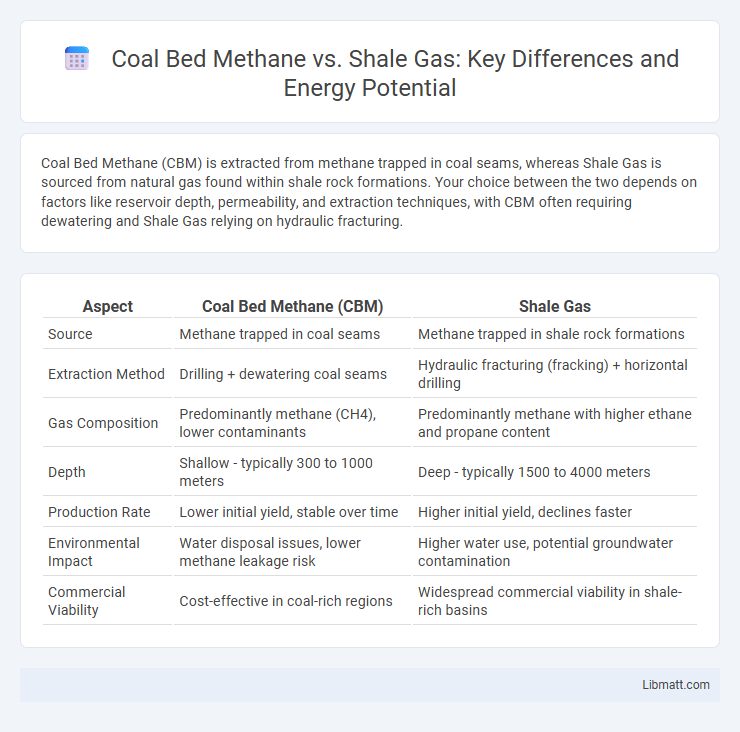

Coal Bed Methane (CBM) is extracted from methane trapped in coal seams, whereas Shale Gas is sourced from natural gas found within shale rock formations. Your choice between the two depends on factors like reservoir depth, permeability, and extraction techniques, with CBM often requiring dewatering and Shale Gas relying on hydraulic fracturing.

Table of Comparison

| Aspect | Coal Bed Methane (CBM) | Shale Gas |

|---|---|---|

| Source | Methane trapped in coal seams | Methane trapped in shale rock formations |

| Extraction Method | Drilling + dewatering coal seams | Hydraulic fracturing (fracking) + horizontal drilling |

| Gas Composition | Predominantly methane (CH4), lower contaminants | Predominantly methane with higher ethane and propane content |

| Depth | Shallow - typically 300 to 1000 meters | Deep - typically 1500 to 4000 meters |

| Production Rate | Lower initial yield, stable over time | Higher initial yield, declines faster |

| Environmental Impact | Water disposal issues, lower methane leakage risk | Higher water use, potential groundwater contamination |

| Commercial Viability | Cost-effective in coal-rich regions | Widespread commercial viability in shale-rich basins |

Introduction to Coal Bed Methane and Shale Gas

Coal Bed Methane (CBM) is natural gas extracted from coal seams, primarily composed of methane stored within the coal's porous structure. Shale Gas, on the other hand, is natural gas trapped within fine-grained sedimentary rocks called shale formations, known for its significant global reserves. Understanding the distinctions between your coal bed methane and shale gas sources is crucial for optimizing extraction techniques and energy production.

Geological Formation and Source Differences

Coal Bed Methane (CBM) originates from methane gas adsorbed within the micropores of coal seams formed primarily during the Carboniferous period, characterized by compacted plant debris under low thermal maturity conditions. Shale Gas is trapped within fine-grained sedimentary rock formations, typically organic-rich shales from the Devonian to Cretaceous periods, generated through thermal maturation of kerogen. CBM extraction targets fractures and cleats in coal seams, while Shale Gas production relies on hydraulic fracturing of impermeable shale matrix and organic-rich source rocks.

Extraction Techniques Compared

Coal Bed Methane extraction involves dewatering coal seams to reduce pressure and release methane trapped in the coal matrix, primarily utilizing vertical wells with pumping systems. Shale Gas extraction relies on hydraulic fracturing combined with horizontal drilling to create fractures in low-permeability shale formations, enhancing gas flow to the wellbore. The distinct geological settings dictate that Coal Bed Methane extraction is less reliant on fracturing, while Shale Gas requires advanced stimulation techniques to access diffusely distributed adsorbed gas.

Reservoir Characteristics and Gas Content

Coal Bed Methane (CBM) reservoirs are characterized by porous coal seams with natural fractures, providing gas storage primarily through adsorption on the coal surface, typically exhibiting moderate gas content ranging from 100 to 400 standard cubic feet per ton (scf/ton). Shale Gas reservoirs consist of fine-grained sedimentary rocks with low permeability, where gas is stored in free form within pore spaces and as adsorbed gas, with gas contents varying widely but often exceeding 2000 cubic feet per ton. The differing reservoir properties influence extraction techniques, with CBM requiring dewatering to reduce pressure and release adsorbed gas, while shale gas extraction relies on hydraulic fracturing to enhance permeability.

Environmental Impact Analysis

Coal bed methane (CBM) extraction generally results in lower greenhouse gas emissions compared to shale gas due to its lower carbon content and reduced need for hydraulic fracturing. Shale gas production often involves extensive fracking, which poses significant risks of groundwater contamination, induced seismicity, and higher water usage. Life cycle assessments indicate CBM has a smaller environmental footprint, but both require stringent management to mitigate methane leakage and ecosystem disruption.

Production Efficiency and Economic Viability

Coal Bed Methane (CBM) production generally yields lower gas volumes per well compared to Shale Gas, impacting overall production efficiency. Shale Gas extraction benefits from advanced hydraulic fracturing, resulting in higher initial production rates and longer well lifespans, enhancing economic viability. Your investment in Shale Gas typically offers greater returns due to higher energy output and more established infrastructure, while CBM provides a supplemental resource with moderate cost and environmental challenges.

Challenges in Exploration and Development

Coal Bed Methane exploration faces challenges such as water management due to high water production and the need for dewatering, while Shale Gas extraction encounters difficulties related to hydraulic fracturing in low-permeability rock formations and potential induced seismicity. Both resources require advanced drilling technologies and environmental monitoring to mitigate risks, but Shale Gas development often involves higher operational costs and complex regulatory frameworks. Your decision on resource investment should weigh these technical and environmental factors carefully.

Potential Applications and Market Trends

Coal bed methane (CBM) offers significant potential in industrial heating and power generation due to its consistent gas flow from coal seams, while shale gas is widely used for electricity production and as a feedstock in chemical industries thanks to its abundant reserves and enhanced extraction technologies. Market trends indicate a growing demand for shale gas driven by advancements in hydraulic fracturing and horizontal drilling, whereas CBM sees steady uptake in regions with extensive coal deposits and existing mining infrastructure. Your energy strategy might benefit from evaluating local geological conditions and infrastructure readiness to optimize the integration of these unconventional gas sources.

Regulatory Framework and Safety Concerns

Coal Bed Methane extraction is often subject to stricter regulatory frameworks due to groundwater contamination risks, requiring comprehensive water management plans and methane emission controls. Shale Gas operations typically face rigorous regulations on hydraulic fracturing fluids and seismic activity monitoring to address potential well integrity and induced seismicity hazards. Understanding these safety concerns can help you navigate compliance and risk mitigation strategies effectively in both industries.

Future Outlook: Coal Bed Methane vs Shale Gas

Coal Bed Methane (CBM) extraction faces challenges due to environmental concerns and limited reserves, potentially slowing its future growth compared to Shale Gas. Shale Gas continues to attract significant investment globally because of advanced hydraulic fracturing technologies and vast untapped formations, especially in North America and Asia. Market projections indicate Shale Gas will dominate natural gas production, driven by higher yields and evolving policies favoring cleaner energy sources.

Coal Bed Methane vs Shale Gas Infographic

libmatt.com

libmatt.com