Understanding this process helps you appreciate how CCPP offers a more sustainable and cost-effective solution for large-scale power generation compared to conventional Combined Heat and Power (CHP) systems.

Key Components in CHP and CCPP

The key components of Combined Heat and Power (CHP) systems include a prime mover such as a gas turbine, reciprocating engine, or fuel cell, a heat recovery system, and a generator for electricity production. Combined Cycle Power Plants (CCPP) primarily consist of a gas turbine, a heat recovery steam generator (HRSG), and a steam turbine, optimizing power generation by using waste heat from the gas turbine to produce additional electricity via steam. CHP focuses on simultaneous production of electricity and thermal energy for onsite use, whereas CCPP emphasizes maximizing electrical output through sequential gas and steam turbine operations.

Efficiency Comparison: CHP vs. CCPP

Combined Heat and Power (CHP) systems achieve overall efficiencies of 60-80% by simultaneously generating electricity and useful thermal energy, significantly surpassing the 40-60% electrical efficiency of Combined Cycle Power Plants (CCPP) that focus primarily on electricity generation. CHP maximizes fuel utilization by capturing waste heat for heating or industrial processes, whereas CCPP uses gas and steam turbines in series to improve electrical output but typically wastes residual heat. Efficiency gains in CHP systems directly reduce fuel consumption and emissions, making them more sustainable compared to the electricity-only optimized CCPP technology.

Environmental Impact: Emissions and Sustainability

CHP (Combined Heat and Power) systems offer higher fuel efficiency by simultaneously producing electricity and useful heat, resulting in lower greenhouse gas emissions compared to traditional power generation. CCPP (Combined Cycle Power Plants) achieve improved efficiency through the integration of gas and steam turbines, reducing CO2 emissions per unit of electricity generated but typically without utilizing waste heat for heating purposes. Your choice between CHP and CCPP should consider the balance between operational efficiency and the potential for sustainable heating solutions that minimize overall environmental impact.

Cost Analysis: Initial Investment and Operational Expenses

CHP (Combined Heat and Power) systems generally require higher initial investment costs due to integrated heat recovery components and specialized equipment, whereas CCPP (Combined Cycle Power Plant) setups involve significant capital for advanced gas and steam turbine technologies. Operational expenses for CHP units tend to be lower because of fuel efficiency gains from simultaneous heat and power production, leading to reduced fuel consumption compared to separate generation methods in CCPP. Maintenance costs in CCPP can be higher owing to the complexity of combined cycle configurations and auxiliary systems, influencing overall lifecycle economics.

Application Areas: Industrial, Commercial, and Residential

Combined Heat and Power (CHP) systems excel in industrial settings by simultaneously generating electricity and useful thermal energy, optimizing energy efficiency in processes like manufacturing and chemical production. In commercial buildings, CHP provides reliable on-site power and heating, reducing operational costs and enhancing energy resilience for offices, hospitals, and schools. Combined Cycle Power Plants (CCPP) primarily serve large-scale utility grids, offering high electrical output with lower emissions but lack the integrated heat utilization suited for residential or smaller-scale commercial applications.

Reliability and Flexibility in Power Generation

Combined Heat and Power (CHP) systems offer high reliability by simultaneously generating electricity and useful thermal energy from a single fuel source, reducing energy losses and enhancing overall efficiency. Combined Cycle Power Plants (CCPP) deliver greater operational flexibility, quickly adjusting power output through gas and steam turbine integration, which supports grid stability during fluctuating demand. CHP excels in consistent, on-site energy supply, while CCPP provides scalable, rapid-response power generation suitable for dynamic grid environments.

Future Trends and Innovations in CHP and CCPP

Future trends in Combined Heat and Power (CHP) emphasize integration with renewable energy sources and advanced digital controls to enhance system efficiency and reduce carbon emissions. Combined Cycle Power Plants (CCPP) are evolving through innovations like hydrogen fuel utilization and improved turbine materials, boosting flexibility and lowering environmental impact. Both technologies benefit from smart grid compatibility and real-time performance analytics, driving smarter energy management and operational optimization.

CHP vs CCPP Infographic

libmatt.com

libmatt.com