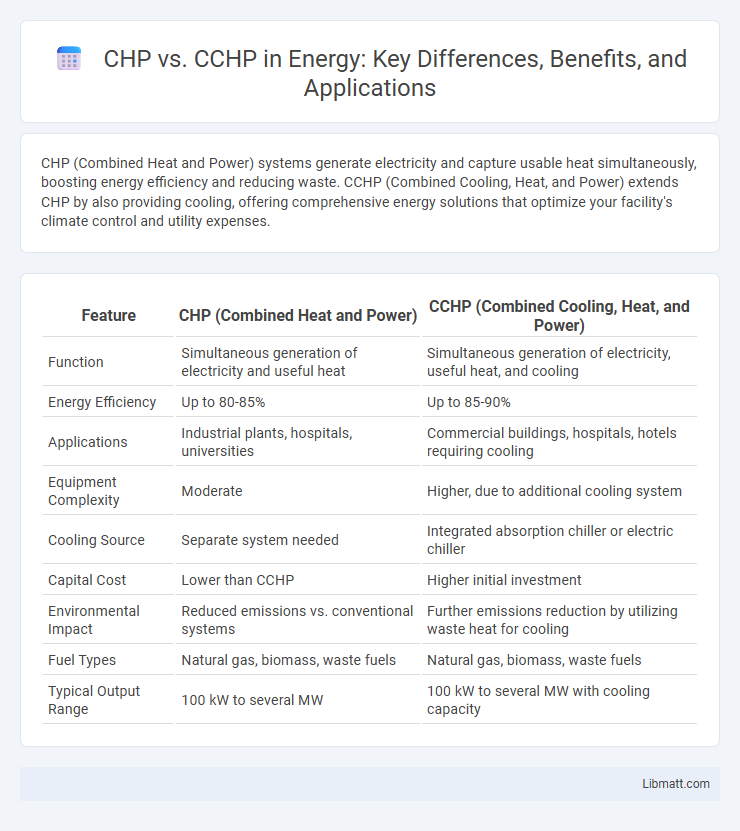

CHP (Combined Heat and Power) systems generate electricity and capture usable heat simultaneously, boosting energy efficiency and reducing waste. CCHP (Combined Cooling, Heat, and Power) extends CHP by also providing cooling, offering comprehensive energy solutions that optimize your facility's climate control and utility expenses.

Table of Comparison

| Feature | CHP (Combined Heat and Power) | CCHP (Combined Cooling, Heat, and Power) |

|---|---|---|

| Function | Simultaneous generation of electricity and useful heat | Simultaneous generation of electricity, useful heat, and cooling |

| Energy Efficiency | Up to 80-85% | Up to 85-90% |

| Applications | Industrial plants, hospitals, universities | Commercial buildings, hospitals, hotels requiring cooling |

| Equipment Complexity | Moderate | Higher, due to additional cooling system |

| Cooling Source | Separate system needed | Integrated absorption chiller or electric chiller |

| Capital Cost | Lower than CCHP | Higher initial investment |

| Environmental Impact | Reduced emissions vs. conventional systems | Further emissions reduction by utilizing waste heat for cooling |

| Fuel Types | Natural gas, biomass, waste fuels | Natural gas, biomass, waste fuels |

| Typical Output Range | 100 kW to several MW | 100 kW to several MW with cooling capacity |

Introduction to CHP and CCHP Technologies

Combined Heat and Power (CHP) systems generate electricity and capture usable heat simultaneously, improving overall energy efficiency by up to 80%. Combined Cooling, Heat, and Power (CCHP) extends CHP technology by integrating absorption chillers to provide cooling alongside electricity and heat, optimizing energy use in buildings and industrial facilities. Your choice between CHP and CCHP depends on the need for cooling services in addition to power and heating demands.

Understanding the Basics: CHP vs CCHP

Combined Heat and Power (CHP) systems simultaneously generate electricity and useful heat from a single fuel source, optimizing energy efficiency by capturing and utilizing heat that would otherwise be wasted. Combined Cooling, Heat, and Power (CCHP) systems extend CHP technology by integrating absorption chillers to convert waste heat into cooling energy, providing a tri-generation solution that enhances energy utilization and reduces overall emissions. Understanding the operational differences between CHP and CCHP is crucial for selecting the appropriate technology based on specific energy demands and sustainability goals.

Key Components of CHP and CCHP Systems

CHP (Combined Heat and Power) systems consist primarily of a prime mover such as a gas turbine or engine, a generator for electricity production, and a heat recovery unit that captures waste thermal energy. CCHP (Combined Cooling, Heat, and Power) systems integrate all CHP components with an absorption chiller or cooling equipment that converts recovered heat into chilled water for air conditioning. The inclusion of cooling technology in CCHP enhances energy efficiency by utilizing the thermal energy for multiple applications beyond electricity and heat.

How CHP and CCHP Work: Process Overview

Combined Heat and Power (CHP) systems generate electricity on-site by simultaneously producing usable heat from the same energy source, enhancing overall efficiency. Combined Cooling, Heat, and Power (CCHP) extends this concept by integrating absorption chillers that convert waste heat into cooling energy, enabling your facility to meet electricity, heating, and cooling needs from a single system. Both systems optimize fuel use and reduce emissions by capturing and utilizing heat that would otherwise be wasted in conventional power generation.

Energy Efficiency Comparison: CHP vs CCHP

Combined Heat and Power (CHP) systems convert fuel into both electricity and useful heat, achieving efficiency rates of 60-80%. Combined Cooling, Heat, and Power (CCHP) systems, also known as trigeneration, extend this efficiency by utilizing waste heat for cooling through absorption chillers, reaching overall energy efficiencies of up to 85-90%. Choosing CCHP can maximize your facility's energy utilization by integrating electricity, heating, and cooling demands into a single optimized system.

Environmental Impacts and Emissions

CHP (Combined Heat and Power) systems significantly reduce greenhouse gas emissions by utilizing fuel more efficiently compared to conventional power generation. CCHP (Combined Cooling, Heat, and Power) extends these environmental benefits by integrating cooling capabilities, further minimizing energy waste and lowering overall carbon footprint. Your choice of CCHP can lead to enhanced sustainability through reduced fossil fuel consumption and decreased emissions of pollutants such as CO2 and NOx.

Costs and Economic Benefits

CHP (Combined Heat and Power) systems typically have lower initial capital costs compared to CCHP (Combined Cooling, Heating, and Power) systems due to simpler technology and fewer components. CCHP offers enhanced economic benefits by maximizing energy utilization, reducing fuel consumption, and lowering operational costs through integrated cooling, heating, and power generation. Over time, the increased efficiency and energy savings of CCHP can result in a faster return on investment despite higher upfront expenses.

Suitable Applications for CHP and CCHP

CHP systems are ideal for facilities with consistent heat and power demands such as industrial plants, hospitals, and universities, where simultaneous generation can maximize energy efficiency. CCHP systems are better suited for buildings requiring electricity, heating, and cooling, including large commercial complexes or district energy systems, by integrating absorption chillers for cooling needs. Choosing between CHP and CCHP depends on whether Your application necessitates combined cooling capabilities alongside heat and power.

Challenges and Limitations

CHP systems face challenges such as fuel supply variability, high upfront capital costs, and limited flexibility in adapting to fluctuating energy demands. CCHP systems, while more efficient by simultaneously producing cooling, heating, and power, encounter complexities in system integration, higher maintenance requirements, and space constraints for equipment installation. Both systems must address regulatory hurdles and potential emissions limitations that impact widespread adoption.

Future Trends in Distributed Energy: CHP and CCHP

Future trends in distributed energy emphasize the growing integration of Combined Heat and Power (CHP) and Combined Cooling, Heat, and Power (CCHP) systems to enhance energy efficiency and reduce carbon emissions. Advanced CHP solutions leverage waste heat recovery to generate electricity and thermal energy on-site, while CCHP expands this capability by incorporating cooling production, enabling versatile applications in commercial and industrial sectors. Innovations in smart grid technology, digital monitoring, and renewable fuel integration are driving increased adoption of CHP and CCHP, fostering resilient, decentralized energy networks.

CHP vs CCHP Infographic

libmatt.com

libmatt.com