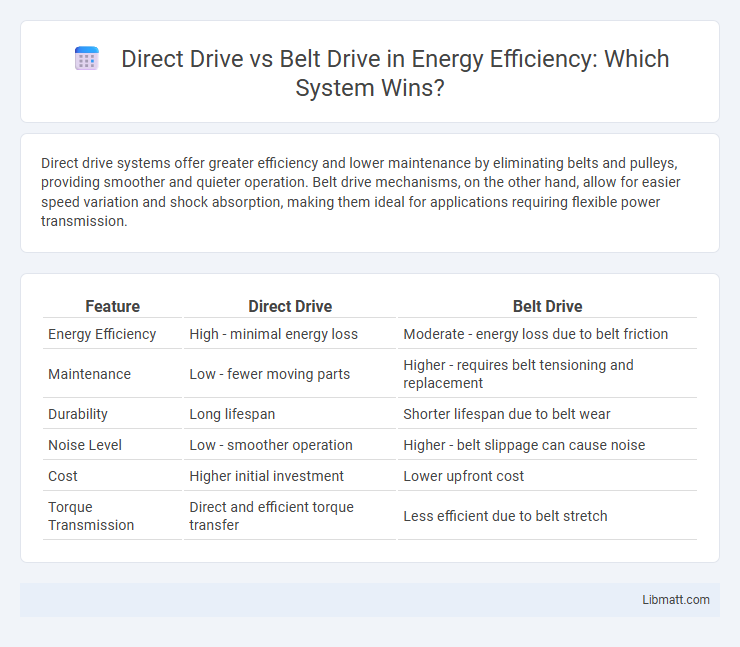

Direct drive systems offer greater efficiency and lower maintenance by eliminating belts and pulleys, providing smoother and quieter operation. Belt drive mechanisms, on the other hand, allow for easier speed variation and shock absorption, making them ideal for applications requiring flexible power transmission.

Table of Comparison

| Feature | Direct Drive | Belt Drive |

|---|---|---|

| Energy Efficiency | High - minimal energy loss | Moderate - energy loss due to belt friction |

| Maintenance | Low - fewer moving parts | Higher - requires belt tensioning and replacement |

| Durability | Long lifespan | Shorter lifespan due to belt wear |

| Noise Level | Low - smoother operation | Higher - belt slippage can cause noise |

| Cost | Higher initial investment | Lower upfront cost |

| Torque Transmission | Direct and efficient torque transfer | Less efficient due to belt stretch |

Introduction to Drive Mechanisms

Direct drive systems transmit power directly from the motor to the load, eliminating intermediary components and reducing mechanical losses. Belt drive mechanisms use belts and pulleys to transfer rotational motion, offering flexibility in distance and speed variation. Understanding the operational principles, efficiency, and application contexts of each drive mechanism is essential for selecting the optimal solution in mechanical and industrial systems.

What is a Direct Drive System?

A Direct Drive System connects the motor directly to the drive mechanism, eliminating the need for belts or gears, which reduces mechanical losses and increases efficiency. This system offers precise torque control and higher reliability due to fewer moving parts and less wear and tear. It is commonly used in applications requiring high precision and low maintenance, such as turntables, industrial machinery, and electric vehicles.

What is a Belt Drive System?

A belt drive system uses a flexible belt made of rubber, leather, or synthetic materials to transfer power between pulleys, offering smooth and quiet operation with reduced vibration. It is commonly found in machinery, bicycles, and automotive engines, providing flexibility in the distance between shafts and absorbing shock loads. Understanding what a belt drive system entails helps you choose the right transmission method based on maintenance needs and performance requirements.

Key Differences: Direct Drive vs Belt Drive

Direct drive systems connect the motor directly to the wheel or component, resulting in higher efficiency, reduced maintenance, and quieter operation compared to belt drive systems. Belt drive uses a flexible belt to transfer power between the motor and the wheel, offering smoother acceleration and easier replacement but generally lower efficiency and more noise. Key differences include power transmission method, maintenance requirements, noise levels, and overall durability.

Performance Comparison

Direct drive systems offer superior performance with higher efficiency, reduced power loss, and more precise control compared to belt drive systems, which can suffer from slippage and wear over time. You benefit from direct drive's smoother operation and lower maintenance requirements, making it ideal for applications demanding consistent torque and speed. Belt drives, while cheaper and quieter, typically lag in responsiveness and power transfer accuracy, impacting overall performance in high-precision environments.

Noise and Vibration Levels

Direct drive turntables produce lower noise and vibration levels due to the absence of belts, resulting in a cleaner audio output ideal for precision listening. Belt drive systems can introduce additional noise and vibration because the belt may wear out or slip, affecting sound quality. Your choice depends on whether you prioritize quiet operation and minimal resonance, which direct drive typically provides.

Maintenance Requirements

Direct drive systems offer lower maintenance requirements since they have fewer moving parts and no belts that can wear out or slip. Belt drive systems require periodic inspection, belt tension adjustment, and eventual replacement due to belt wear and potential slippage. You can reduce downtime and maintenance costs significantly by choosing direct drive technology for applications demanding reliability.

Cost and Longevity

Direct drive systems generally have a higher upfront cost but offer greater longevity due to fewer moving parts and reduced maintenance requirements. Belt drive systems are more affordable initially but may require frequent belt replacements and adjustments, leading to higher long-term expenses. Your choice between direct drive and belt drive should consider both your budget constraints and the desired durability of the equipment.

Best Use Cases for Each System

Direct drive systems excel in applications requiring high precision, such as turntables for audiophiles and industrial machinery needing minimal vibration and maximum torque transfer. Belt drive systems are ideal for scenarios where noise reduction and shock absorption are important, like in home audio turntables and fitness equipment, providing smoother operation and less wear on components. Your choice depends on whether you prioritize accuracy and durability or quieter, more forgiving performance.

Conclusion: Which Drive System is Better?

Direct drive systems offer superior torque, reduced maintenance, and higher efficiency compared to belt drive systems, making them ideal for precision applications and heavy-duty use. Belt drive systems tend to be quieter and less expensive initially but require regular maintenance and have lower overall durability. For long-term performance and minimal upkeep, direct drive is generally the better choice.

Direct drive vs Belt drive Infographic

libmatt.com

libmatt.com