Flue gas desulfurization (FGD) removes sulfur dioxide (SO2) from exhaust gases, reducing acid rain and air pollution, while selective catalytic reduction (SCR) targets nitrogen oxides (NOx) emissions by converting them into harmless nitrogen and water vapor. Choosing the appropriate technology depends on your specific emission control needs, with FGD focusing on SO2 reduction and SCR addressing NOx compliance.

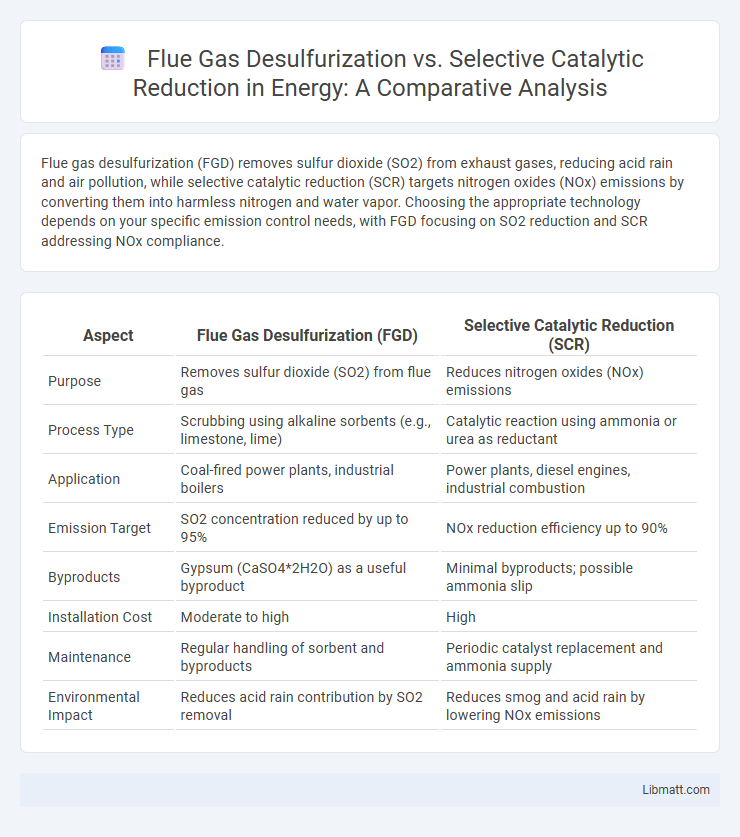

Table of Comparison

| Aspect | Flue Gas Desulfurization (FGD) | Selective Catalytic Reduction (SCR) |

|---|---|---|

| Purpose | Removes sulfur dioxide (SO2) from flue gas | Reduces nitrogen oxides (NOx) emissions |

| Process Type | Scrubbing using alkaline sorbents (e.g., limestone, lime) | Catalytic reaction using ammonia or urea as reductant |

| Application | Coal-fired power plants, industrial boilers | Power plants, diesel engines, industrial combustion |

| Emission Target | SO2 concentration reduced by up to 95% | NOx reduction efficiency up to 90% |

| Byproducts | Gypsum (CaSO4*2H2O) as a useful byproduct | Minimal byproducts; possible ammonia slip |

| Installation Cost | Moderate to high | High |

| Maintenance | Regular handling of sorbent and byproducts | Periodic catalyst replacement and ammonia supply |

| Environmental Impact | Reduces acid rain contribution by SO2 removal | Reduces smog and acid rain by lowering NOx emissions |

Overview of Flue Gas Desulfurization (FGD)

Flue Gas Desulfurization (FGD) is a pollution control technology used to remove sulfur dioxide (SO2) from exhaust flue gases of fossil-fuel power plants. Common FGD systems include wet scrubbers, dry scrubbers, and spray dry scrubbers, which use sorbents like limestone or lime to chemically absorb SO2. FGD significantly reduces acid rain precursors and meets regulatory emissions standards, making it essential for environmental compliance in coal and oil-fired power generation.

Introduction to Selective Catalytic Reduction (SCR)

Selective Catalytic Reduction (SCR) is an advanced emission control technology designed to reduce nitrogen oxides (NOx) emissions from industrial exhaust streams by converting them into nitrogen and water using a catalyst and a reductant like ammonia or urea. SCR systems operate efficiently at high temperatures, making them suitable for power plants and large combustion sources. Unlike Flue Gas Desulfurization (FGD), which targets sulfur dioxide (SO2) removal, SCR specifically focuses on NOx abatement to meet stringent environmental regulations.

Key Differences Between FGD and SCR

Flue gas desulfurization (FGD) primarily targets the removal of sulfur dioxide (SO2) from exhaust gases using wet or dry scrubbers, typically involving chemical reactions with lime or limestone. Selective catalytic reduction (SCR) focuses on reducing nitrogen oxides (NOx) emissions by injecting ammonia or urea in the presence of a catalyst, converting NOx into nitrogen and water. FGD systems are essential for controlling acid rain precursors, whereas SCR units are critical for meeting stringent NOx emission standards in power plants and industrial facilities.

Pollutants Targeted by Each Technology

Flue gas desulfurization (FGD) primarily targets sulfur dioxide (SO2) emissions generated from burning fossil fuels, significantly reducing acid rain-causing pollutants. Selective catalytic reduction (SCR) focuses on nitrogen oxides (NOx) by converting them into nitrogen and water through a catalytic reaction, thereby reducing smog and ozone formation. Both technologies effectively reduce specific harmful pollutants but address different components of flue gas emissions.

Process Mechanisms: FGD vs SCR

Flue gas desulfurization (FGD) removes sulfur dioxide (SO2) from exhaust gases by utilizing a chemical scrubbing process, often involving a slurry of limestone or lime that reacts with SO2 to form gypsum. Selective catalytic reduction (SCR) reduces nitrogen oxides (NOx) emissions through catalytic reactions where ammonia or urea is injected into the flue gas, converting NOx into harmless nitrogen and water. Both processes enhance air quality by targeting different pollutants with distinct chemical mechanisms optimized for industrial emissions control.

Efficiency Comparison: FGD and SCR Systems

Flue gas desulfurization (FGD) systems achieve sulfur dioxide (SO2) removal efficiencies typically exceeding 90%, often reaching up to 95-99%, making them highly effective for controlling acid rain precursors. Selective catalytic reduction (SCR) systems target nitrogen oxides (NOx) with removal efficiencies ranging from 70% to 95%, depending on catalyst quality, temperature, and operational parameters. Comparing both, FGD excels in SO2 removal efficiency, while SCR is specialized for NOx reduction, making them complementary technologies in comprehensive flue gas treatment.

Implementation Costs and Operational Expenses

Flue gas desulfurization (FGD) systems typically have higher initial implementation costs, ranging from $100 to $300 per installed kilowatt, due to the need for large scrubbers and extensive waste handling infrastructure. Operational expenses for FGD include significant reagent consumption, primarily limestone or lime, and byproduct management, which can amount to 2-4% of total plant operating costs. Selective catalytic reduction (SCR) systems generally incur lower installation costs, approximately $50 to $150 per installed kilowatt, but experience continuous expenses related to catalyst replacement and ammonia or urea consumption, leading to operational costs around 1-3% of plant expenditures.

Environmental Impacts and Byproducts

Flue gas desulfurization (FGD) effectively reduces sulfur dioxide emissions, producing gypsum as a useful byproduct that minimizes environmental harm. Selective catalytic reduction (SCR) targets nitrogen oxides, converting them into harmless nitrogen and water vapor, though it may generate ammonia slip if not properly managed. Your choice between these technologies depends on the specific emissions profile and environmental regulations applicable to your facility.

Industrial Applications and Use Cases

Flue gas desulfurization (FGD) is primarily used in coal-fired power plants and industrial boilers to remove sulfur dioxide (SO2) emissions, protecting the environment from acid rain and meeting regulatory standards. Selective catalytic reduction (SCR) targets nitrogen oxides (NOx) in industries such as power generation, cement manufacturing, and diesel engine exhaust systems, enhancing air quality by converting NOx into harmless nitrogen and water. Understanding your facility's emission profile helps determine whether FGD, SCR, or a combination of both technologies is essential for compliance and operational efficiency.

Future Trends in Emissions Control Technologies

Flue gas desulfurization (FGD) and selective catalytic reduction (SCR) remain vital technologies for controlling sulfur dioxide (SO2) and nitrogen oxides (NOx) emissions, respectively, in power plant operations. Future trends indicate integration of advanced catalysts in SCR systems to enhance NOx reduction efficiency at lower temperatures, while FGD technologies are evolving toward hybrid systems combining wet and dry scrubbing methods for improved SO2 capture and reduced water consumption. Digital monitoring and AI-driven process optimization are increasingly applied to both FGD and SCR systems, enabling real-time emissions control and predictive maintenance for regulatory compliance and operational cost reduction.

Flue gas desulfurization vs Selective catalytic reduction Infographic

libmatt.com

libmatt.com