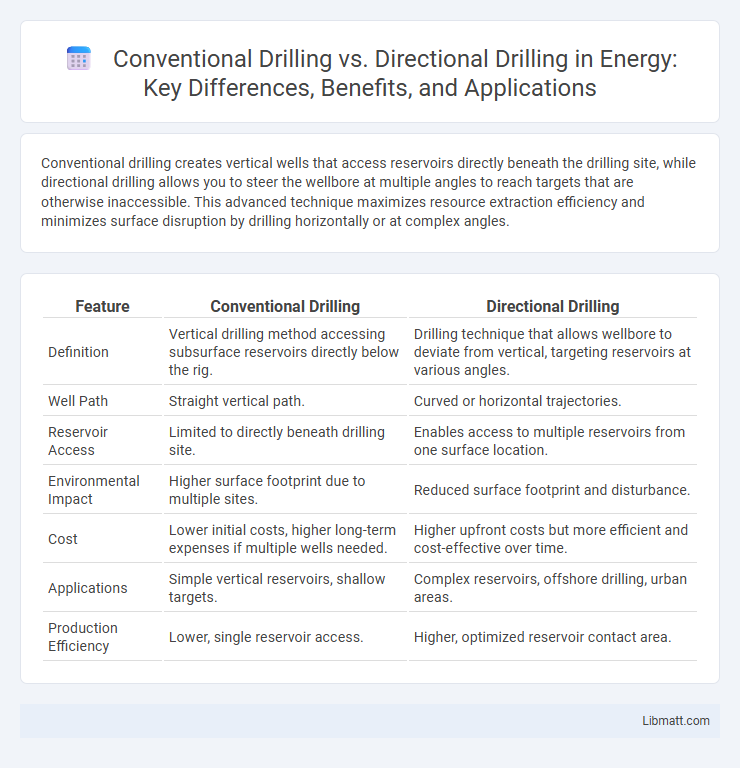

Conventional drilling creates vertical wells that access reservoirs directly beneath the drilling site, while directional drilling allows you to steer the wellbore at multiple angles to reach targets that are otherwise inaccessible. This advanced technique maximizes resource extraction efficiency and minimizes surface disruption by drilling horizontally or at complex angles.

Table of Comparison

| Feature | Conventional Drilling | Directional Drilling |

|---|---|---|

| Definition | Vertical drilling method accessing subsurface reservoirs directly below the rig. | Drilling technique that allows wellbore to deviate from vertical, targeting reservoirs at various angles. |

| Well Path | Straight vertical path. | Curved or horizontal trajectories. |

| Reservoir Access | Limited to directly beneath drilling site. | Enables access to multiple reservoirs from one surface location. |

| Environmental Impact | Higher surface footprint due to multiple sites. | Reduced surface footprint and disturbance. |

| Cost | Lower initial costs, higher long-term expenses if multiple wells needed. | Higher upfront costs but more efficient and cost-effective over time. |

| Applications | Simple vertical reservoirs, shallow targets. | Complex reservoirs, offshore drilling, urban areas. |

| Production Efficiency | Lower, single reservoir access. | Higher, optimized reservoir contact area. |

Introduction to Drilling Methods

Conventional drilling involves a vertical or nearly vertical wellbore, typically used for straightforward subsurface access and simpler geological formations. Directional drilling allows precision steering of the well path, enabling access to multiple reservoirs from a single surface location and targeting complex geological structures. Both methods are critical in oil and gas exploration, with directional drilling enhancing reservoir contact and production efficiency.

What is Conventional Drilling?

Conventional drilling is a vertical drilling method used to access underground resources by creating a straight borehole perpendicular to the surface. This technique is primarily employed for extracting oil, natural gas, and minerals directly beneath the drilling site. Conventional drilling is favored for its simplicity, lower cost, and ease of implementation compared to more complex drilling techniques.

What is Directional Drilling?

Directional drilling is a technique used to steer a wellbore along a predetermined path, allowing access to reservoirs that are not directly beneath the drilling site. Unlike conventional drilling, which follows a vertical trajectory, directional drilling enables horizontal or angled penetration, enhancing resource extraction efficiency. This method optimizes well placement, reduces environmental impact, and maximizes reservoir contact, benefiting your operational outcomes.

Key Differences Between Conventional and Directional Drilling

Conventional drilling involves drilling a vertical wellbore straight down to access oil or gas reserves, while directional drilling allows for intentional deviation to reach multiple targets or navigate around obstacles. Directional drilling offers enhanced control over well trajectory, enabling horizontal and multilateral wells that increase reservoir exposure and recovery rates. Conventional drilling is generally simpler and less expensive, but directional drilling provides greater flexibility and efficiency in complex geological formations.

Advantages of Conventional Drilling

Conventional drilling offers a straightforward and cost-effective approach for vertical wellbores, making it ideal for accessing resources directly beneath the drilling site. Its simplicity reduces the risk of mechanical failures and minimizes operational complexities, ensuring faster drilling times and lower overall expenses. You benefit from reliable well integrity and easier well control compared to more complex directional drilling techniques.

Advantages of Directional Drilling

Directional drilling offers precise control over the wellbore path, enabling access to multiple reservoirs from a single surface location and reducing environmental impact. It allows for increased production efficiency by reaching offshore or hard-to-access targets that conventional vertical drilling cannot. Your ability to steer the drill bit also minimizes surface disturbance and optimizes resource extraction in complex geological formations.

Limitations of Each Drilling Technique

Conventional drilling is limited by its vertical trajectory, restricting access to reservoirs located beneath obstacles or at extended lateral distances, which can lead to inefficient resource extraction. Directional drilling overcomes these spatial constraints by allowing precise wellbore navigation, but it faces higher operational costs and increased technical complexity, including challenges in maintaining wellbore stability and managing torque and drag. Your choice between these techniques should consider reservoir location, project budget, and the technical feasibility of well path design.

Technological Innovations in Drilling

Technological innovations in conventional drilling include advancements in rotary bits and automated drilling rigs that enhance speed and efficiency for vertical wells. Directional drilling technology incorporates sophisticated downhole motors, measurement-while-drilling (MWD) systems, and rotary steerable systems (RSS) to precisely control well trajectories and access complex reservoirs. These innovations significantly reduce drilling time and costs while maximizing reservoir contact and hydrocarbon recovery.

Applications and Industry Use Cases

Conventional drilling is primarily used for vertical wells in oil and gas extraction, water wells, and geothermal energy projects where the target is directly beneath the drilling site. Directional drilling enables precise well placement in complex reservoirs, offshore platforms, and urban areas, optimizing resource recovery and minimizing environmental impact. Your choice between these methods depends on the geological conditions and the specific needs of the oil and gas, mining, or construction industries.

Future Trends in Drilling Technologies

Future trends in drilling technologies emphasize automation, real-time data analytics, and enhanced precision, significantly advancing both conventional drilling and directional drilling methods. Directional drilling is set to benefit from improved downhole sensors and machine learning algorithms, enabling more accurate well placement and reduced environmental impact. You can expect these innovations to optimize resource extraction while minimizing operational costs and risks.

Conventional drilling vs Directional drilling Infographic

libmatt.com

libmatt.com