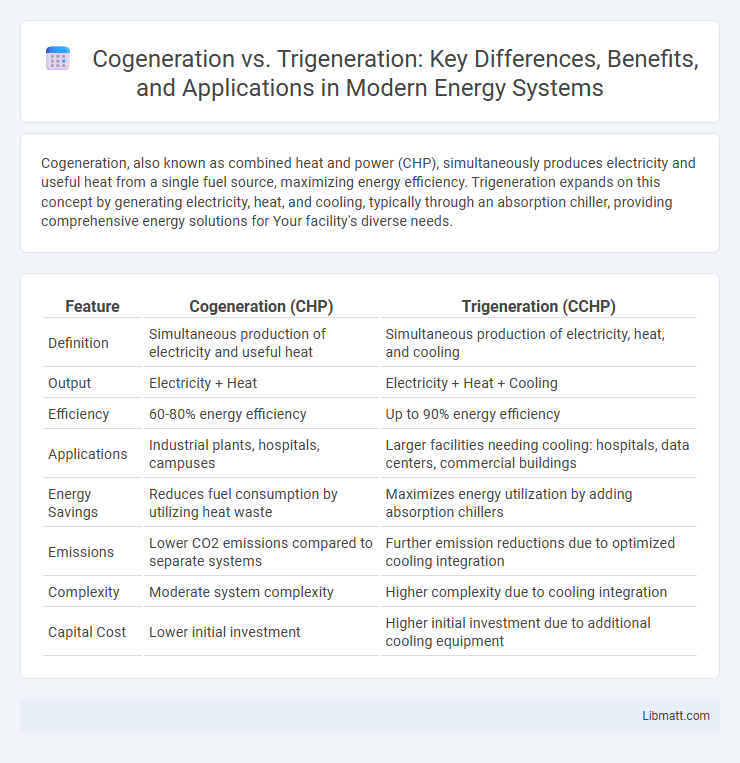

Cogeneration, also known as combined heat and power (CHP), simultaneously produces electricity and useful heat from a single fuel source, maximizing energy efficiency. Trigeneration expands on this concept by generating electricity, heat, and cooling, typically through an absorption chiller, providing comprehensive energy solutions for Your facility's diverse needs.

Table of Comparison

| Feature | Cogeneration (CHP) | Trigeneration (CCHP) |

|---|---|---|

| Definition | Simultaneous production of electricity and useful heat | Simultaneous production of electricity, heat, and cooling |

| Output | Electricity + Heat | Electricity + Heat + Cooling |

| Efficiency | 60-80% energy efficiency | Up to 90% energy efficiency |

| Applications | Industrial plants, hospitals, campuses | Larger facilities needing cooling: hospitals, data centers, commercial buildings |

| Energy Savings | Reduces fuel consumption by utilizing heat waste | Maximizes energy utilization by adding absorption chillers |

| Emissions | Lower CO2 emissions compared to separate systems | Further emission reductions due to optimized cooling integration |

| Complexity | Moderate system complexity | Higher complexity due to cooling integration |

| Capital Cost | Lower initial investment | Higher initial investment due to additional cooling equipment |

Introduction to Cogeneration and Trigeneration

Cogeneration, also known as combined heat and power (CHP), simultaneously produces electricity and useful heat from a single fuel source, significantly improving overall energy efficiency by capturing waste heat that would otherwise be lost. Trigeneration, or combined cooling, heat, and power (CCHP), extends this concept by adding cooling generation via absorption chillers, utilizing the excess heat to provide air conditioning or refrigeration. Both systems reduce energy costs and carbon emissions by optimizing fuel use in industrial plants, commercial buildings, and institutional facilities.

Core Principles of Cogeneration

Cogeneration, also known as combined heat and power (CHP), simultaneously produces electricity and useful thermal energy from a single fuel source, significantly enhancing energy efficiency by capturing heat that would otherwise be wasted. This core principle optimizes fuel usage, reduces greenhouse gas emissions, and lowers operational costs compared to separate heat and power generation. Understanding these fundamentals helps you evaluate energy solutions that maximize savings and sustainability in industrial or commercial applications.

How Trigeneration Differs from Cogeneration

Trigeneration differs from cogeneration by producing three forms of energy simultaneously: electricity, heat, and cooling, whereas cogeneration generates only electricity and heat. This added cooling output in trigeneration systems enhances overall energy efficiency by utilizing waste heat for refrigeration or air conditioning. Your facility can significantly reduce energy costs and carbon footprint by adopting trigeneration instead of traditional cogeneration.

Energy Efficiency Comparison

Cogeneration systems convert fuel into both electricity and useful heat, achieving energy efficiencies of up to 80-85%. Trigeneration enhances this process by utilizing waste heat for cooling through absorption chillers, pushing overall energy efficiency beyond 90%. Your choice between the two depends on whether cooling demand justifies the added complexity and efficiency gains of trigeneration.

Environmental Impact Assessment

Cogeneration systems improve energy efficiency by producing electricity and heat simultaneously, reducing greenhouse gas emissions and lowering fuel consumption compared to separate generation. Trigeneration further enhances environmental benefits by utilizing waste heat for cooling through absorption chillers, decreasing the reliance on additional electricity and minimizing carbon footprint. Your facility can achieve significant reductions in CO2 emissions and resource use by choosing trigeneration over cogeneration for a comprehensive environmental impact assessment.

Cost and Economic Benefits

Cogeneration systems typically offer lower upfront costs and faster return on investment by producing both electricity and heat simultaneously, maximizing fuel efficiency and reducing energy expenses. Trigeneration adds cooling capabilities, increasing initial installation costs but providing greater economic benefits through enhanced energy savings and operational flexibility in sectors requiring heating, cooling, and power. Your choice depends on budget constraints and specific energy demands, with trigeneration delivering more comprehensive cost savings over time despite higher capital investment.

Technological Components and Integration

Cogeneration systems primarily consist of a gas turbine or reciprocating engine coupled with a heat recovery unit to simultaneously produce electricity and useful thermal energy. Trigeneration extends this setup by incorporating an absorption chiller, enabling the conversion of recovered heat into cooling energy alongside power and heat generation. The integrated design of trigeneration enhances overall system efficiency by utilizing a single fuel source to meet electricity, heating, and cooling demands, optimizing resource use in industrial and commercial applications.

Suitable Applications and Industry Use Cases

Cogeneration is ideal for facilities requiring simultaneous production of electricity and heat, such as manufacturing plants, hospitals, and universities, where waste heat can be effectively utilized for heating or steam generation. Trigeneration extends this concept by producing electricity, heating, and cooling, making it suitable for commercial buildings, data centers, and food processing industries that demand air conditioning alongside thermal energy. Both systems enhance energy efficiency and reduce operational costs, with cogeneration favoring industries with high thermal demand and trigeneration benefiting those needing comprehensive climate control solutions.

Challenges and Limitations

Cogeneration systems face challenges such as limited fuel flexibility and potential inefficiencies during fluctuating demand, while trigeneration adds complexity with the need to balance simultaneous production of electricity, heating, and cooling. Maintenance costs and higher initial capital investments pose significant limitations for both technologies, with trigeneration requiring more sophisticated control systems to optimize combined outputs. Your decision should consider site-specific energy demands and integration capabilities to effectively address these operational challenges.

Future Trends in Cogeneration and Trigeneration

Future trends in cogeneration and trigeneration emphasize increased integration with renewable energy sources and advancements in energy storage technologies to boost efficiency and reduce emissions. Emerging digital control systems and smart grids optimize the real-time operation of these plants, enhancing energy management and cost savings. Your adoption of trigeneration systems could leverage waste heat recovery not only for electricity and heating but also for cooling, positioning your energy strategy at the forefront of sustainable innovation.

Cogeneration vs Trigeneration Infographic

libmatt.com

libmatt.com