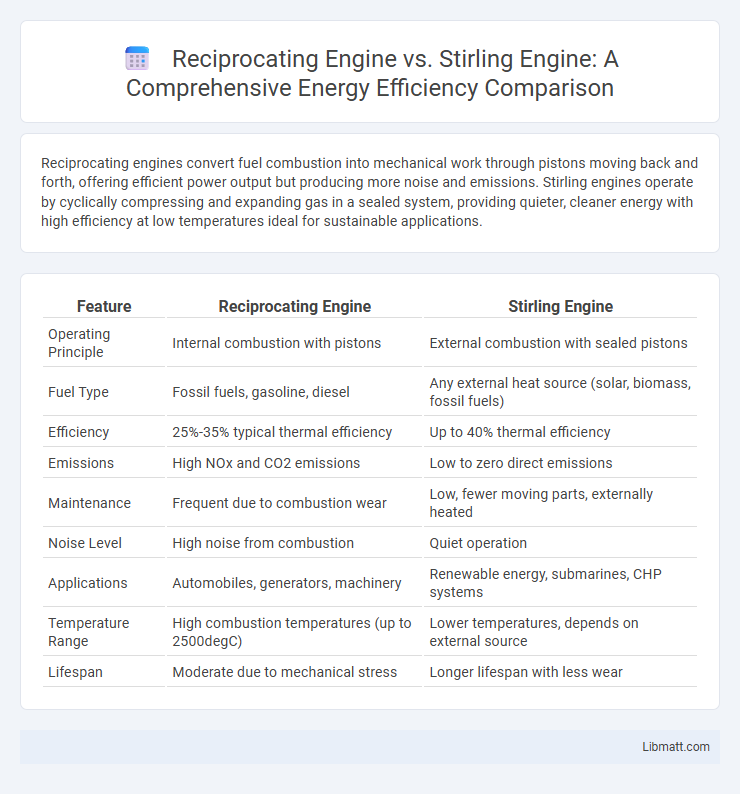

Reciprocating engines convert fuel combustion into mechanical work through pistons moving back and forth, offering efficient power output but producing more noise and emissions. Stirling engines operate by cyclically compressing and expanding gas in a sealed system, providing quieter, cleaner energy with high efficiency at low temperatures ideal for sustainable applications.

Table of Comparison

| Feature | Reciprocating Engine | Stirling Engine |

|---|---|---|

| Operating Principle | Internal combustion with pistons | External combustion with sealed pistons |

| Fuel Type | Fossil fuels, gasoline, diesel | Any external heat source (solar, biomass, fossil fuels) |

| Efficiency | 25%-35% typical thermal efficiency | Up to 40% thermal efficiency |

| Emissions | High NOx and CO2 emissions | Low to zero direct emissions |

| Maintenance | Frequent due to combustion wear | Low, fewer moving parts, externally heated |

| Noise Level | High noise from combustion | Quiet operation |

| Applications | Automobiles, generators, machinery | Renewable energy, submarines, CHP systems |

| Temperature Range | High combustion temperatures (up to 2500degC) | Lower temperatures, depends on external source |

| Lifespan | Moderate due to mechanical stress | Longer lifespan with less wear |

Introduction: Reciprocating Engine vs Stirling Engine

Reciprocating engines operate using the combustion of fuel inside cylinders to move pistons in a back-and-forth motion, converting thermal energy into mechanical work. Stirling engines function based on external heat sources, utilizing a closed-cycle system where gas expands and contracts to drive a piston without internal combustion. Your choice between these engines depends on factors like fuel availability, efficiency needs, and application requirements.

Basic Working Principles

Reciprocating engines operate by converting the linear motion of pistons into rotational motion through the combustion of fuel inside cylinders, generating power in discrete power strokes. Stirling engines utilize external heat sources to cyclically compress and expand a working gas, transferring heat through a regenerator to produce mechanical work with minimal emissions. Your choice between these engines depends on fuel availability, efficiency requirements, and environmental considerations.

Core Components Comparison

Reciprocating engines rely on pistons, cylinders, valves, and a crankshaft to convert combustion energy into mechanical motion, while Stirling engines utilize pistons, displacers, and external heat sources to drive cyclic gas expansion and compression. The reciprocating engine's core components are exposed to internal combustion stresses and require complex valve timing systems, contrasting with the Stirling engine's sealed working gas and fewer moving parts, which result in quieter operation and lower maintenance. Your choice between these engines should consider the mechanical simplicity and external heat flexibility of Stirling engines versus the higher power density and established fuel use of reciprocating engines.

Efficiency and Performance

Reciprocating engines typically achieve higher power density and quicker response times, making them suitable for automotive and industrial applications where performance is critical. Stirling engines offer superior thermal efficiency due to their external combustion process, which allows for continuous heat input and lower emissions, ideal for renewable energy and low-noise environments. Your choice depends on whether you prioritize immediate power output or long-term fuel efficiency and environmental impact.

Fuel Flexibility and Energy Sources

Reciprocating engines exhibit high fuel flexibility, efficiently operating on gasoline, diesel, natural gas, and biofuels, catering to diverse energy sources for varied applications. Stirling engines primarily utilize external heat sources, allowing the use of renewable energy such as solar, biomass, and waste heat, enhancing sustainability and reducing dependence on fossil fuels. Their distinct fuel adaptability highlights the reciprocating engine's practicality for conventional fuels and the Stirling engine's strength in leveraging alternative energy sources.

Maintenance and Reliability

Reciprocating engines require more frequent maintenance due to numerous moving parts subject to wear, including pistons, valves, and crankshafts, which can impact long-term reliability. Stirling engines have fewer moving components and operate with external combustion, resulting in lower maintenance needs and higher reliability over extended periods. Your choice depends on balancing the simplicity and durability of Stirling engines against the widespread availability and repair infrastructure for reciprocating engines.

Environmental Impact

Reciprocating engines typically produce higher emissions of nitrogen oxides, carbon monoxide, and unburned hydrocarbons due to combustion processes, contributing to air pollution and environmental degradation. Stirling engines operate on external combustion with high thermal efficiency and lower emissions, making them a cleaner alternative that reduces your carbon footprint. Their ability to use renewable or waste heat sources further enhances their environmental sustainability compared to traditional reciprocating engines.

Noise and Vibration Levels

Reciprocating engines typically generate higher noise and vibration levels due to the rapid movement of pistons and combustion events, leading to mechanical and acoustic disturbances. Stirling engines operate with external combustion and employ smooth, continuous piston motion, resulting in significantly lower noise and vibration outputs. These characteristics make Stirling engines more suitable for applications requiring quieter and smoother operation.

Applications and Industry Use Cases

Reciprocating engines dominate automotive, aerospace, and heavy machinery due to high power output and efficiency in internal combustion processes. Stirling engines find niche applications in renewable energy, submarines, and remote power generation thanks to their quiet operation, fuel flexibility, and low emissions. Industrial use cases for reciprocating engines include transportation and construction equipment, while Stirling engines are preferred in solar power plants and specialized cooling systems.

Future Trends and Developments

Reciprocating engines continue to evolve with advancements in fuel efficiency and emission reduction technologies, integrating hybrid-electric systems for improved sustainability. Stirling engines are gaining attention for their potential in renewable energy applications due to their ability to operate on various heat sources, including solar and waste heat. Future developments emphasize enhanced materials and smart control systems to boost performance and durability in both engine types.

Reciprocating Engine vs Stirling Engine Infographic

libmatt.com

libmatt.com