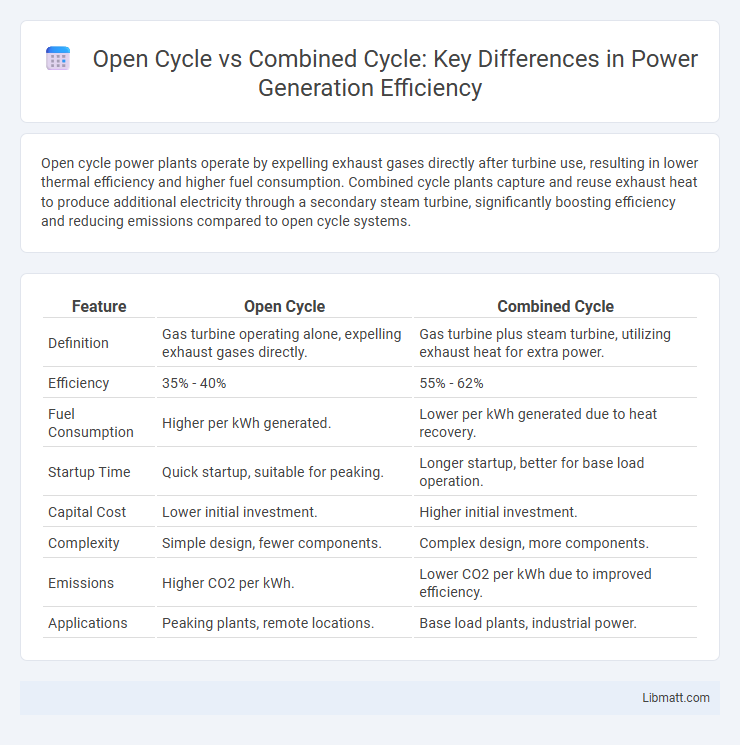

Open cycle power plants operate by expelling exhaust gases directly after turbine use, resulting in lower thermal efficiency and higher fuel consumption. Combined cycle plants capture and reuse exhaust heat to produce additional electricity through a secondary steam turbine, significantly boosting efficiency and reducing emissions compared to open cycle systems.

Table of Comparison

| Feature | Open Cycle | Combined Cycle |

|---|---|---|

| Definition | Gas turbine operating alone, expelling exhaust gases directly. | Gas turbine plus steam turbine, utilizing exhaust heat for extra power. |

| Efficiency | 35% - 40% | 55% - 62% |

| Fuel Consumption | Higher per kWh generated. | Lower per kWh generated due to heat recovery. |

| Startup Time | Quick startup, suitable for peaking. | Longer startup, better for base load operation. |

| Capital Cost | Lower initial investment. | Higher initial investment. |

| Complexity | Simple design, fewer components. | Complex design, more components. |

| Emissions | Higher CO2 per kWh. | Lower CO2 per kWh due to improved efficiency. |

| Applications | Peaking plants, remote locations. | Base load plants, industrial power. |

Introduction to Power Generation Cycles

Open cycle power generation relies on gas turbines where exhaust gases are released directly into the atmosphere after driving the turbine, resulting in lower thermal efficiency around 30-40%. Combined cycle power plants integrate both gas and steam turbines, using waste heat from the gas turbine exhaust to generate steam and drive a steam turbine, which boosts overall efficiency to 50-60%. The combined cycle system is favored for its superior fuel utilization, reduced emissions, and enhanced power output compared to the simple open cycle design.

What is an Open Cycle Power Plant?

An Open Cycle Power Plant, also known as a simple cycle gas turbine plant, generates electricity by burning fuel to produce high-temperature gas that spins a turbine connected to a generator. These plants offer quick start-up times and are often used for peak power demand but have lower thermal efficiency, typically around 30-40%, compared to combined cycle plants. Your choice of power plant can impact operational costs and environmental emissions, as open cycle systems emit more CO2 per unit of electricity generated due to less efficient fuel use.

Understanding Combined Cycle Power Plants

Combined cycle power plants maximize efficiency by combining gas and steam turbines, utilizing waste heat from the gas turbine to generate additional power with a steam turbine. Unlike open cycle plants that only use a gas turbine and have lower thermal efficiency, combined cycle plants can achieve efficiencies exceeding 60%. Understanding combined cycle systems helps you optimize energy output and reduce fuel consumption in power generation.

Key Components of Open and Combined Cycles

Open cycle power plants primarily consist of gas turbines, compressors, and combustion chambers, utilizing air and fuel to generate electricity rapidly without heat recovery mechanisms. Combined cycle plants integrate both gas and steam turbines connected via a heat recovery steam generator (HRSG), which captures exhaust heat from the gas turbine to produce steam and drive the steam turbine, significantly improving efficiency. Understanding these key components helps you assess the operational advantages and efficiency gains of combined cycle systems over open cycle configurations.

Efficiency Comparison: Open Cycle vs Combined Cycle

Combined Cycle power plants achieve efficiency levels of up to 60% by utilizing both gas and steam turbines to convert fuel into electricity, whereas Open Cycle plants typically reach efficiencies around 35-40% due to energy loss in exhaust gases. The integration of waste heat recovery in Combined Cycle systems significantly reduces fuel consumption and operational costs, making them more environmentally friendly compared to Open Cycle setups. Your choice between the two directly impacts fuel efficiency, emissions, and overall power generation cost-effectiveness.

Environmental Impact Assessment

Open cycle power plants typically have higher greenhouse gas emissions due to lower efficiency and more fuel consumption per unit of electricity generated. Combined cycle plants utilize waste heat recovery, significantly reducing carbon emissions and improving overall environmental performance. Understanding these differences can help you make informed decisions in assessing the environmental impact of power generation projects.

Application Areas and Industry Usage

Open cycle gas turbines are commonly used in peaking power plants and emergency power generation due to their quick start-up capabilities and lower initial costs. Combined cycle power plants dominate large-scale utility and industrial power generation sectors, delivering higher efficiency and better fuel economy by integrating gas and steam turbines. Your choice between these cycles depends on operational needs, with open cycle favored for flexibility and combined cycle preferred for continuous, high-efficiency power production.

Investment and Operating Costs

Open cycle power plants generally require lower initial investment due to simpler technology and faster construction times, but their operating costs are higher because of less efficient fuel consumption and increased fuel expenditure. Combined cycle plants demand a higher capital investment, driven by the integration of gas and steam turbines, yet they benefit from significantly reduced fuel costs and superior thermal efficiency, lowering overall operational expenses. Over the plant's lifecycle, combined cycle technology offers more cost-effective energy production despite the upfront investment premium.

Advantages and Disadvantages of Each Cycle

Open cycle gas turbines offer advantages such as quicker start-up times and lower initial costs, making them ideal for peak power demand and mobile applications, but their thermal efficiency is generally lower, often around 30-40%. Combined cycle plants improve efficiency significantly, reaching up to 60%, by utilizing waste heat from the gas turbine to power a steam turbine, which reduces fuel consumption and emissions; however, they involve higher capital investment, longer start-up times, and greater operational complexity. The choice between open cycle and combined cycle depends on factors like operational flexibility, fuel cost, environmental regulations, and specific energy demand profiles.

Future Trends in Power Generation Technologies

Future trends in power generation technologies emphasize increased efficiency and reduced emissions, with combined cycle power plants gaining prominence due to their higher thermal efficiency of up to 60% compared to 33-40% for open cycle systems. Innovations in combined cycle gas turbines (CCGT) integrate advanced materials and digital controls, enabling flexible operation alongside renewable energy sources. The shift toward decarbonization and grid stability drives investments in hybrid systems combining combined cycle plants with energy storage and hydrogen fuel blending.

Open Cycle vs Combined Cycle Infographic

libmatt.com

libmatt.com