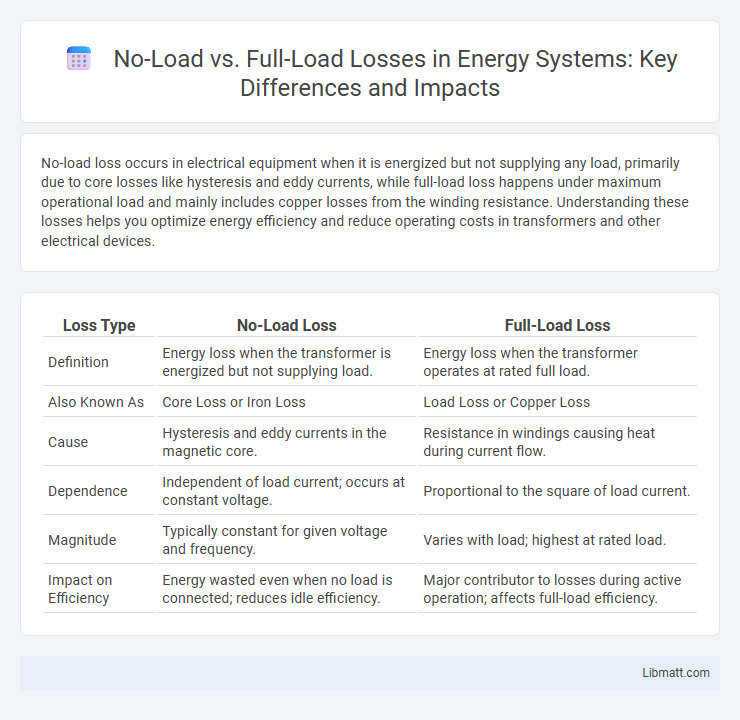

No-load loss occurs in electrical equipment when it is energized but not supplying any load, primarily due to core losses like hysteresis and eddy currents, while full-load loss happens under maximum operational load and mainly includes copper losses from the winding resistance. Understanding these losses helps you optimize energy efficiency and reduce operating costs in transformers and other electrical devices.

Table of Comparison

| Loss Type | No-Load Loss | Full-Load Loss |

|---|---|---|

| Definition | Energy loss when the transformer is energized but not supplying load. | Energy loss when the transformer operates at rated full load. |

| Also Known As | Core Loss or Iron Loss | Load Loss or Copper Loss |

| Cause | Hysteresis and eddy currents in the magnetic core. | Resistance in windings causing heat during current flow. |

| Dependence | Independent of load current; occurs at constant voltage. | Proportional to the square of load current. |

| Magnitude | Typically constant for given voltage and frequency. | Varies with load; highest at rated load. |

| Impact on Efficiency | Energy wasted even when no load is connected; reduces idle efficiency. | Major contributor to losses during active operation; affects full-load efficiency. |

Introduction to Electrical Losses

Electrical losses in transformers primarily occur as no-load losses and full-load losses. No-load losses, also known as core losses, happen due to the magnetizing current flowing in the transformer core, remaining constant regardless of load conditions. Full-load losses, or copper losses, arise from the resistance in the windings when current passes through, varying directly with the load on the transformer.

Defining No-load Losses

No-load losses, also known as core losses, occur in electrical transformers when the device is energized but not supplying any load, primarily due to hysteresis and eddy currents in the core. These losses depend on the magnetic properties of the transformer's core material and are relatively constant regardless of the load level. Understanding no-load losses helps you optimize transformer efficiency by identifying energy wasted during idle operation.

Understanding Full-load Losses

Full-load losses, also known as copper losses, occur when electrical current flows through the transformer winding under full load conditions, causing resistive heating proportional to the square of the load current. These losses increase with load and directly impact the transformer's efficiency during operation, primarily driven by the resistance of the conductors in the windings. Accurate assessment of full-load losses is essential for optimizing transformer design and energy efficiency in electrical power systems.

Key Differences Between No-load and Full-load Losses

No-load loss primarily occurs in the transformer's core due to magnetizing current and remains relatively constant regardless of load. Full-load loss, also known as copper loss, depends on the load current and mainly results from the resistance of the transformer's windings. Understanding these key differences is crucial for optimizing transformer efficiency and reducing operational costs.

Factors Affecting No-load Losses

No-load losses primarily arise from core losses, which include hysteresis and eddy current losses in the transformer's magnetic core. Factors affecting no-load losses include the quality of the core material, frequency of the applied voltage, and the magnetic flux density within the core. Minimizing these losses involves using high-grade silicon steel and optimizing core design to reduce hysteresis and eddy currents under steady voltage conditions.

Factors Impacting Full-load Losses

Full-load losses in electrical transformers primarily depend on conductor resistance, magnetic core properties, and operational temperature. These losses increase with higher current flow and are influenced by factors such as conductor material, cross-sectional area, and quality of magnetic steel used in the core. Your transformer's efficiency can be optimized by selecting components with low resistance and high-quality magnetic properties to minimize these full-load losses.

Importance in Transformer Efficiency

No-load loss occurs continuously when a transformer is energized, primarily due to core magnetization, while full-load loss happens during operation and is mainly caused by winding resistance and leakage reactance. Minimizing both losses is crucial for enhancing transformer efficiency, as no-load loss affects energy consumption even at idle, and full-load loss impacts performance under actual load conditions. Understanding the balance between these losses helps you improve energy savings and operational reliability in power systems.

Measurement Techniques for Losses

Measurement techniques for no-load and full-load losses involve distinct procedures to accurately assess transformer efficiency. No-load losses are typically measured by applying rated voltage to the primary winding with the secondary winding open while monitoring core losses, whereas full-load losses are determined by loading the transformer to its rated current and measuring winding resistive losses using wattmeters. Accurate measurement of both loss types is essential to evaluate your transformer's performance and optimize energy consumption.

Practical Implications in Power Systems

No-load loss in power systems primarily occurs in transformers due to core magnetization and remains constant regardless of load, impacting energy efficiency during idle periods. Full-load loss increases with the square of the load current, mainly caused by copper losses in windings, significantly affecting operational costs under high demand. Understanding and minimizing both losses through optimized design and maintenance enhances overall system reliability and reduces electricity costs.

Minimizing Losses: Best Practices

Minimizing no-load and full-load losses in electrical transformers involves selecting high-quality core materials with low hysteresis and eddy current losses to reduce no-load losses. Employing optimized winding designs with appropriate conductor sizes and insulation minimizes full-load losses caused by resistance and leakage reactance. Regular maintenance and monitoring of operating conditions ensure sustained efficiency by preventing overheating and insulation degradation, ultimately extending transformer lifespan and reducing energy costs.

No-load vs Full-load Loss Infographic

libmatt.com

libmatt.com