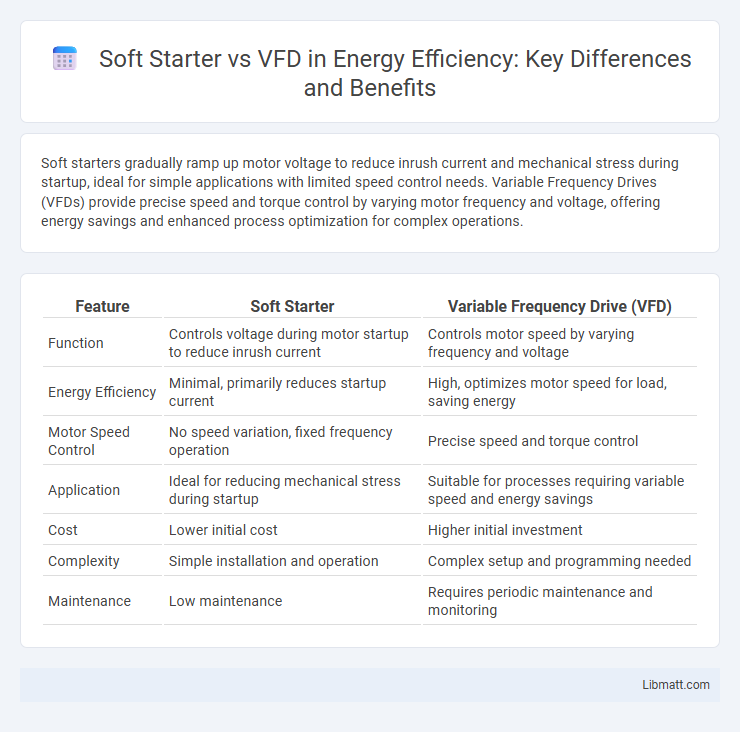

Soft starters gradually ramp up motor voltage to reduce inrush current and mechanical stress during startup, ideal for simple applications with limited speed control needs. Variable Frequency Drives (VFDs) provide precise speed and torque control by varying motor frequency and voltage, offering energy savings and enhanced process optimization for complex operations.

Table of Comparison

| Feature | Soft Starter | Variable Frequency Drive (VFD) |

|---|---|---|

| Function | Controls voltage during motor startup to reduce inrush current | Controls motor speed by varying frequency and voltage |

| Energy Efficiency | Minimal, primarily reduces startup current | High, optimizes motor speed for load, saving energy |

| Motor Speed Control | No speed variation, fixed frequency operation | Precise speed and torque control |

| Application | Ideal for reducing mechanical stress during startup | Suitable for processes requiring variable speed and energy savings |

| Cost | Lower initial cost | Higher initial investment |

| Complexity | Simple installation and operation | Complex setup and programming needed |

| Maintenance | Low maintenance | Requires periodic maintenance and monitoring |

Introduction to Soft Starters and VFDs

Soft Starters and Variable Frequency Drives (VFDs) are essential motor control devices used to manage the starting and operation of electric motors. Soft Starters gradually increase voltage to reduce inrush current during startup, minimizing mechanical stress and electrical surges. VFDs, on the other hand, provide precise control over motor speed and torque by varying the frequency and voltage supplied, enhancing energy efficiency and process optimization for your applications.

How Soft Starters Work

Soft starters control the initial voltage supplied to an electric motor, gradually ramping it up to reduce inrush current and mechanical stress during startup. By using thyristors to modulate voltage, they ensure smooth acceleration without altering motor speed or torque during normal operation. Your motor benefits from minimized wear and extended lifespan due to these controlled startup characteristics.

How Variable Frequency Drives (VFDs) Operate

Variable Frequency Drives (VFDs) control motor speed by adjusting the frequency and voltage supplied to the electric motor, enabling precise speed regulation and energy savings. Unlike soft starters, which only limit the initial inrush current during startup, VFDs provide continuous speed control throughout operation. This capability allows VFDs to optimize motor performance, reduce mechanical stress, and enhance process efficiency in various industrial applications.

Key Differences Between Soft Starters and VFDs

Soft starters primarily control motor voltage during startup to reduce inrush current, while Variable Frequency Drives (VFDs) adjust both voltage and frequency for precise speed control throughout operation. Soft starters are ideal for applications requiring simple torque control and reduced mechanical stress, whereas VFDs offer advanced energy savings, variable speed control, and improved process optimization. Understanding these key differences helps you select the right motor control solution based on your operational needs and efficiency goals.

Applications Best Suited for Soft Starters

Soft starters are best suited for applications requiring reduced inrush current and controlled starting torque, such as pumps, fans, and conveyors. These devices effectively minimize mechanical stress and electrical disturbances during motor startup without variable speed control. Industries prioritizing smooth motor acceleration and cost-efficient motor protection commonly choose soft starters over VFDs.

Applications Ideal for VFDs

VFDs (Variable Frequency Drives) excel in applications requiring precise speed control, energy savings, and smooth acceleration/deceleration, such as conveyor systems, pumps, HVAC fans, and machine tools. They are ideal for processes demanding variable torque and high startup torque with minimal mechanical stress. VFDs also enable advanced process automation and integration with complex control systems, making them preferred in industries like manufacturing, water treatment, and HVAC.

Energy Efficiency: Soft Starter vs VFD

Variable Frequency Drives (VFDs) provide superior energy efficiency compared to soft starters by continuously adjusting motor speed to match load requirements, significantly reducing power consumption during partial load conditions. Soft starters primarily minimize inrush current and mechanical stress during startup but lack the ability to modulate motor speed, resulting in higher energy usage at constant full-speed operation. Implementing VFDs in applications with variable demand can lead to energy savings of up to 30%, whereas soft starters offer limited efficiency gains.

Cost Comparison and ROI Analysis

Soft starters typically have lower initial costs compared to Variable Frequency Drives (VFDs), making them a budget-friendly option for applications requiring simple start and stop control. VFDs, while more expensive upfront, offer energy savings through speed control, resulting in a better long-term ROI, especially in processes with variable load demands. Your investment in a VFD can lead to substantial energy cost reductions and enhanced motor lifespan, which may justify the higher initial expenditure over time.

Maintenance and Reliability Considerations

Soft starters require less maintenance due to fewer electronic components and simpler circuitry, reducing the risk of failures compared to Variable Frequency Drives (VFDs). VFDs offer enhanced reliability in precise motor control but demand regular inspection of cooling systems, capacitors, and power semiconductors to prevent downtime. Optimal maintenance strategies for both devices involve scheduled thermal management and firmware updates to ensure long-term operational stability.

Choosing the Right Motor Control Solution

Selecting the right motor control solution depends on the application requirements; soft starters provide smooth starting and reduced inrush current for induction motors, ideal for simple start-stop operations with moderate control needs. Variable Frequency Drives (VFDs) offer precise speed control, energy savings, and enhanced process automation, making them suitable for applications demanding variable speed or torque control. Consider factors such as motor type, load characteristics, energy efficiency goals, and control complexity when choosing between soft starters and VFDs.

Soft Starter vs VFD Infographic

libmatt.com

libmatt.com