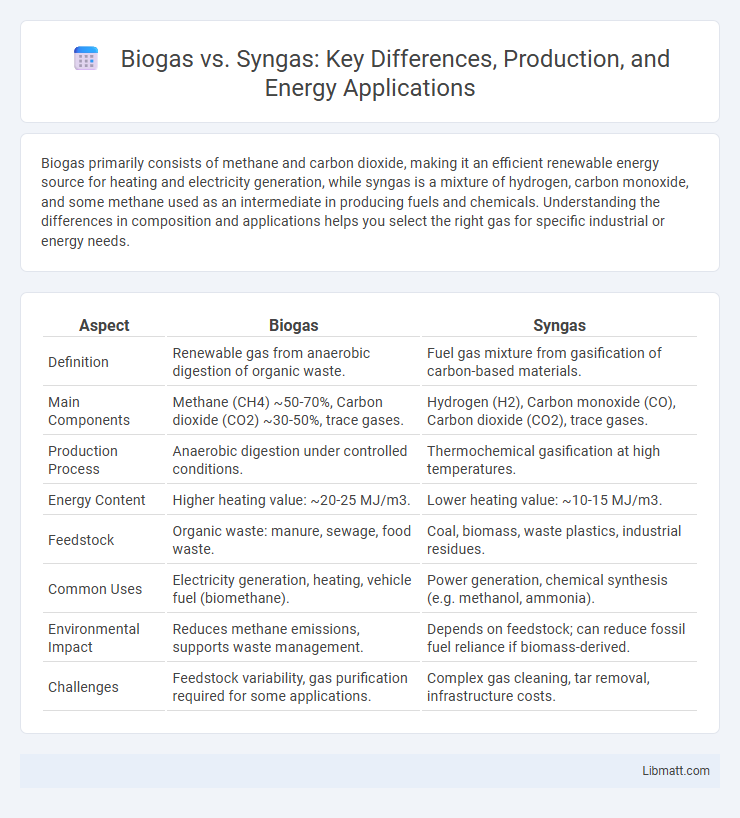

Biogas primarily consists of methane and carbon dioxide, making it an efficient renewable energy source for heating and electricity generation, while syngas is a mixture of hydrogen, carbon monoxide, and some methane used as an intermediate in producing fuels and chemicals. Understanding the differences in composition and applications helps you select the right gas for specific industrial or energy needs.

Table of Comparison

| Aspect | Biogas | Syngas |

|---|---|---|

| Definition | Renewable gas from anaerobic digestion of organic waste. | Fuel gas mixture from gasification of carbon-based materials. |

| Main Components | Methane (CH4) ~50-70%, Carbon dioxide (CO2) ~30-50%, trace gases. | Hydrogen (H2), Carbon monoxide (CO), Carbon dioxide (CO2), trace gases. |

| Production Process | Anaerobic digestion under controlled conditions. | Thermochemical gasification at high temperatures. |

| Energy Content | Higher heating value: ~20-25 MJ/m3. | Lower heating value: ~10-15 MJ/m3. |

| Feedstock | Organic waste: manure, sewage, food waste. | Coal, biomass, waste plastics, industrial residues. |

| Common Uses | Electricity generation, heating, vehicle fuel (biomethane). | Power generation, chemical synthesis (e.g. methanol, ammonia). |

| Environmental Impact | Reduces methane emissions, supports waste management. | Depends on feedstock; can reduce fossil fuel reliance if biomass-derived. |

| Challenges | Feedstock variability, gas purification required for some applications. | Complex gas cleaning, tar removal, infrastructure costs. |

Introduction to Biogas and Syngas

Biogas is a renewable energy source produced through the anaerobic digestion of organic waste, primarily consisting of methane (CH4) and carbon dioxide (CO2), used for heating, electricity, and vehicle fuel. Syngas, or synthesis gas, is a fuel gas mixture mainly composed of hydrogen (H2), carbon monoxide (CO), and some carbon dioxide (CO2), generated from the gasification of carbon-rich materials like coal, biomass, or municipal waste for power generation and chemical synthesis. Both gases serve as alternative fuels but differ significantly in production processes, composition, and applications.

Composition and Chemical Properties

Biogas primarily consists of methane (CH4) around 50-70% and carbon dioxide (CO2) about 30-50%, with trace amounts of hydrogen sulfide (H2S) and moisture, making it a combustible gas with a high energy content. Syngas is a mixture of hydrogen (H2), carbon monoxide (CO), and carbon dioxide (CO2), typically containing 20-30% H2, 20-30% CO, and 30-50% CO2, characterized by its high reactivity and suitability for chemical synthesis. Understanding the chemical properties and composition of these gases helps optimize your applications in energy production or industrial processes.

Feedstock Sources and Availability

Biogas primarily originates from the anaerobic digestion of organic waste materials such as agricultural residues, animal manure, and municipal solid waste, making its feedstock widely available in rural and urban settings with organic waste streams. Syngas feedstock consists mainly of carbon-rich materials like coal, biomass, and industrial waste gases, providing flexibility in sourcing but often requiring more complex gasification technology. The availability of feedstock for biogas is generally more sustainable and renewable, while syngas benefits from diverse carbonaceous inputs, including fossil-based and renewable resources.

Production Processes and Technologies

Biogas is produced through anaerobic digestion of organic waste, utilizing bacteria to break down materials like agricultural residues and manure in oxygen-free environments, primarily involving digesters. Syngas is generated via gasification, a high-temperature process that converts carbon-rich feedstocks such as coal, biomass, or waste into a mixture of hydrogen, carbon monoxide, and carbon dioxide through partial oxidation. Understanding these distinct production processes helps optimize your energy strategy by selecting suitable technologies based on feedstock availability and desired output.

Energy Yield and Efficiency Comparison

Biogas typically yields 20-25 MJ/m3 with an energy efficiency of around 60-70% when used in combined heat and power (CHP) systems. Syngas, derived from gasification processes, offers a higher energy content of approximately 10-15 MJ/m3 but can reach efficiency rates up to 80% when converted through advanced gas engines or turbines. The difference in energy density and conversion efficiency makes syngas more suitable for high-temperature industrial applications, while biogas is preferred for decentralized power generation and heat recovery.

Environmental Impact and Sustainability

Biogas, produced through the anaerobic digestion of organic waste, offers significant environmental benefits by reducing methane emissions from landfills and promoting renewable energy use with a lower carbon footprint compared to fossil fuels. Syngas, derived from gasification of biomass or fossil fuels, has a more complex environmental impact due to potential emissions of pollutants like tar and particulate matter, though it can contribute to sustainability when produced from sustainable biomass sources. Both gases support circular economy principles, but biogas typically presents a more immediate and cleaner solution for waste management and renewable energy integration.

Applications in Industry and Power Generation

Biogas, rich in methane, is extensively used for heating, electricity generation, and as a renewable fuel in combined heat and power (CHP) plants, primarily in agricultural, municipal, and waste management industries. Syngas, composed mainly of hydrogen, carbon monoxide, and carbon dioxide, serves as a crucial intermediate in chemical manufacturing, Fischer-Tropsch synthesis, and as a fuel for gas turbines in power plants due to its higher calorific value and versatility. Both gases enhance industrial sustainability by substituting fossil fuels and enabling efficient energy conversion in sectors like steel production, refining, and large-scale power generation.

Economic Considerations and Cost Analysis

Biogas production typically benefits from lower feedstock costs due to the use of organic waste materials, making it economically viable for small to medium-scale applications. Syngas, derived primarily from gasification of coal, biomass, or natural gas, involves higher capital expenditure and operational costs but offers greater versatility in downstream applications like chemical synthesis and fuel production. Cost analysis shows biogas systems have shorter payback periods, while syngas projects demand significant investment but provide long-term economic benefits through integration with industrial processes.

Challenges and Limitations

Biogas faces challenges such as the presence of impurities like hydrogen sulfide and moisture, which require upgrading for efficient use, and its energy content is lower compared to conventional fuels. Syngas production involves complex gasification processes that demand high operational temperatures and feedstock variability, leading to potential tar formation and equipment corrosion. You must consider these limitations when choosing between biogas and syngas for energy applications to ensure system efficiency and reliability.

Future Prospects and Innovations

Biogas and syngas show promising future prospects with innovations in renewable energy integration and carbon capture technologies enhancing their sustainability. Emerging advancements in biogas upgrading and syngas catalytic conversion improve energy efficiency and reduce greenhouse gas emissions. The development of hybrid systems combining biogas and syngas production can optimize resource utilization and support decarbonization goals.

Biogas vs Syngas Infographic

libmatt.com

libmatt.com