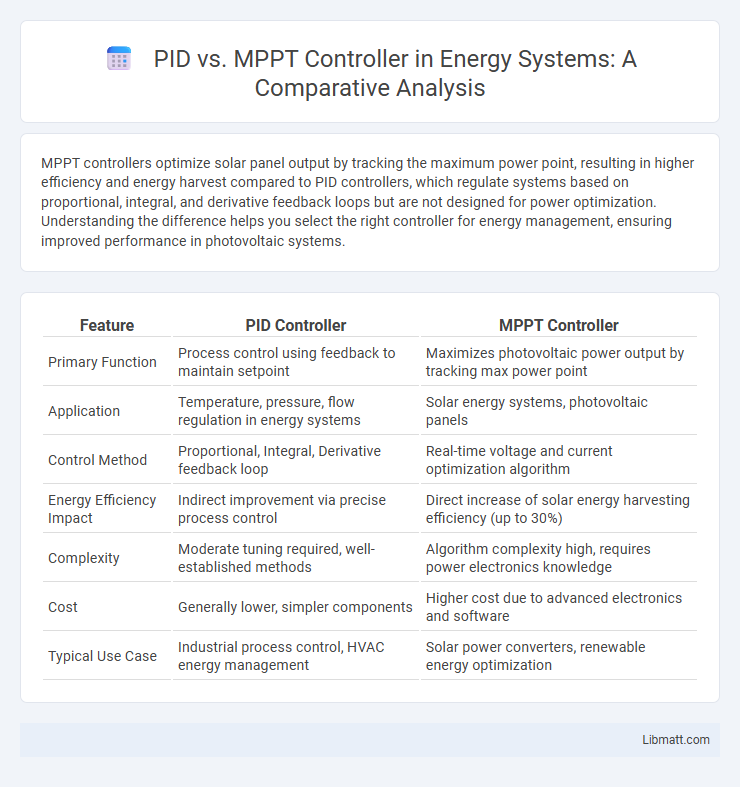

MPPT controllers optimize solar panel output by tracking the maximum power point, resulting in higher efficiency and energy harvest compared to PID controllers, which regulate systems based on proportional, integral, and derivative feedback loops but are not designed for power optimization. Understanding the difference helps you select the right controller for energy management, ensuring improved performance in photovoltaic systems.

Table of Comparison

| Feature | PID Controller | MPPT Controller |

|---|---|---|

| Primary Function | Process control using feedback to maintain setpoint | Maximizes photovoltaic power output by tracking max power point |

| Application | Temperature, pressure, flow regulation in energy systems | Solar energy systems, photovoltaic panels |

| Control Method | Proportional, Integral, Derivative feedback loop | Real-time voltage and current optimization algorithm |

| Energy Efficiency Impact | Indirect improvement via precise process control | Direct increase of solar energy harvesting efficiency (up to 30%) |

| Complexity | Moderate tuning required, well-established methods | Algorithm complexity high, requires power electronics knowledge |

| Cost | Generally lower, simpler components | Higher cost due to advanced electronics and software |

| Typical Use Case | Industrial process control, HVAC energy management | Solar power converters, renewable energy optimization |

Introduction to PID and MPPT Controllers

PID controllers use proportional, integral, and derivative calculations to regulate system variables, ensuring precise control in processes such as temperature, speed, and flow. MPPT controllers optimize photovoltaic (PV) solar power by continuously adjusting the electrical operating point of the modules to extract maximum possible power. Both controllers play crucial roles in automation and energy systems, with PID focusing on stability and response, while MPPT maximizes energy conversion efficiency.

Core Principles of PID Controllers

PID controllers operate based on three core principles: proportional, integral, and derivative actions. The proportional component adjusts output proportionally to the current error, the integral component accounts for accumulated past errors to eliminate steady-state offset, and the derivative component predicts future error trends to enhance system stability. These combined actions enable precise control in dynamic systems by continuously correcting deviations from desired setpoints.

Fundamentals of MPPT Controllers

MPPT (Maximum Power Point Tracking) controllers optimize solar panel output by continuously adjusting the electrical operating point to extract the highest possible power under varying environmental conditions. They use algorithms such as Perturb and Observe or Incremental Conductance to identify the maximum power point efficiently. Unlike traditional PID (Proportional-Integral-Derivative) controllers focused on system control and error correction, MPPT controllers specialize in energy harvesting optimization for photovoltaic systems.

Key Differences Between PID and MPPT Controllers

PID controllers regulate system output by continuously adjusting control variables based on error values, optimizing processes such as temperature or speed control. MPPT controllers maximize photovoltaic system efficiency by tracking the solar panel's maximum power point under varying environmental conditions, enhancing energy harvest. Unlike PID, MPPT is specialized for solar energy applications, whereas PID offers broader control in diverse industrial systems.

Control Strategies: Tracking and Regulation

PID controllers use proportional, integral, and derivative actions to regulate system output by minimizing error through continuous feedback, offering stable but sometimes slower response to changing conditions. MPPT controllers implement algorithms like Perturb and Observe or Incremental Conductance to dynamically track the maximum power point of photovoltaic arrays, optimizing energy harvest under varying irradiance and temperature. While PID excels in precise regulation for temperature or speed control, MPPT focuses on maximizing power extraction by adjusting voltage or current to align with the photovoltaic system's instantaneous maximum power point.

Application Areas: Where PID and MPPT Excel

PID controllers excel in industrial automation, HVAC systems, and process control where precise temperature, pressure, or flow regulation is critical. MPPT controllers are optimized for solar photovoltaic systems, maximizing energy harvest by adjusting the electrical operating point of solar panels. Your choice hinges on whether you need accurate control in dynamic processes (PID) or efficient solar energy conversion (MPPT).

Efficiency and Performance Comparison

MPPT controllers optimize solar panel output by tracking the maximum power point, resulting in higher efficiency--typically around 95-99%--whereas PID controllers primarily regulate temperature and pressure with less impact on energy conversion efficiency. MPPT technology adjusts voltage to maximize power extraction under varying sunlight conditions, significantly enhancing overall system performance compared to PID's fixed control approach. Your solar energy system benefits more from MPPT controllers when efficiency and maximizing energy yield are critical priorities.

Implementation Challenges and Solutions

PID controllers present implementation challenges such as tuning difficulty and overshoot in dynamic solar conditions, requiring precise parameter adjustment to stabilize output. MPPT controllers face challenges in accurately tracking the maximum power point under rapidly changing irradiance and temperature, necessitating advanced algorithms like incremental conductance or perturb and observe methods. Your solar setup can benefit from hybrid approaches combining PID stability with MPPT efficiency to overcome these limitations and optimize performance.

Selecting the Right Controller for Your System

Selecting the right controller for your system depends on factors such as panel type, system size, and budget constraints. MPPT controllers maximize energy harvest by adjusting voltage to match solar panel output, making them ideal for larger or complex arrays with variable shading or temperature conditions. PID controllers focus on minimizing power loss due to potential-induced degradation, extending panel lifespan and improving efficiency for older or high-voltage solar installations.

Future Trends in Control Technologies

Future trends in control technologies emphasize the integration of hybrid PID and MPPT controllers to enhance energy efficiency and system responsiveness in solar power applications. Advanced algorithms powered by artificial intelligence and machine learning optimize maximum power point tracking beyond traditional MPPT capabilities while maintaining precise process control via PID methods. Your solar energy systems will benefit from predictive analytics and adaptive controls that dynamically adjust to environmental changes, ensuring optimal performance and longevity.

PID vs MPPT Controller Infographic

libmatt.com

libmatt.com