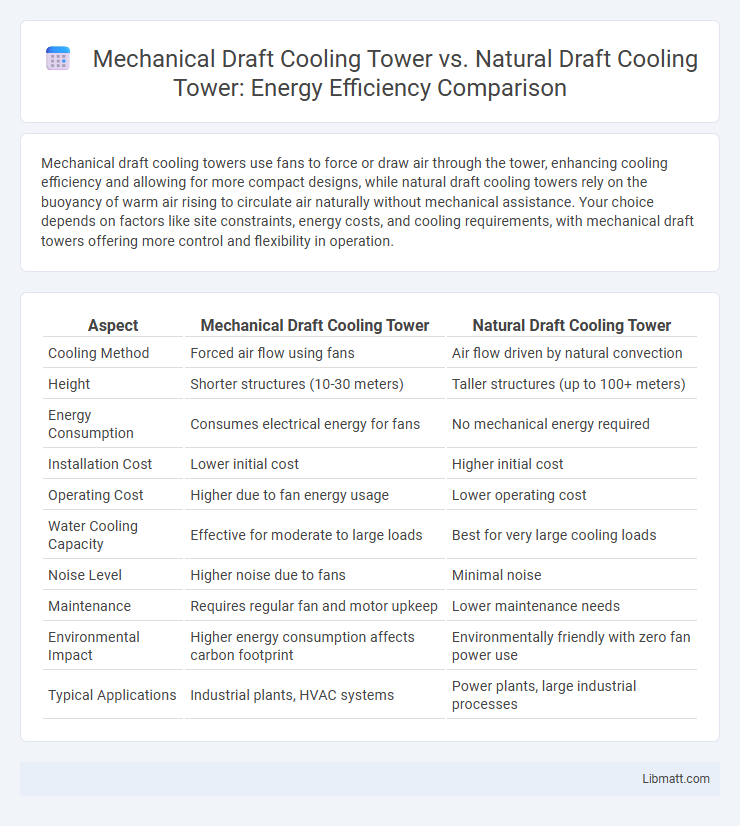

Mechanical draft cooling towers use fans to force or draw air through the tower, enhancing cooling efficiency and allowing for more compact designs, while natural draft cooling towers rely on the buoyancy of warm air rising to circulate air naturally without mechanical assistance. Your choice depends on factors like site constraints, energy costs, and cooling requirements, with mechanical draft towers offering more control and flexibility in operation.

Table of Comparison

| Aspect | Mechanical Draft Cooling Tower | Natural Draft Cooling Tower |

|---|---|---|

| Cooling Method | Forced air flow using fans | Air flow driven by natural convection |

| Height | Shorter structures (10-30 meters) | Taller structures (up to 100+ meters) |

| Energy Consumption | Consumes electrical energy for fans | No mechanical energy required |

| Installation Cost | Lower initial cost | Higher initial cost |

| Operating Cost | Higher due to fan energy usage | Lower operating cost |

| Water Cooling Capacity | Effective for moderate to large loads | Best for very large cooling loads |

| Noise Level | Higher noise due to fans | Minimal noise |

| Maintenance | Requires regular fan and motor upkeep | Lower maintenance needs |

| Environmental Impact | Higher energy consumption affects carbon footprint | Environmentally friendly with zero fan power use |

| Typical Applications | Industrial plants, HVAC systems | Power plants, large industrial processes |

Introduction to Cooling Towers

Cooling towers are essential systems used to dissipate heat from industrial processes, power plants, and HVAC applications. Mechanical draft cooling towers use fans to force or draw air through the tower, enhancing heat transfer efficiency, whereas natural draft cooling towers rely on buoyancy and temperature differences to circulate air naturally without mechanical assistance. Understanding the operational principles of these cooling towers helps you select the right system based on site conditions, energy consumption, and cooling capacity needs.

Overview of Mechanical Draft Cooling Towers

Mechanical draft cooling towers use fans powered by electricity or motors to force or draw air through the tower, enhancing heat dissipation efficiency. These towers are characterized by their controlled airflow, which allows precise regulation of temperature and humidity levels inside the structure. Common applications include power plants, industrial processes, and HVAC systems, where compact design and high cooling capacity are essential.

Overview of Natural Draft Cooling Towers

Natural draft cooling towers rely on the buoyancy of warm air rising naturally through a large, hyperbolic structure to cool water without mechanical assistance, making them energy-efficient and ideal for large industrial applications. These towers are typically constructed from concrete or steel and can reach heights exceeding 100 meters to maximize airflow and enhance thermal performance. Your choice of a natural draft cooling tower can significantly reduce operational costs and environmental impact compared to mechanical draft towers, especially in projects requiring large-scale heat dissipation.

Key Design Differences

Mechanical draft cooling towers use fans or mechanical devices to enhance air flow through the tower, allowing precise control of cooling efficiency and placement flexibility. Natural draft cooling towers rely on the buoyant force generated by the temperature difference between the rising warm air inside the tower and the cooler external air, requiring tall hyperbolic structures for effective airflow. The key design differences include the presence of mechanical fans in mechanical draft towers and the use of height and natural convection in natural draft towers, impacting size, cost, and site requirements.

Operational Principles

Mechanical draft cooling towers use fans to force or draw air through the tower, enhancing heat transfer by increasing airflow velocity and improving cooling efficiency. In contrast, natural draft cooling towers rely on the buoyancy of warm air rising through the tower's chimney effect, resulting in a slower, passive airflow without energy consumption from fans. Your choice between these systems depends on operational requirements such as space, energy costs, and cooling capacity.

Efficiency Comparison

Mechanical draft cooling towers achieve higher efficiency by using fans to control airflow, enabling quicker heat dissipation and better temperature regulation. Natural draft cooling towers rely on buoyancy-driven air movement, resulting in lower efficiency due to less controllable airflow and greater susceptibility to environmental conditions. Your choice should consider the required cooling load and operational cost, as mechanical draft systems offer more precise control and consistent performance.

Energy Consumption and Costs

Mechanical draft cooling towers use fans powered by electricity, leading to higher energy consumption and increased operational costs compared to natural draft cooling towers, which rely on natural airflow. Your choice impacts long-term expenses; mechanical draft towers offer better control and efficiency in smaller spaces but incur ongoing energy costs. Natural draft towers have lower energy costs due to passive cooling but require larger footprints and higher initial construction expenses.

Maintenance Requirements

Mechanical draft cooling towers require more frequent maintenance due to their reliance on fans, motors, and mechanical components that are prone to wear and require lubrication, inspection, and occasional replacement. Natural draft cooling towers have lower maintenance demands because they operate without mechanical parts, relying on natural airflow, but still need regular cleaning to prevent scaling and biological growth. Proper maintenance in both types ensures optimal heat exchange efficiency and prolongs equipment lifespan.

Environmental Impact

Mechanical draft cooling towers consume significant energy due to their reliance on fans, contributing to higher carbon emissions compared to natural draft cooling towers. Natural draft cooling towers utilize buoyancy-driven airflow, reducing power consumption and minimizing environmental impact by lowering greenhouse gas emissions. Your choice between these two affects energy efficiency and ecological footprint, making natural draft towers preferable for sustainable operations.

Application Suitability and Selection Criteria

Mechanical draft cooling towers are ideal for applications requiring precise temperature control and compact footprints, often used in industrial processes and HVAC systems where forced airflow enhances heat dissipation. Natural draft cooling towers suit large-scale power plants and industrial facilities where ambient wind currents provide sufficient ventilation, favoring energy efficiency and lower operational costs over mechanical reliability. Your selection should consider site space, climate, energy use, and maintenance capacity to determine the most efficient tower type for your cooling needs.

Mechanical draft cooling tower vs Natural draft cooling tower Infographic

libmatt.com

libmatt.com